Method for treating collophanite positive and reverse flotation beneficiation wastewater

A technology of positive and negative flotation and beneficiation wastewater, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Removing, not considering industrial recycling and other issues, to achieve the effect of cost saving, cost reduction, and damage avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, treatment of high hardness wastewater produced by collophosite forward and reverse flotation

[0019] according to figure 1 The process flow diagram shown treats the wastewater.

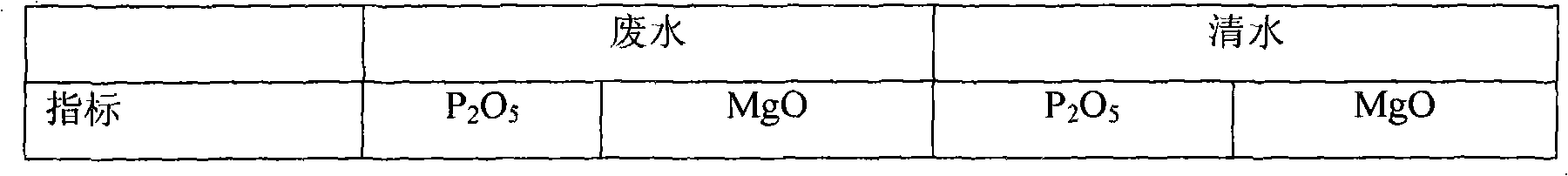

[0020] The water quality indicators of the high hardness wastewater produced by collophosite forward and reverse flotation before treatment are as follows: Ca 2+ 86.33mg / L, Mg 2+ 78.24mg / L, PO 4 3- 98.51mg / L, SO 4 2- 826.7mg / L, pH value 7.8, total hardness 609.3mg / L.

[0021] (1) According to the molar ratio of the magnesium content in the clean lime and the waste water=1.2:1; the calcium content in the soda ash and the waste water (comprising the calcium ions brought by the clean lime, 1.05 times of the soda ash can remove the calcium ions in the raw water, plus 0.2 times the amount of soda ash to remove the calcium ions brought in by the refined lime) ratio = 1.25: 1 ratio to prepare a certain concentration of refined lime emulsion and soda ash solution in 1# and 2# dosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com