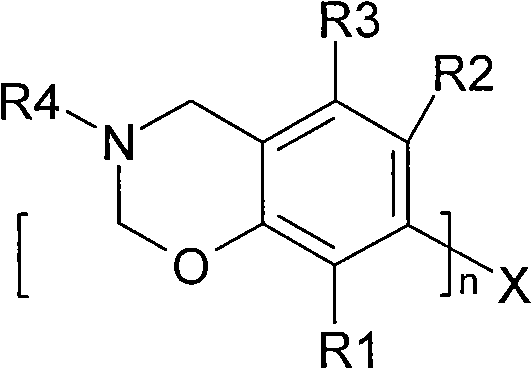

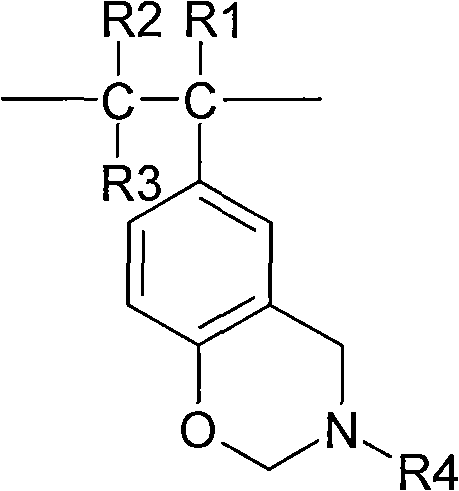

Furfurylamine type benzoxazine resin/maleimide compound composition

A technology of maleimide and benzoxazine, applied in the field of furfurylamine type benzoxazine resin/maleimide compound composition, can solve problems such as lowering curing temperature, achieve low porosity, shrinkage small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Configure octamaleimidized POSS (OMPS) and bisphenol A furfurylamine type benzoxazine resin composition with a ratio (mass ratio) of 0.5:99.5. The composition is tested by DSC, and the curing peak temperature is measured to be 231 ℃.

Embodiment 2

[0052] Configure octamaleimidized POSS (OMPS) and bisphenol A furfurylamine type benzoxazine resin composition with a ratio (mass ratio) of 1:99, and the composition is subjected to DSC test, and the curing peak temperature is measured to be 230 ℃.

Embodiment 3

[0054] Configure octamaleimidized POSS (OMPS) and bisphenol A furfurylamine type benzoxazine resin composition with a ratio (mass ratio) of 2:98, and the composition is subjected to DSC test, and the curing peak temperature is measured to be 226 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com