Heat pipe and heat pipe based guide type aluminium electrolysis cell

An aluminum electrolytic cell and heat pipe technology, which is used in indirect heat exchangers, lighting and heating equipment, etc., can solve the problem that cold tanks or aluminum electrolytic cells are weak against thermal disturbances, deteriorate the production environment of aluminum electrolysis workshops, and reduce the life of diversion electrolytic cells. Low problems, to achieve uniform temperature distribution in the tank, improve heat utilization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

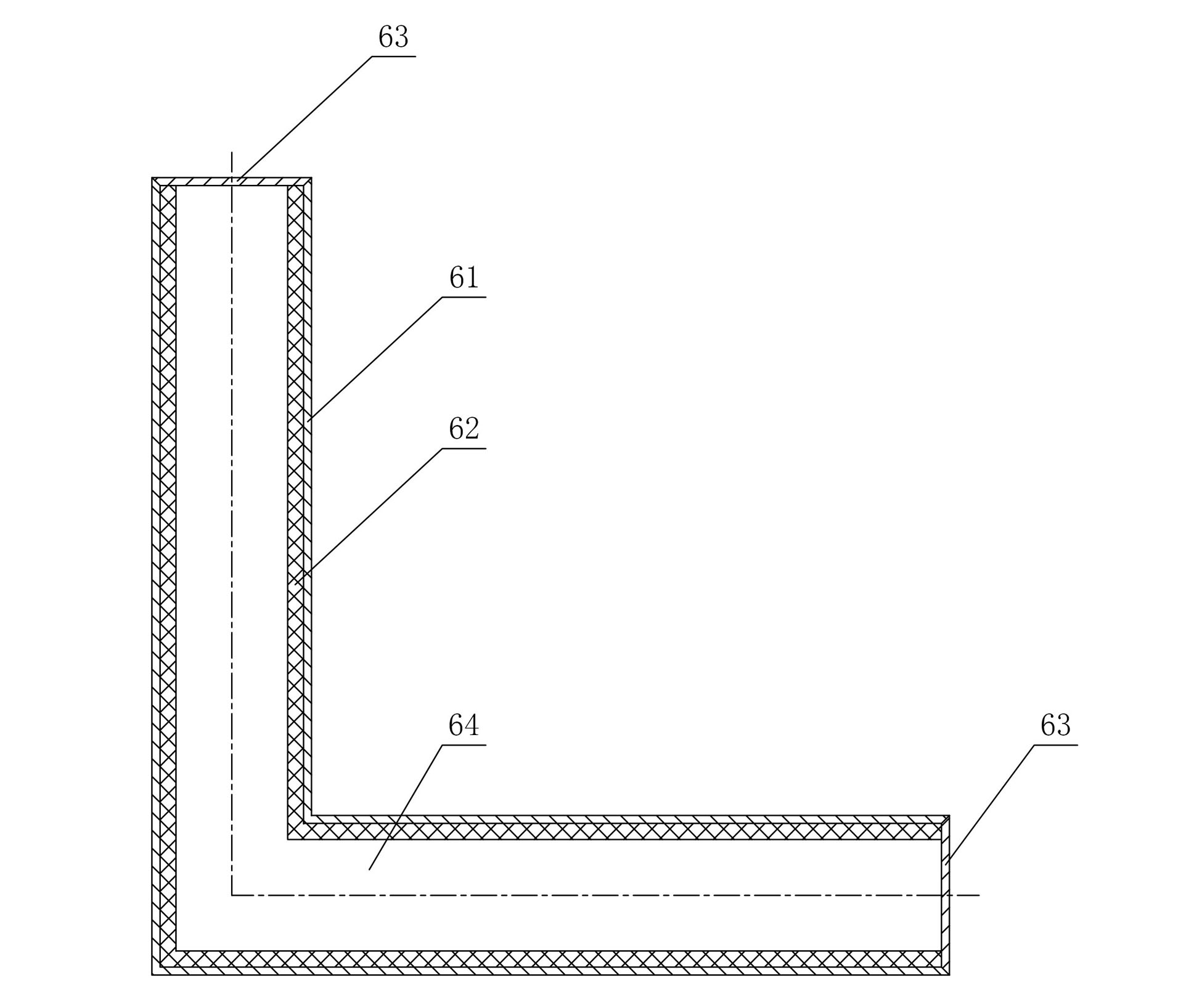

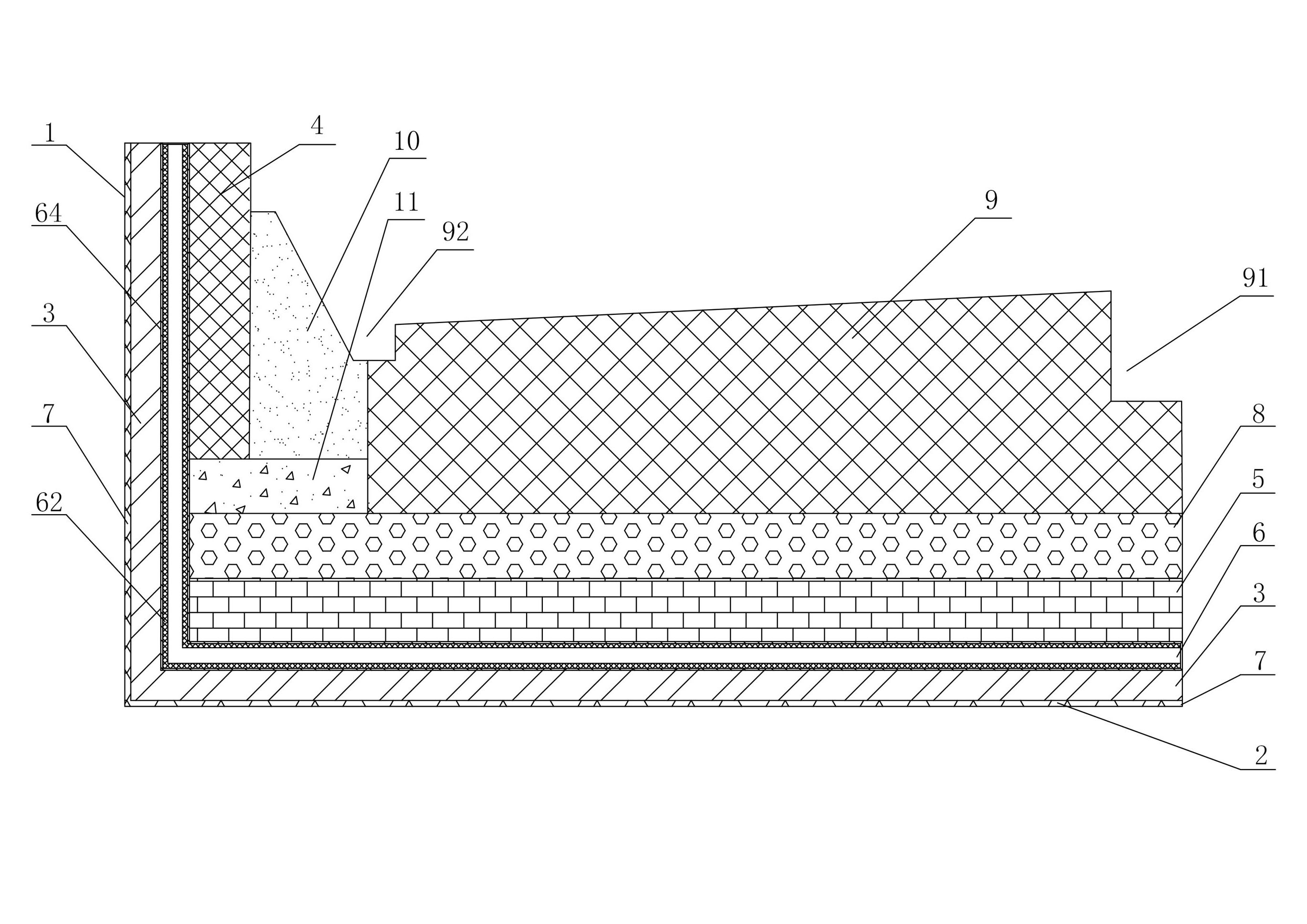

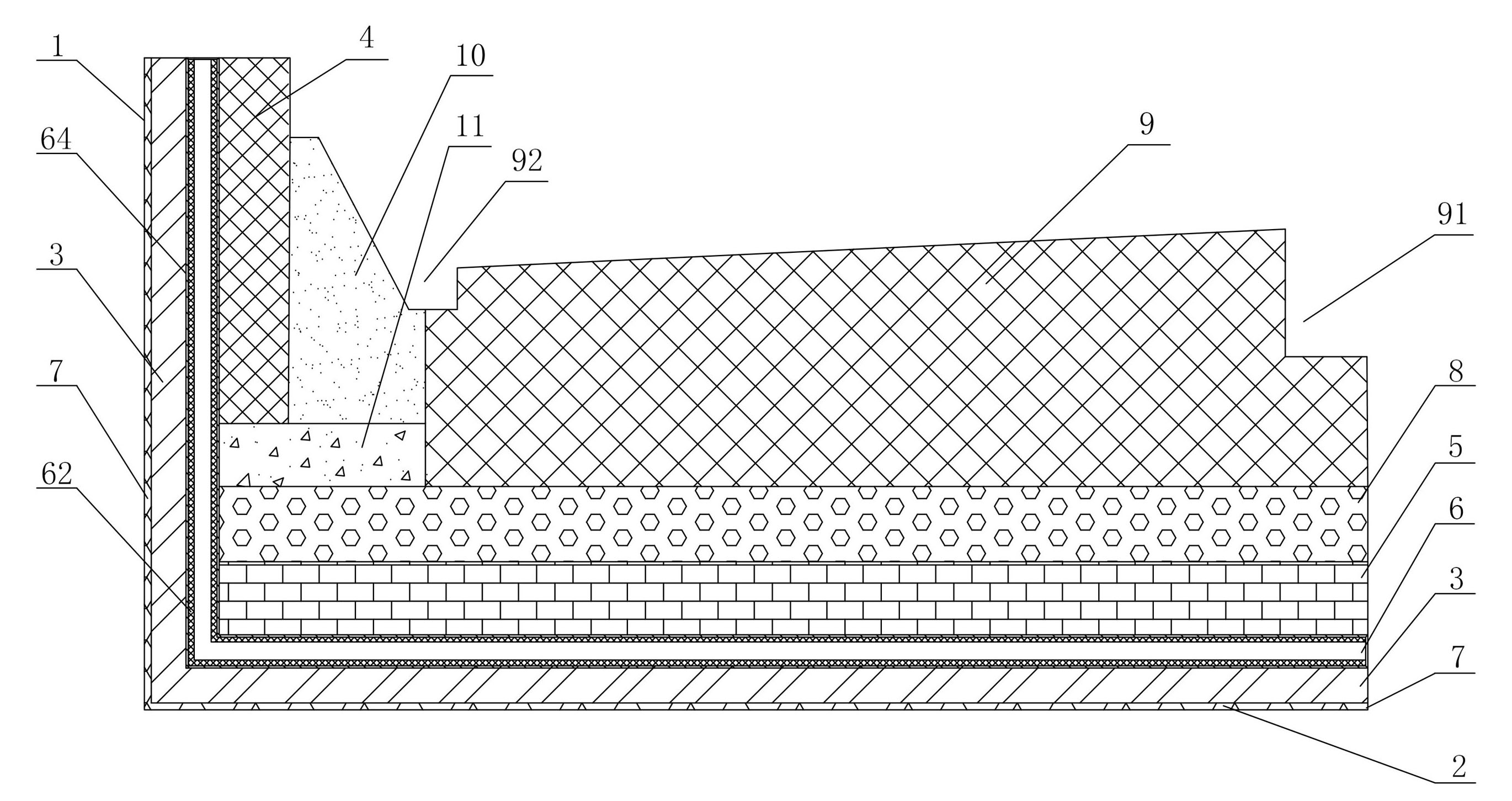

[0019] figure 1 A heat pipe embodiment of the present invention is shown, the heat pipe includes a tube shell 61, a liquid-absorbing core 62 and a sealing end cap 63, the tube shell 61 is L-shaped, and the liquid-absorbing core 62 is covered on the inner wall of the tube shell 61, The sealing end caps 63 are mounted on both ends of the tube shell 61 to form a closed lumen 64, and the sealed lumen 64 is filled with working fluid. The heat pipe of the present invention is simple in structure, easy to manufacture, and low in cost. The L-shaped shell 61 is convenient to be installed in the aluminum electrolytic cell, and transfers the heat from the side of the aluminum electrolytic cell to the bottom; The working liquid is absorbed by the liquid-absorbing core 62 and sent to the evaporating section, where the working liquid absorbs heat and turns into a gas, and then returns to the condensation section through the sealed lumen 64 to release heat and turn back into a liquid. This c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com