Method for preparing superfine calcium carbonate compound particles

A technology of ultra-fine calcium carbonate and composite particles, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of affecting the coating effect and falling off, and achieve low cost, prevent agglomeration, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

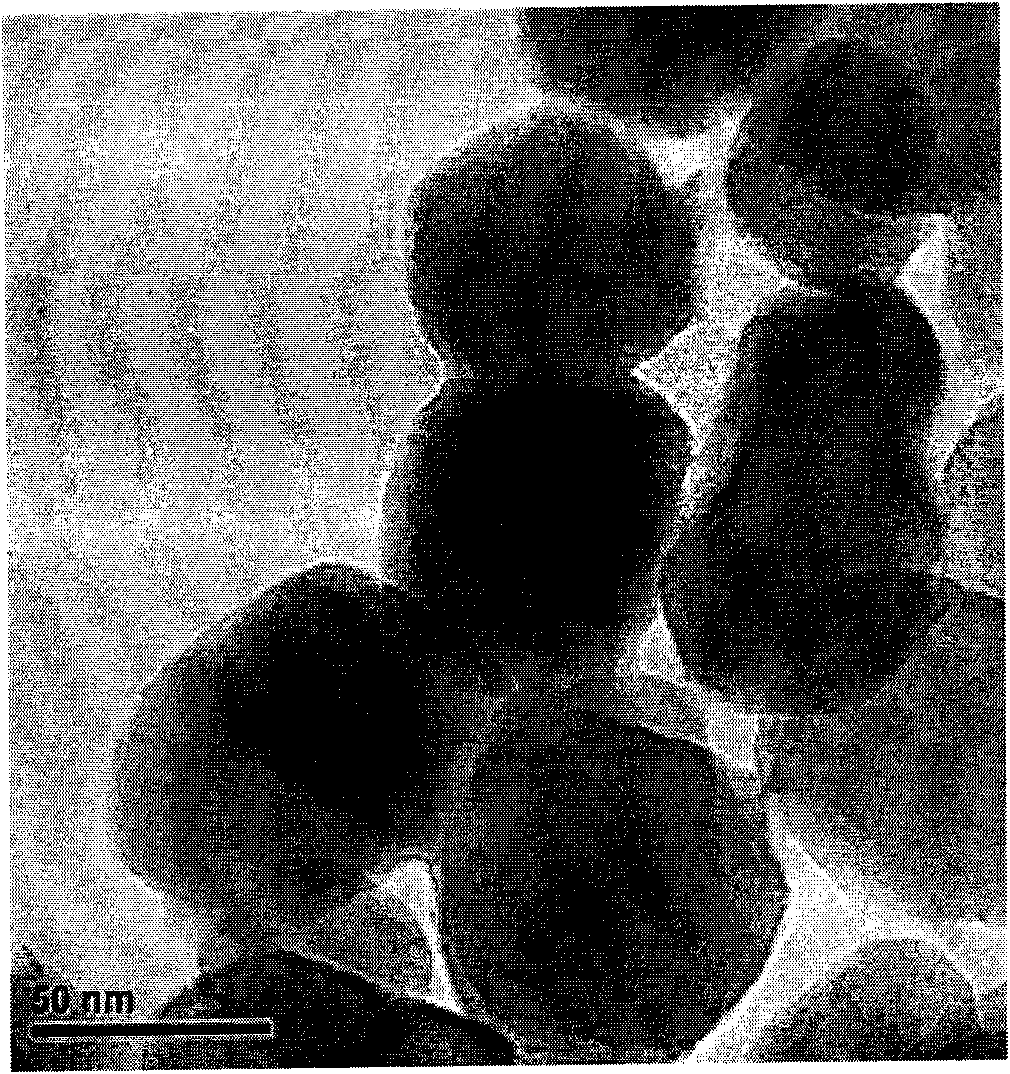

Image

Examples

Embodiment 1

[0033] Add 5 liters of refined lime milk suspensions with a concentration of 10% (weight concentration) and an initial temperature of 30°C in a 7-liter stirred reactor, add 20 g of sucrose and 13.75 g of triethanolamine at the same time, and feed the carbon dioxide content after stirring evenly. The kiln gas with 30% (volume concentration) starts carbonization reaction, and the kiln gas flow rate is 150 L / h. When the pH value of the carbonization reaction system was at 8.5, the aqueous solution of water glass with a modulus of 3.1 was added to the system. The total amount of water glass added was 142.63g, and the pH value of the control system was 9.5. After the water glass was added completely , stop feeding carbon dioxide gas, and let the reaction system age at 60°C for 2 hours, and then feed carbon dioxide gas. When the pH value of the system is 6.5, the reaction is completed, and the obtained slurry is filtered, washed, and dried to obtain cubic and similar Spherical ultra...

