Filter electrical connector and grounding spring leaf thereof

A technology of electrical connectors and connectors, applied in the direction of protective grounding/shielding devices for connecting parts, high-frequency structural connections, etc., can solve problems such as difficulty in ensuring consistent quality, large diameter, inconvenient operation, etc., and achieve good quality consistency , small grounding resistance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

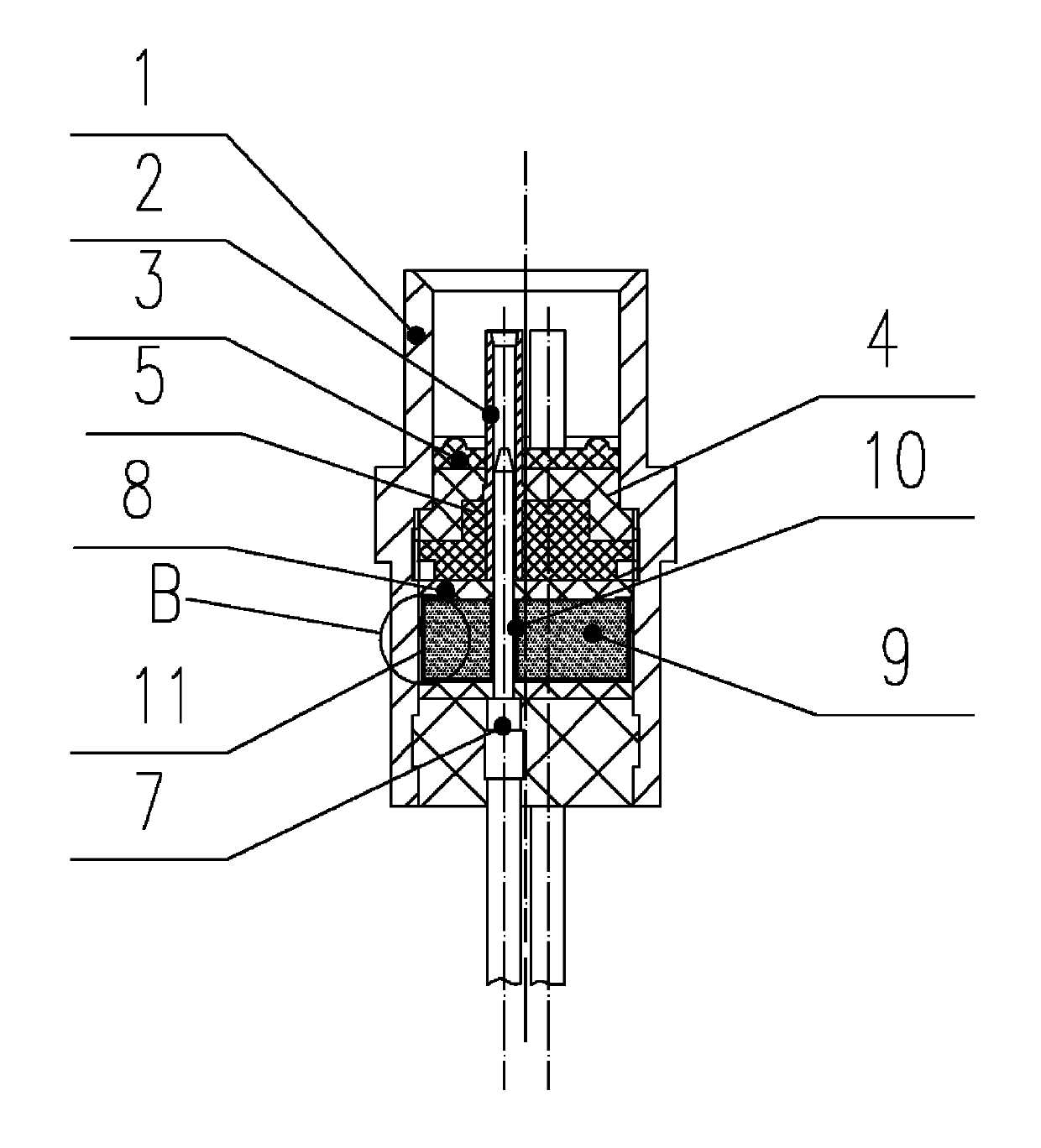

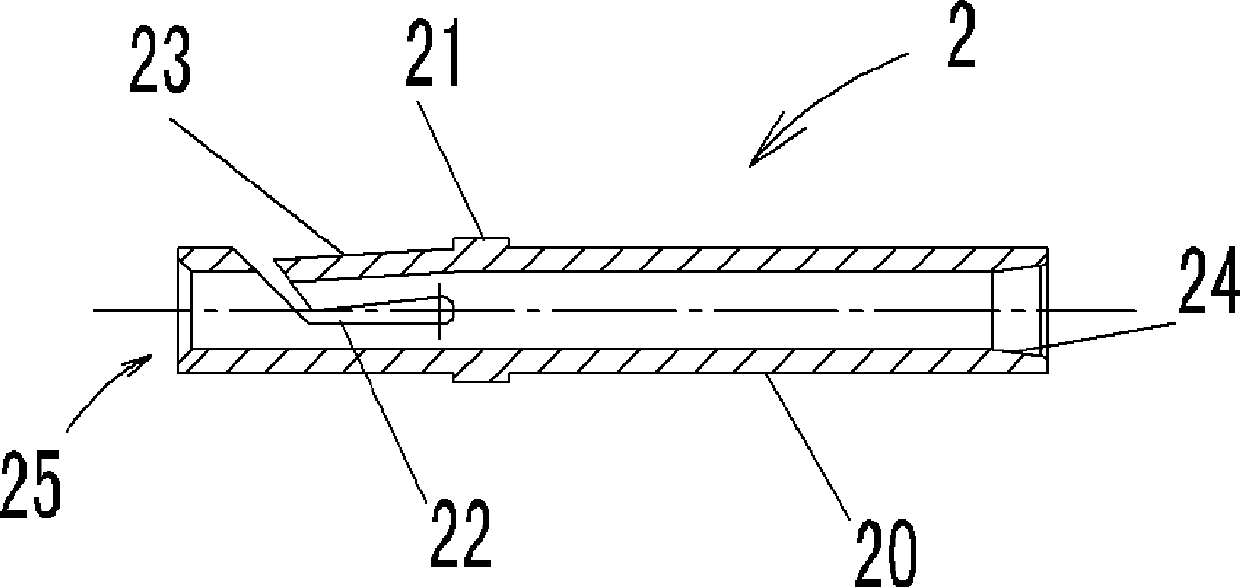

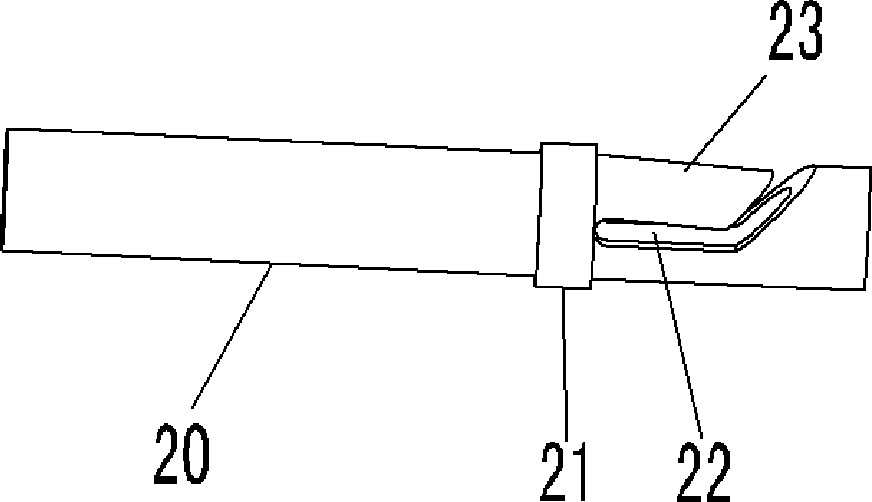

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 9 As shown, Embodiment 1 of the filter electrical connector of the present invention includes a conductive housing 1 and a fixed contact therein, a plate capacitor 9, and the outer electrode of the outer ring of the plate capacitor 9 and the connector housing 1 through a grounding spring The sheet 11 is conductively connected and fixed, and the contact piece is composed of the contact pin 7 and the adapter socket 2 plugged thereon. The plate capacitor 9 is provided with a contact mounting hole for the mating of the pins 7 of each contact. The inner electrode is provided on the inner wall of the contact mounting hole. together. The transfer jack 2 is set on the contact pin 7 and fixed in the housing 1 by the insulating pressure plate 5 and the short insulator 4, the short insulator 4 and the insulating pressure plate 5 are bonded and fixed in the housing 1, and the outer end surface of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com