Supersonic plane mixing layer wind tunnel

A supersonic and mixed layer technology, applied in the wind tunnel field, can solve the problems of reducing the turbulence of the incoming flow, reducing the two-dimensional characteristics of the flow field, and high Reynolds number, so as to eliminate the shock wave of the mixed layer, facilitate the flow field characteristics, and overcome the problems caused by shock wave effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

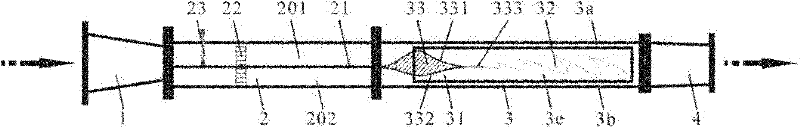

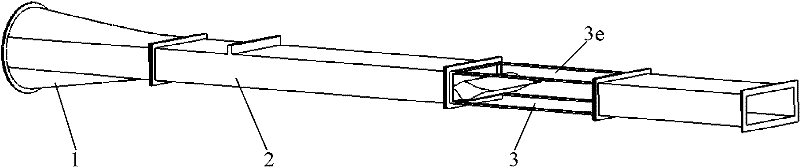

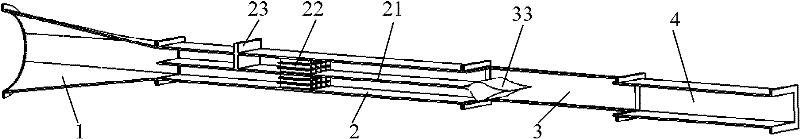

[0040] Such as figure 1As shown, the supersonic planar mixed-layer wind tunnel according to the present invention is mainly composed of a transition section 1, a stabilization section 2, a nozzle experiment section 3 and a diffuser section 4 connected end to end. Transition section 1 is used to introduce air flow, and conduct preliminary rectification to the gas to prepare for its entry into stable section 2. The stabilizing section 2 is connected to the downstream of the transition section 1, and a first partition plate 21 is arranged in the middle of the stabilizing section 2 to divide the inner cavity of the stabilizing section into an upper chamber 201 and a lower chamber 202 for dividing the introduced air flow into two parts. A stable flow of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com