Device and method for generating silicon nitride film

A technology of silicon nitride film and generation device, which is applied in gaseous chemical plating, metal material coating process, coating, etc. Guaranteed build quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

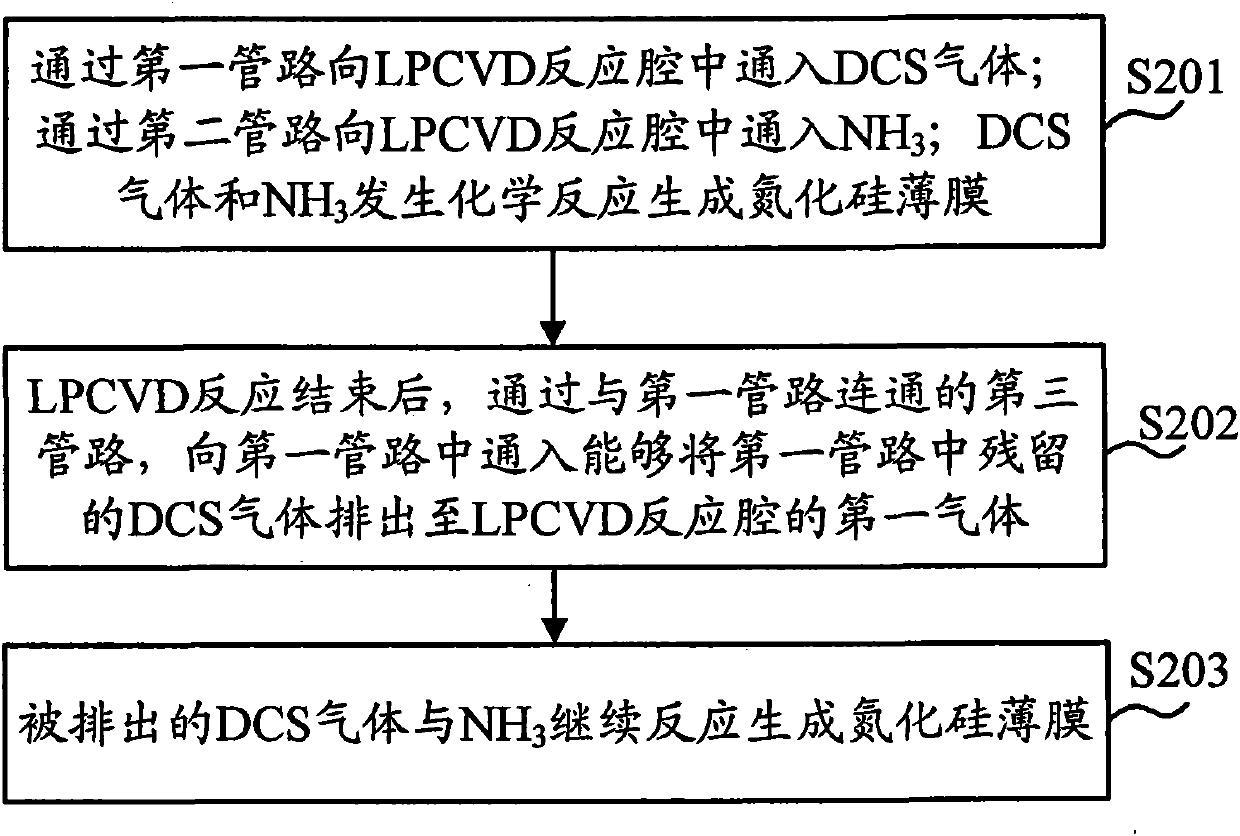

[0017] The specific implementation of a silicon nitride film forming device and method provided by the present invention will be described in detail below with reference to the accompanying drawings.

