Oxidizing roasting process by blending high fluorine chlorine zinc oxide complex material

A high-fluorine chloride zinc oxide and oxidation roasting technology, which is applied in the field of oxidation roasting technology mixed with high-fluorine chloride zinc oxide miscellaneous materials, can solve the problems of low roasting intensity and high smoke and dust rate in fluidized fluidized furnaces, and achieve improved roasting intensity and production efficiency , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

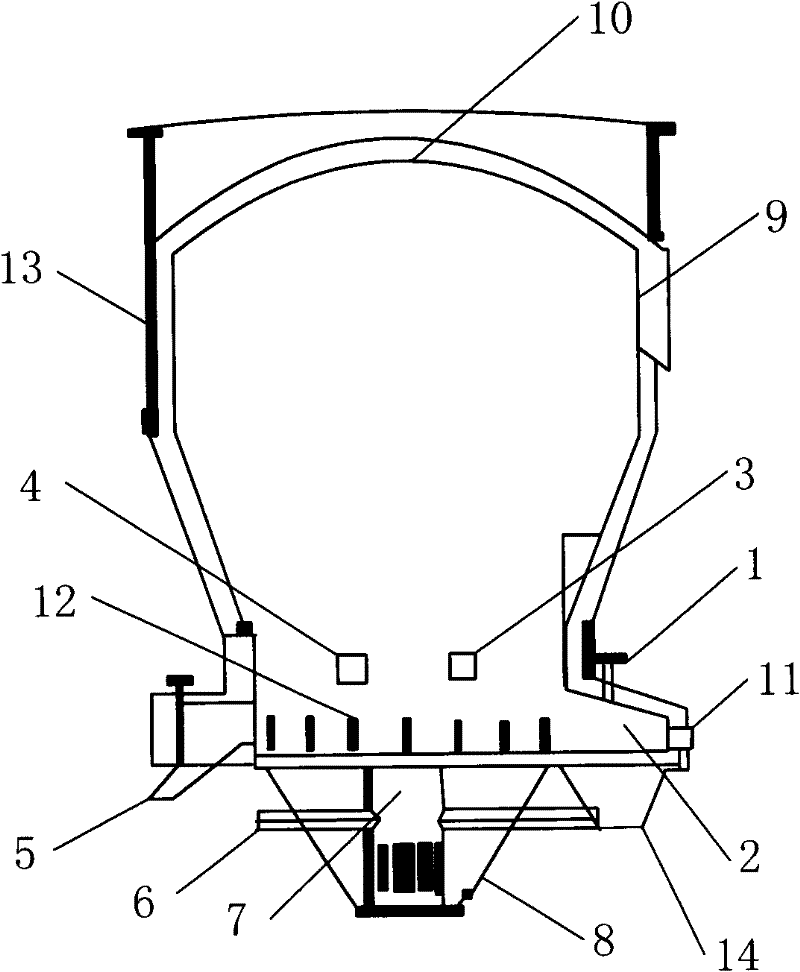

Image

Examples

Embodiment 1

[0047]Ingredients: select zinc concentrate composition: Zn≥47%, Pb2 2 O<10%, As+Sb<0.45%.

[0048] The mixed high-fluorine chlorine zinc oxide miscellaneous material is steelmaking rotary hearth furnace dust, composition: Zn50%, Pb8.8%, Fe6.0%, S2.34%, SiO 2 0.69%, F0.35% and Cl3.8%, the blending amount is 7-10% of the zinc concentrate by mass percentage.

[0049] The composition of the mixture is: Zn47.19~47.27%, Pb1.51~1.71%, Fe9.64~9.74%, S27.5~28%, SiO 2 5.97-6.12%, F0.023-0.032%, C10.25-0.35%.

[0050] Roasting: It is added to the fluidized furnace through a disc feeder. The reaction process does not require additional heating, and the heat is provided by the heat released by the reaction of sulfide and oxygen. After high-temperature oxidation roasting in fluidized bed furnace, in addition to the normal removal of lead, cadmium and sulfur, zinc-containing miscellaneous materials are also processed to remove fluorine and chlorine. The total soot output rate is 15-16%, t...

Embodiment 2

[0052] Ingredients: select zinc concentrate Composition: Zn≥47%, Pb2 2 O<10%, As+Sb<0.45%.

[0053] The mixed high-fluorine chlorine zinc oxide miscellaneous material is steelmaking electric furnace dust, composition: Zn48.8%, Pb1.32%, Fe1.54%, S1%, SiO 2 1.86%, F0.57% and C13.21%, the blending amount is 7.4-9.4% of the mixture by mass percentage.

[0054] The composition of the mixture is: Zn 47.12-47.15%, Pb1.02-1.03%, Fe9.27-9.42%, S27.5-28%, SiO 2 6.1-6.18%, F0.039-0.049%, C10.22-0.28%.

[0055] Roasting process is as embodiment 1.

[0056] Effect: The total dust output rate is 15-16%, the electric dust output rate is 1%, and the baked sand contains 0.050% chlorine and 0.020% fluorine.

Embodiment 3

[0058] Ingredients: select zinc concentrate Composition: Zn≥47%, Pb2 2 O<10% and As+Sb<0.45%.

[0059] The mixed high-fluorine chlorine zinc oxide miscellaneous material is regenerated copper recovery dust, composition: Zn49.35%, Pb0.44%, Fe1.22%, S1%, F0.36% and C13.42%, blending amount 7.4-9.4% by mass percentage.

[0060] The composition of the mixture is: Zn47.16~47.20%, Pb0.95~0.96%, Fe9.25~9.40%, S27.5~28%, SiO 2 5.94-6.1%, F0.025-0.031%, C10.24-0.29%.

[0061] Roasting process is as embodiment 1.

[0062] Effect: The total dust output rate is 15-16%, the electric dust output rate is 1%, and the baked sand contains 0.050% chlorine and 0.020% fluorine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com