Laser module

A laser module and laser diode technology, which is applied to light sources, electric light sources, point light sources, etc., can solve the problems of inability to effectively detect the temperature of laser diodes and discounts on the use efficiency of laser modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

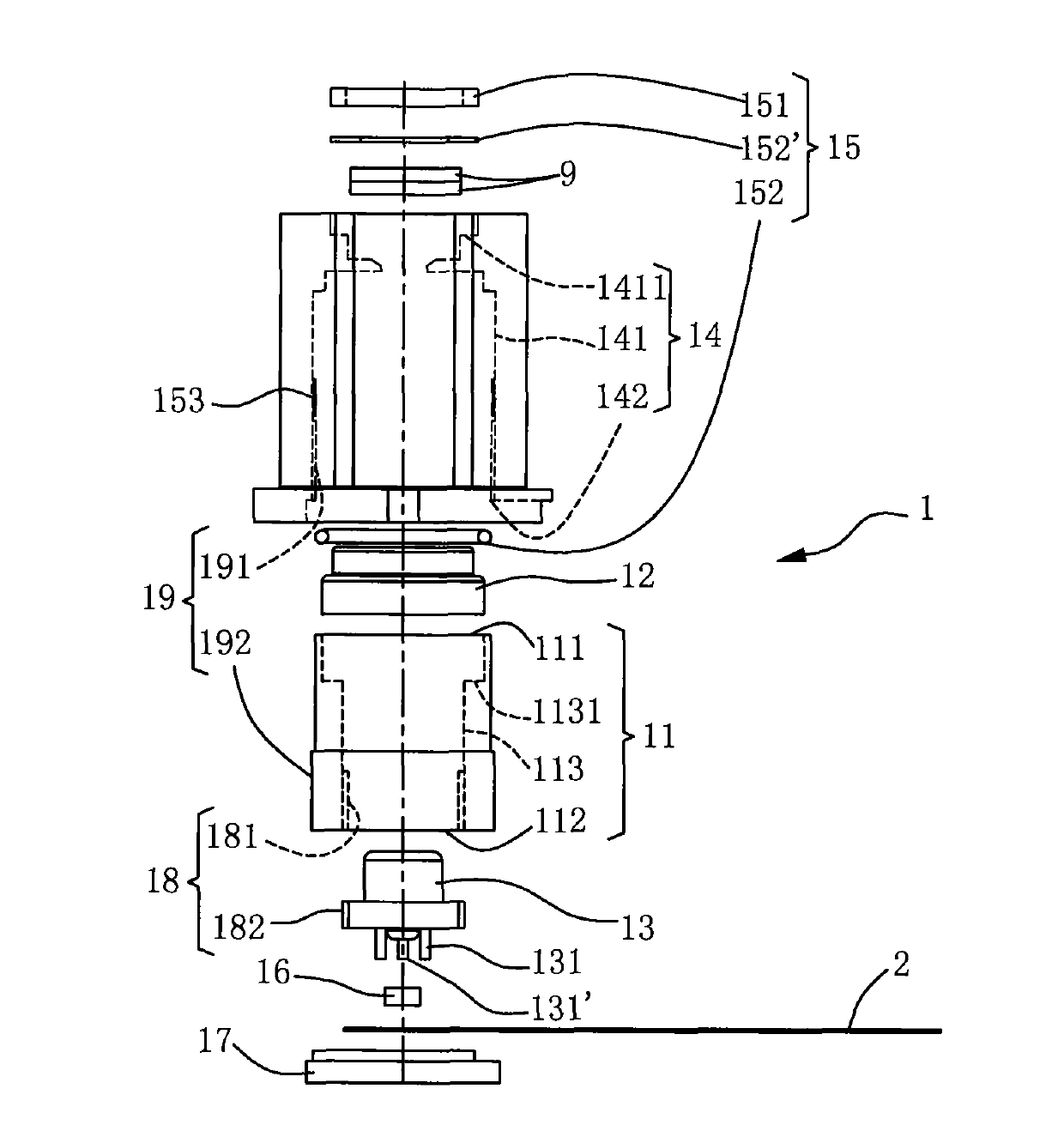

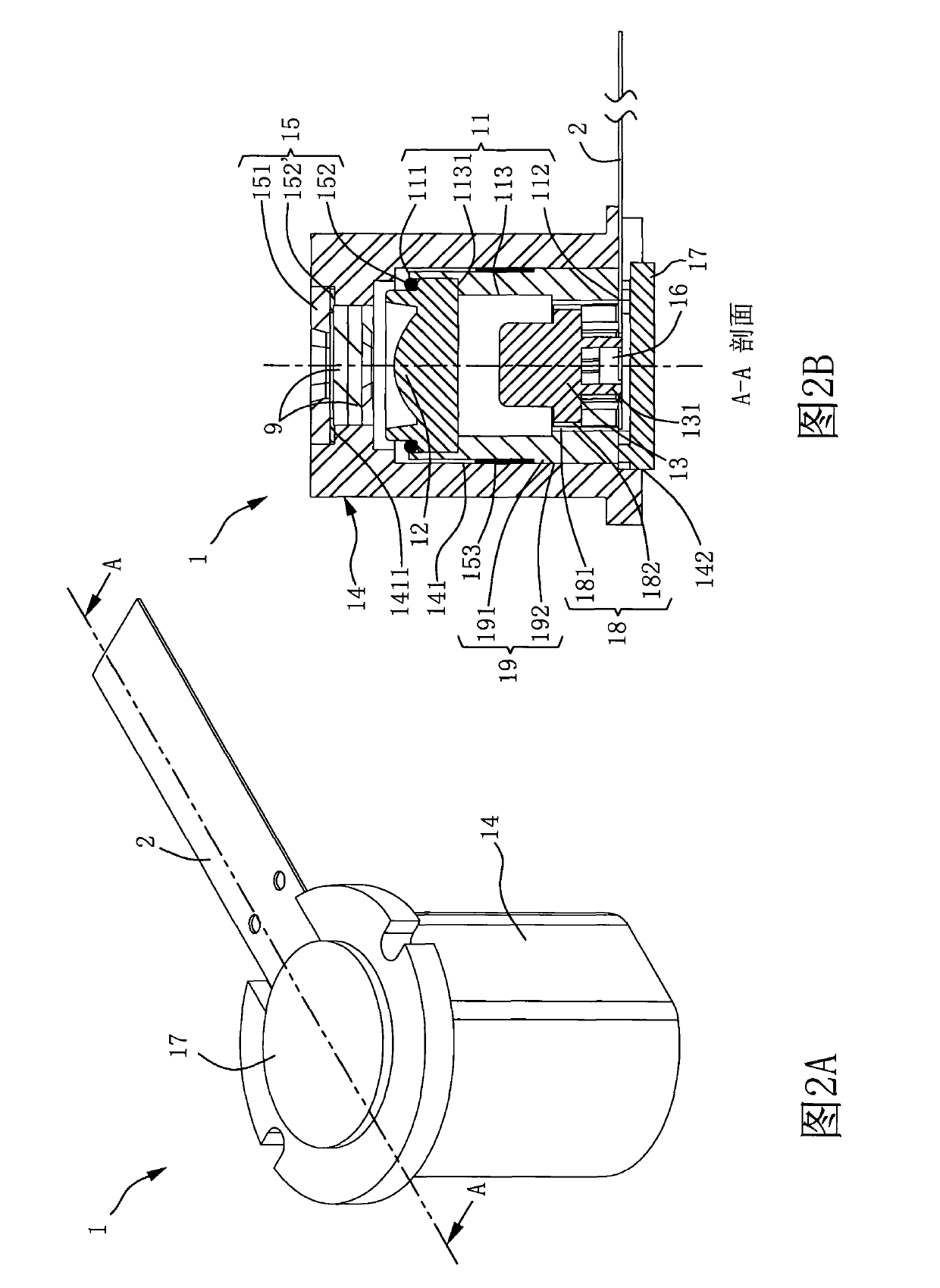

[0039] In order to describe the laser module proposed by the present invention more clearly, it will be described in detail below with reference to the drawings.