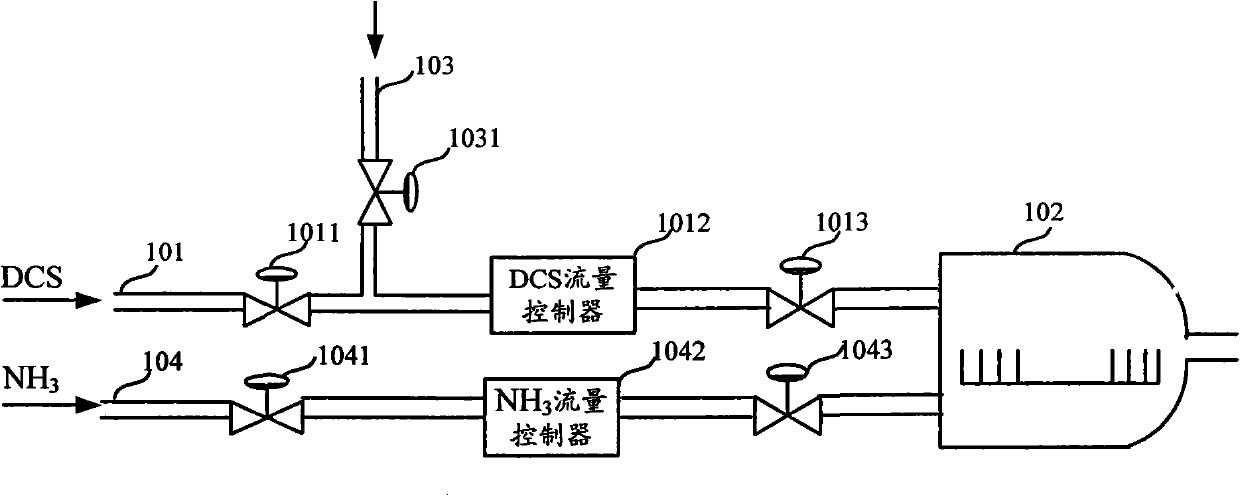

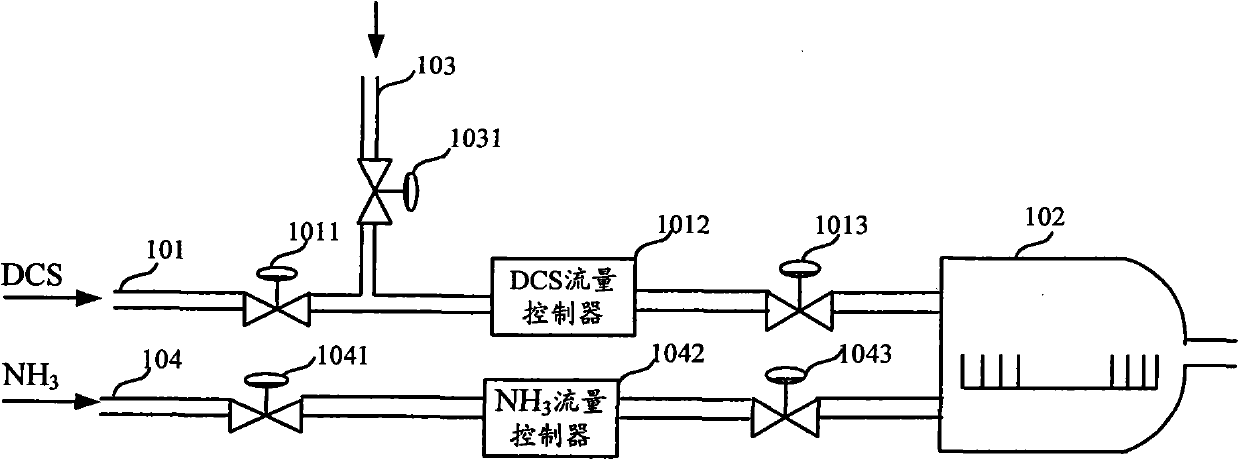

[0018] A device for forming a silicon nitride film provided by an embodiment of the present invention includes: a first pipeline for feeding DCS gas, a first pipeline for feeding NH 3 The second pipeline, the third pipeline and the LPCVD reaction chamber; wherein:

[0019] The outer surface of the first pipeline is wrapped with a heating tape, and the first pipeline and the second pipeline are respectively connected to the LPCVD reaction chamber;

[0020] The third pipeline communicates with the first pipeline, and is used to discharge the DCS gas remaining in the first pipeline into the first pipeline after stopping the introduction of DCS gas into the LPCVD reaction chamber. The first gas of the LPCVD reaction chamber.

[0021] A specific example is used below to illustrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com