Modified Y molecular sieve-containing catalytic cracking catalyst

A cracking catalyst and catalytic cracking technology, applied in molecular sieve catalyst, catalytic cracking, physical/chemical process catalyst, etc., can solve the problems of high activity and good coke selectivity, low utilization rate of rare earth, complex modification process, etc. Good coke selectivity, improved heavy oil conversion capacity, optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

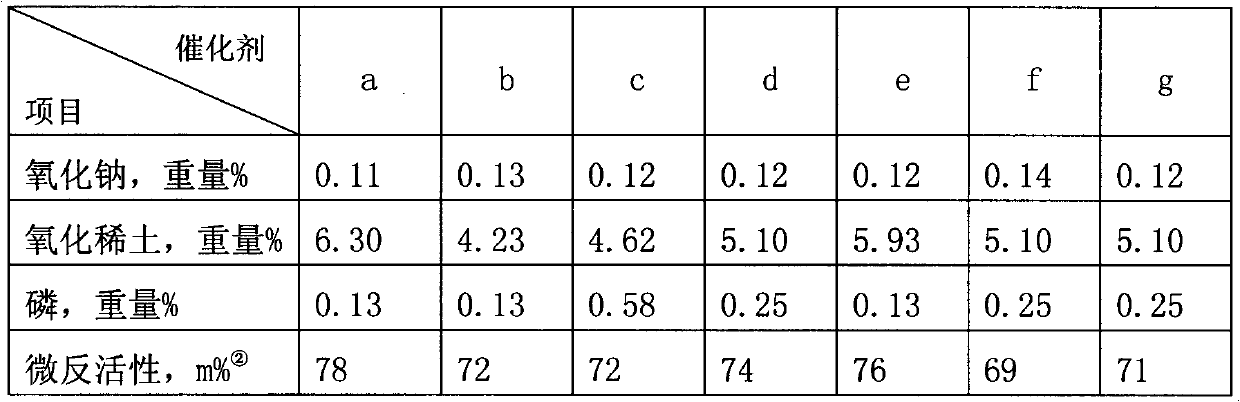

Examples

Embodiment 1

[0029] Take 5 kg of NaY (dry basis), add 50 liters of deionized water, make a slurry, slowly add 5 liters of rare earth chloride solution under stirring, use 3 mol / liter of hydrochloric acid to adjust the slurry pH to 4.5, exchange at 30 ° C for 0.5 hours, Then add 83.3 grams of diammonium hydrogen phosphate, continue to react for 1 hour, filter and wash with water, and filter cake is roasted for 1.5 hours at 500° C. under 80% water vapor condition to obtain the modified Y subsieve of the present invention. for P-1.

[0030] With 1.75 kilograms of kaolin (dry basis), use the above-mentioned method to make modified Y molecular sieve P-12.77 kilograms, 1 kilogram of pseudo-boehmite (63.2 weight % of alumina content, the same below), 2 kilograms of aluminum sol and 6 kilograms of deionized Mix with water, stir and add 160 ml of hydrochloric acid, stir for 1 hour, spray dry, wash and dry to obtain catalyst a.

Embodiment 2

[0032]Take 5 kg of NaY (dry basis), add 40 liters of deionized water, make a slurry, slowly add 3.2 liters of rare earth chloride solution under stirring, use 2 mol / liter of hydrochloric acid to adjust the slurry pH to 5.5, exchange at 40 ° C for 50 minutes, Then add 83.3 grams of diammonium hydrogen phosphate, continue to react for 0.5 hour, filter, wash with water, filter cake is at 550 ℃, roasting 1 hour under 100% water vapor condition, obtain " one cross one roasting " modified Y subsieve of the present invention, record for P-2.

[0033] The catalyst was prepared under the same conditions as in Example 1, except that the modified Y molecular sieve P-1 was changed to the modified Y molecular sieve P-2, and 0.1 kg of ZSM-5 was added. Kaolin is changed to halloysite, and the addition amount remains unchanged to obtain catalyst b of the present invention.

Embodiment 3

[0035] Take 5 kilograms of NaY (dry basis), add 25 liters of deionized water, make a slurry, slowly add 5.0 liters of rare earth nitrate solution under stirring, use 2 mol / liter of hydrochloric acid to adjust the slurry pH to 6.0, exchange for 2 hours at 20 ° C, and then Add 416.5 grams of ammonium dihydrogen phosphate, continue the reaction for 1 hour, filter, wash with water, and roast the filter cake for 3 hours at 350° C. under 100% water vapor conditions to obtain the modified Y subsieve of the present invention, denoted as P-3.

[0036] With 1.75 kilograms of kaolin (dry basis), 1.25 kilograms of modified Y molecular sieve P-3, 0.2 kilograms of β molecular sieves, 1.9 kilograms of pseudoboehmite, 2.49 kilograms of aluminum sol and 6 kilograms of deionized water were mixed and stirred After that, 190 ml of hydrochloric acid was added, stirred for 1 hour, spray-dried, washed and dried to obtain catalyst c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com