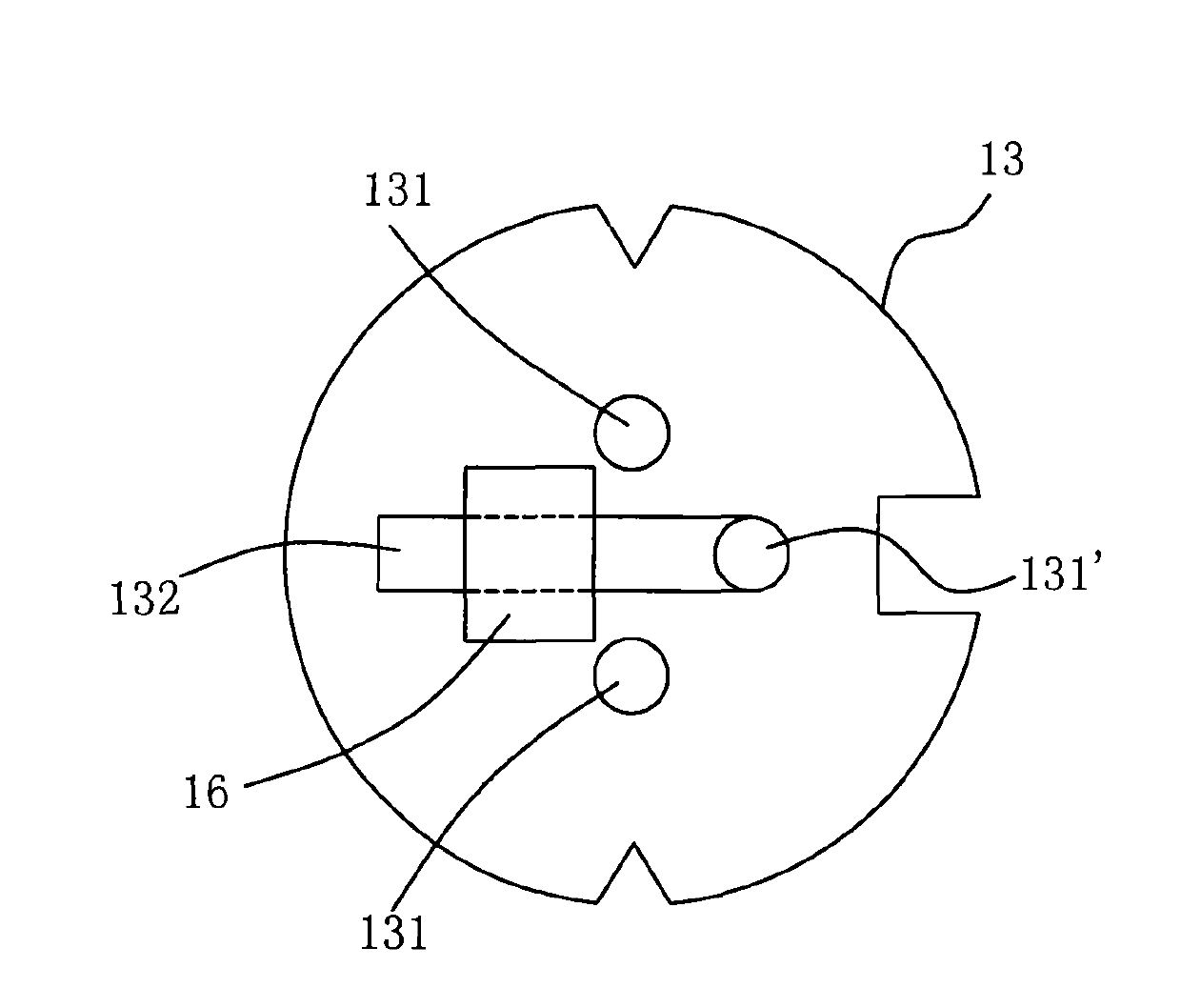

[0040] see figure 1 , Figure 2A , Figure 2B , Figure 2C As shown, wherein, the laser module 1 is connected to a circuit board 2, which includes: a cylindrical body 11, a focusing lens 12, a laser diode 13, a housing 14, an airtight structure 15, a temperature The sensing element 16 , a temperature control board 17 , and an image lens 9 . The main body 11 further includes: a front open end 111 , a rear open end 112 , and an inner wall 113 . A concave step 1131 is formed on the inner wall 113 adjacent to the front opening 111 . The airtight structure 15 is used to prevent outside moisture from intruding into the laser module 1, thereby affecting the projection effect of the image lens 9, and it further includes: a pressure ring 151, a plurality of sealing rubber rings 152, And a seal glue 153. In the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com