Automobile panel die design method

A technology for automotive panel and mold design, which is applied in computing, instrumentation, electrical and digital data processing, etc., and can solve problems such as increasing the difficulty of mold debugging, complex structure, and difficulty in deformation under load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] For the drawing die of automobile panels, its main components are upper die, lower die and blank holder. In order to reduce the weight of the mold, these three parts are usually cast and adopt a hollow shell structure. Therefore, the mold structure will undergo elastic deformation under load, which will affect the fitting accuracy of the cavity surface between the upper and lower molds, and ultimately affect the quality of the car. Forming accuracy of the cover.

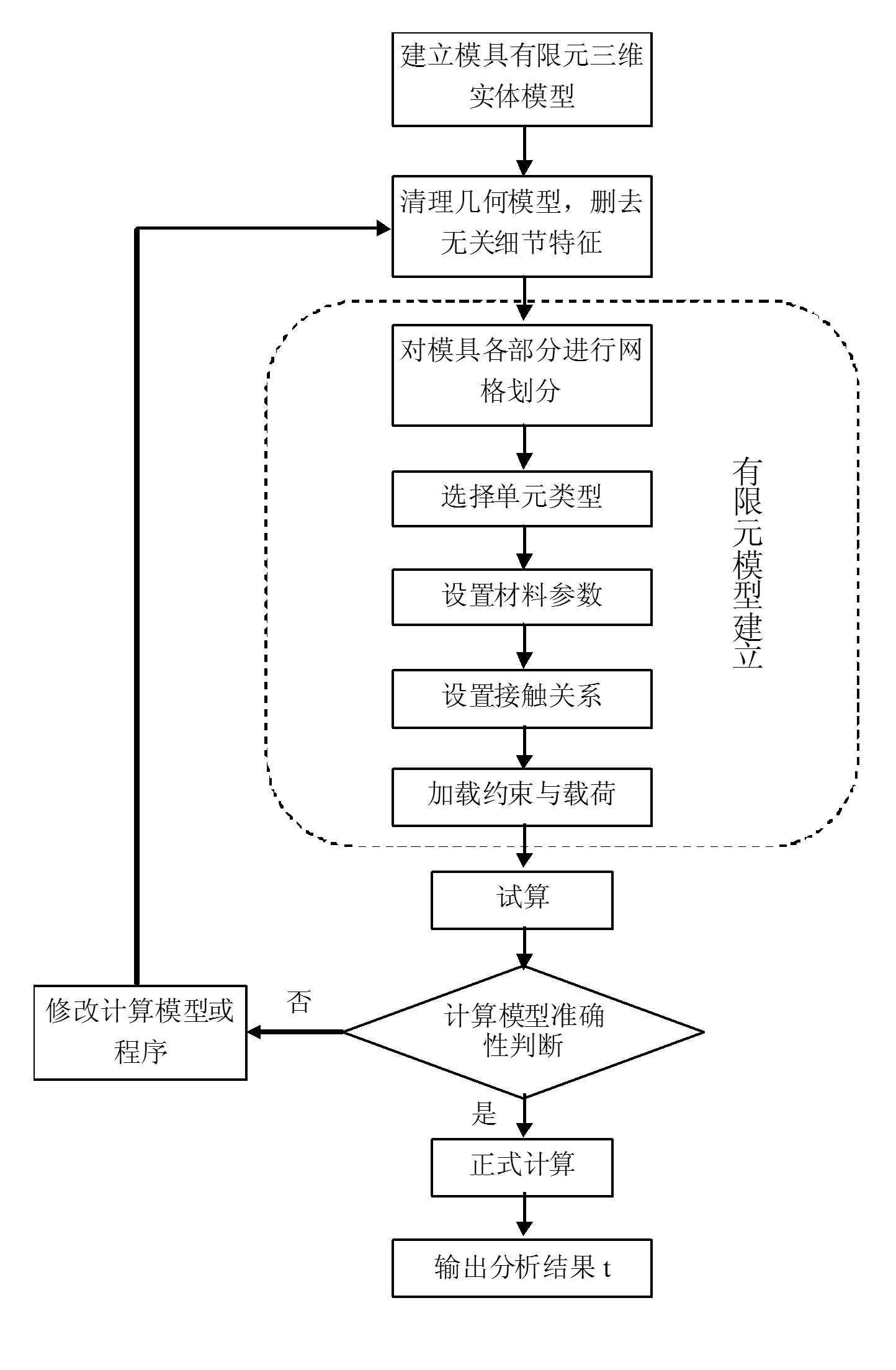

[0020] The present invention just considers that automobile panel mold has such deformation in advance, and it is brought into automobile panel mold design process, as figure 1 As shown, the design steps are:

[0021] (1) Establish the corresponding CAD model of the three-dimensional geometric theory mold according to the geometric structure characteristics of the automobile panel; determine the movement and contact relationship between the various parts of the model;

[0022] (2) Remove the structural featu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com