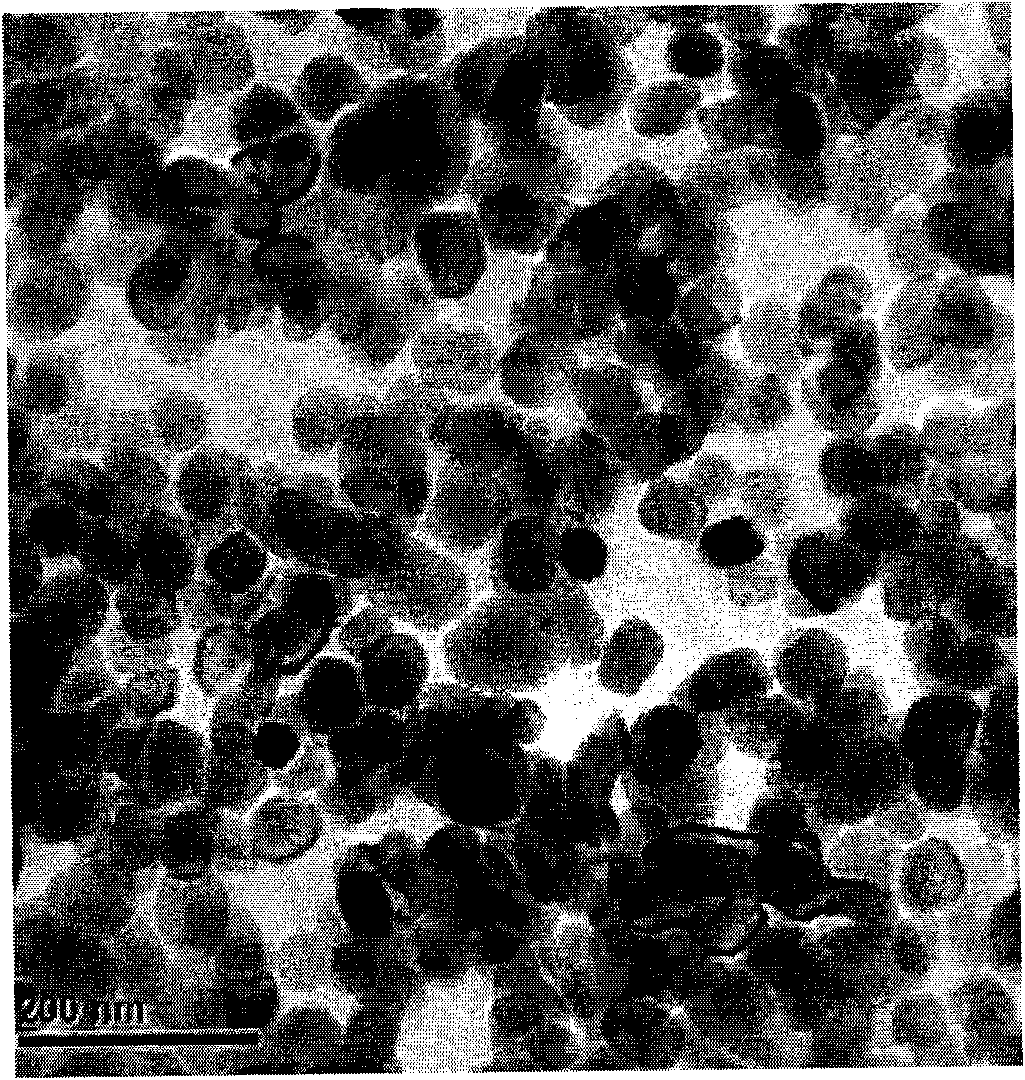

Embodiment 2

[0036]Adding 5 liters of concentration is 15% (weight concentration) initial temperature in the stirred reactor of 7 liters and is the refining lime milk suspension of 25 ℃, adds 6g sodium citrate simultaneously, after stirring, pass into carbon dioxide content and be 40 % (volume concentration) gas starts to undergo carbonization reaction, and the gas flow rate is 80L / h. When the pH value of the carbonization reaction system was at 7.0, adding 120.2g modulus to the system was the solution of water glass of 3.1, and the pH value of the control system was 9.0, after the water glass was added completely, stop feeding carbon dioxide gas, and Let the reaction system age at 50°C for 2.5 hours, and then pass in carbon dioxide gas. After the pH of the system is 6.5, the reaction is completed, and the obtained slurry is filtered, washed, and dried to obtain ultrafine calcium carbonate composite particles coated with silicon dioxide. .

[0037] The average particle size measured by el...

