Multifunctional angle pin discharging fixture

A multi-functional, oblique pin technology, applied in the direction of manufacturing tools, electric processing equipment, clamping, etc., can solve the problems of costly processing steps, slow processing speed, and cumbersome, etc., and achieve the effect of improving and simplifying processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

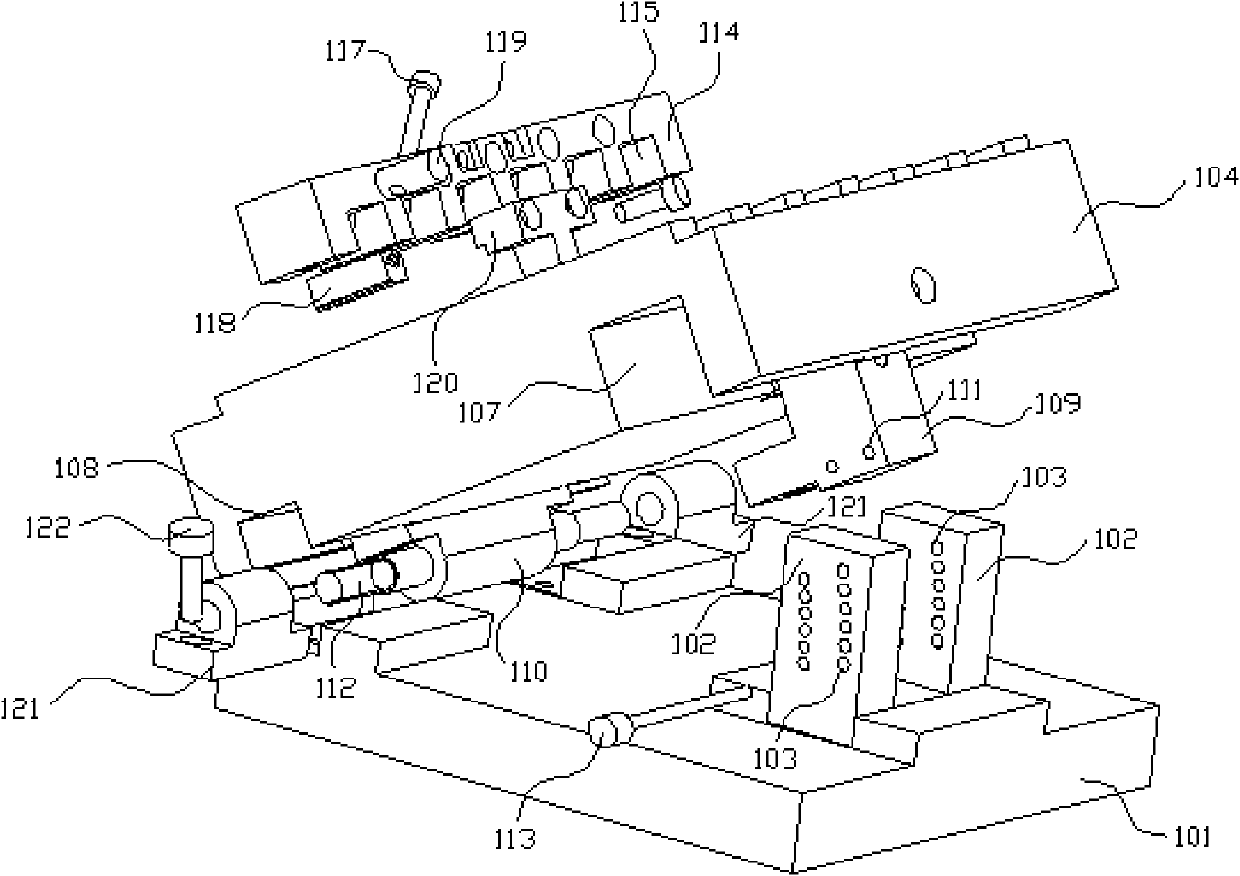

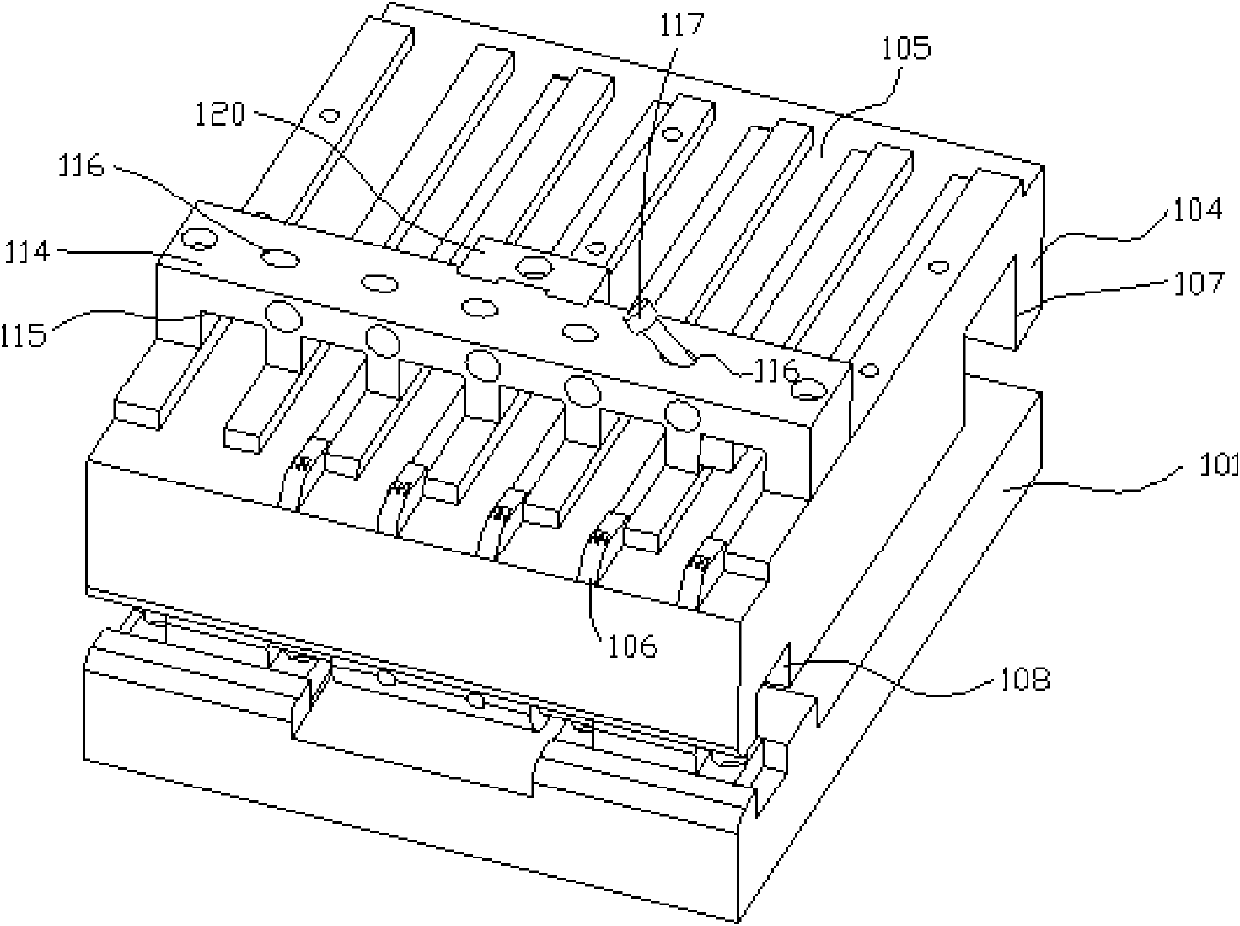

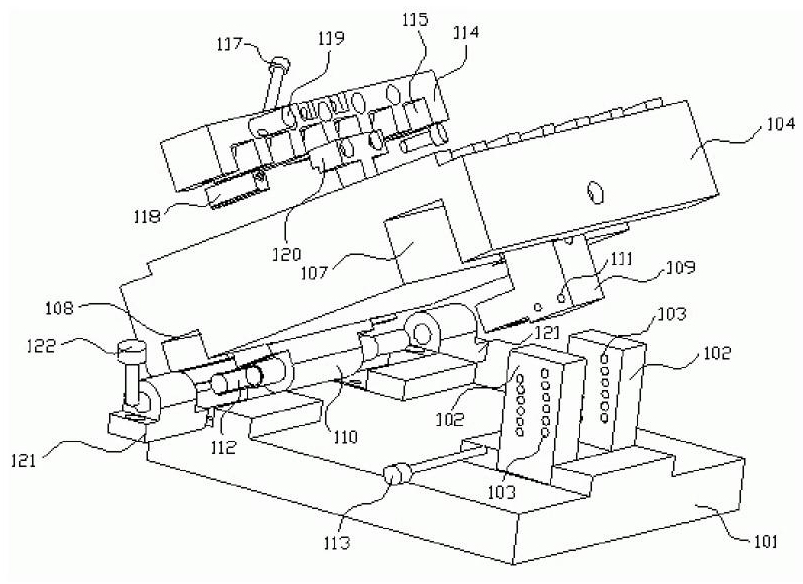

[0015] In order to illustrate the technical content and structural features of the present invention in detail, the following will be described in detail in conjunction with the implementation and accompanying drawings.

[0016] see figure 1 with figure 2 , is a schematic exploded view and an assembled schematic view of the multi-functional oblique pin discharge fixture of the present invention. The end face of the base 101 is provided with two protruding lower angle adjustment blocks 102, the size and shape of the two lower angle adjustment blocks 102 are consistent, and the positions are on the same straight line. The through angle adjustment hole 103, the angle adjustment hole 103 is arranged in a circular arc shape on the sides of the two lower angle adjustment blocks 102, the positions of the angle adjustment holes 103 of the two lower angle adjustment blocks 102 correspond to each other, the two lower angle adjustment There is a gap between the 102 blocks.

[0017] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com