Micro-longhole measuring method based on fiber grating

A fiber grating and measurement method technology, applied in the direction of measurement devices, optical devices, scanning probe microscopy, etc., can solve the problems of limiting ultra-deep hole measurement capabilities, weakening of spot image signals, and unstable force measurement. Achieve the effects of low loss, good spectral characteristics and good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

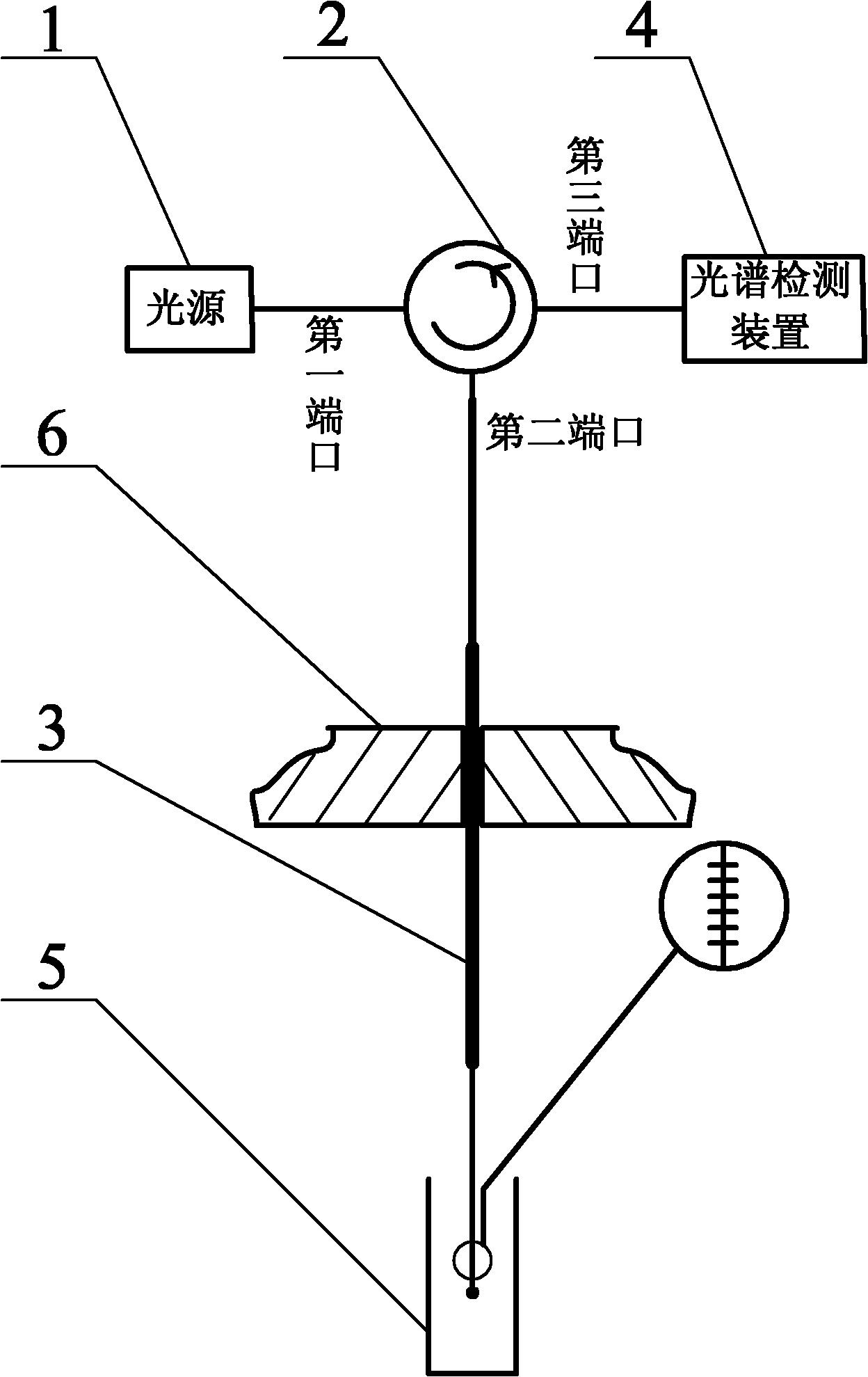

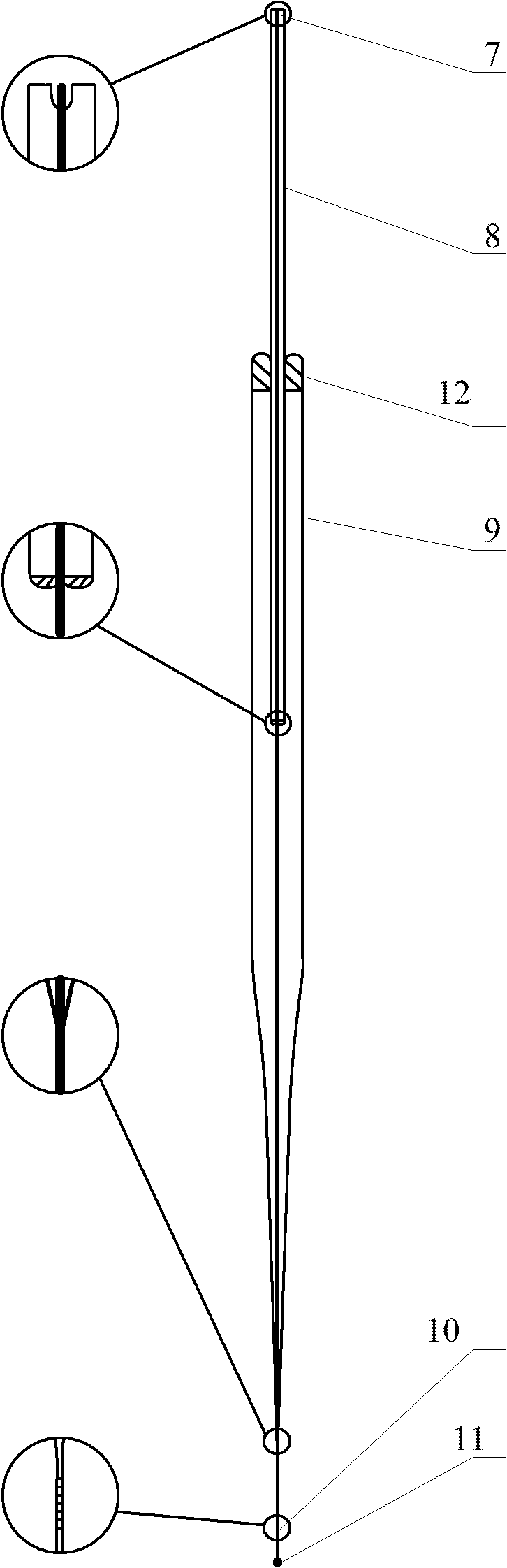

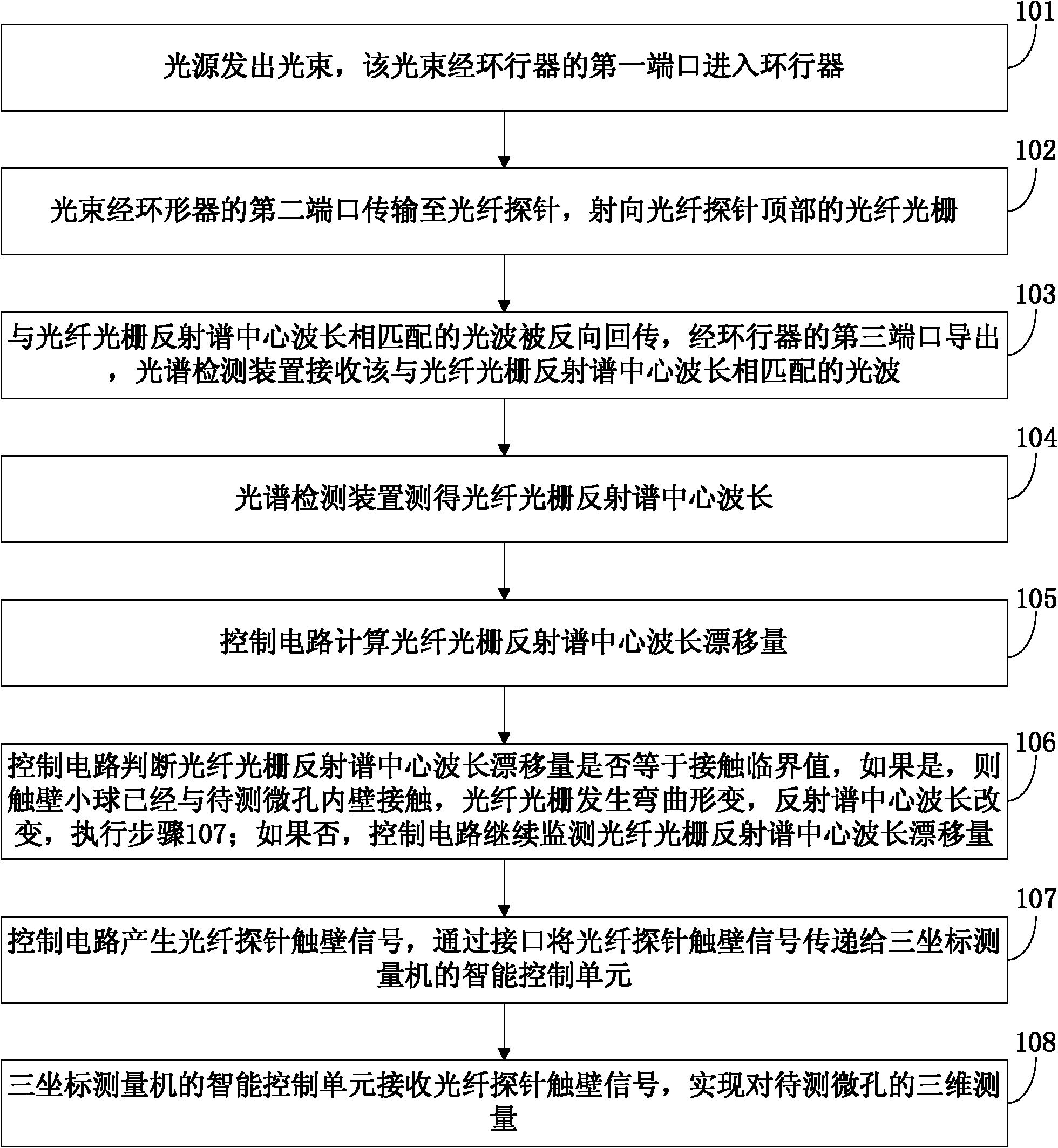

[0039] In order to solve the above problems, improve the precision and accuracy of measurement, and expand the scope of application, the embodiment of the present invention provides a method for measuring micro-deep holes based on fiber gratings, see figure 1 , figure 2 and image 3 , see the description below:

[0040] 101: the light source 1 emits a light beam, and the light beam enters the circulator 2 through the first port of the circulator 2;

[0041] see Figure 4 , the circulator 2 belongs to the three-port optical passive device, there are two transmission paths of the light beam, namely from the first port to the second port and from the second port to the third port, the first port and the third port are input ports resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com