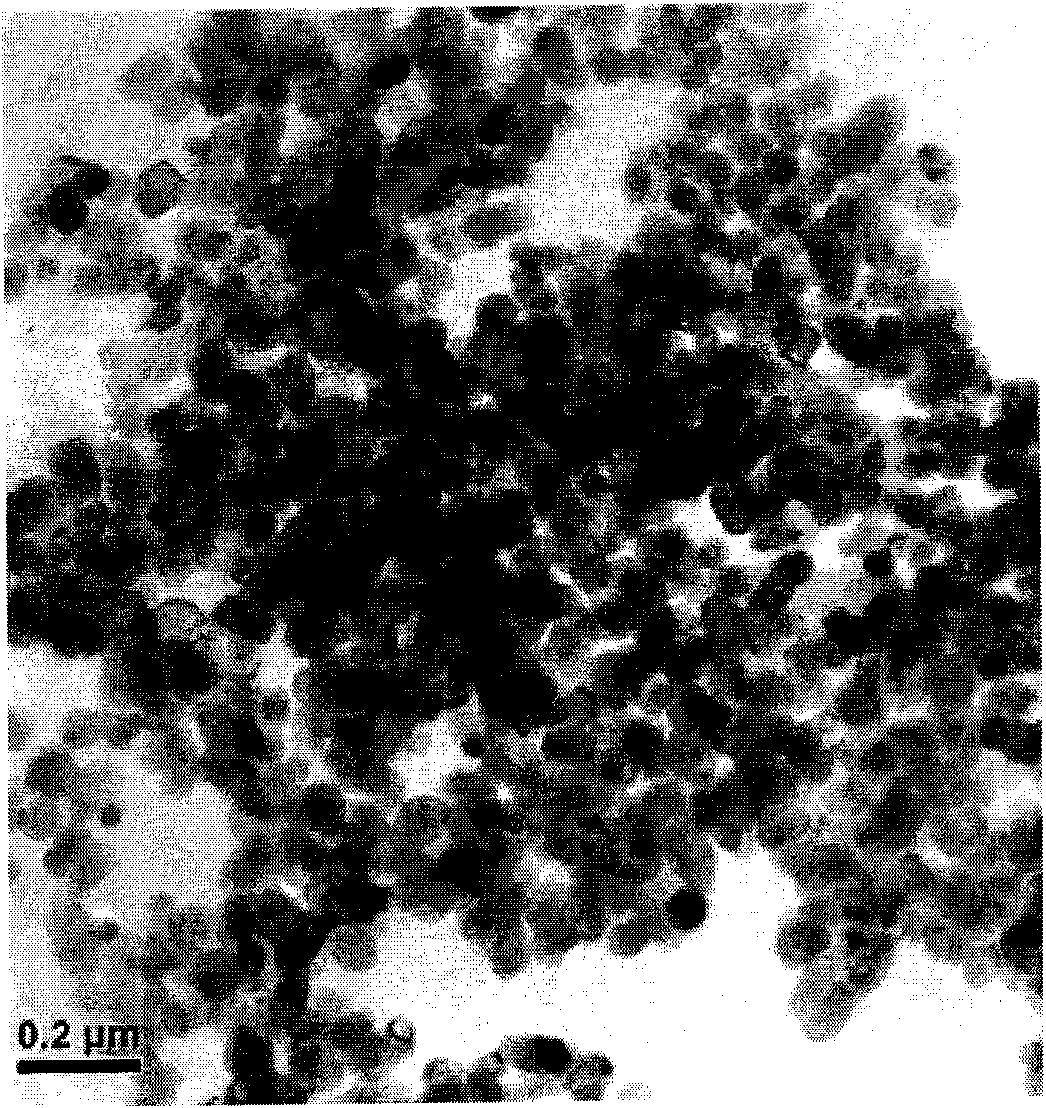

Embodiment 3

[0039] Adding 5 liters of concentrations in the stirred reactor of 7 liters is that the initial temperature of 13% (weight concentration) is the refining lime milk suspension and 8g sodium citrate at 30°C, and after stirring, it is 25% (volume) to feed carbon dioxide content Concentration) kiln gas starts carbonization reaction, and the flow rate of kiln gas is 100L / h. When the pH value of the carbonization reaction system was at 8.0, 317.9 g of 30 wt % potassium metasilicate aqueous solution was added to the system, and the pH value of the control system was 7.5. After the potassium silicate aqueous solution was added completely, stop feeding carbon dioxide gas, And let the reaction system age at 80°C for 3 hours, and then pass in carbon dioxide gas. After the pH value of the system is 6.5, the reaction is completed, and the obtained slurry is filtered, washed, and dried to obtain a silica-coated ultrafine calcium carbonate compound particles.

[0040] The average particle s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com