Method for designing automobile body structure layout

A technology of structural layout and design method, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of long development time, poor accuracy, and inability to obtain the comparison results of various layout plan data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

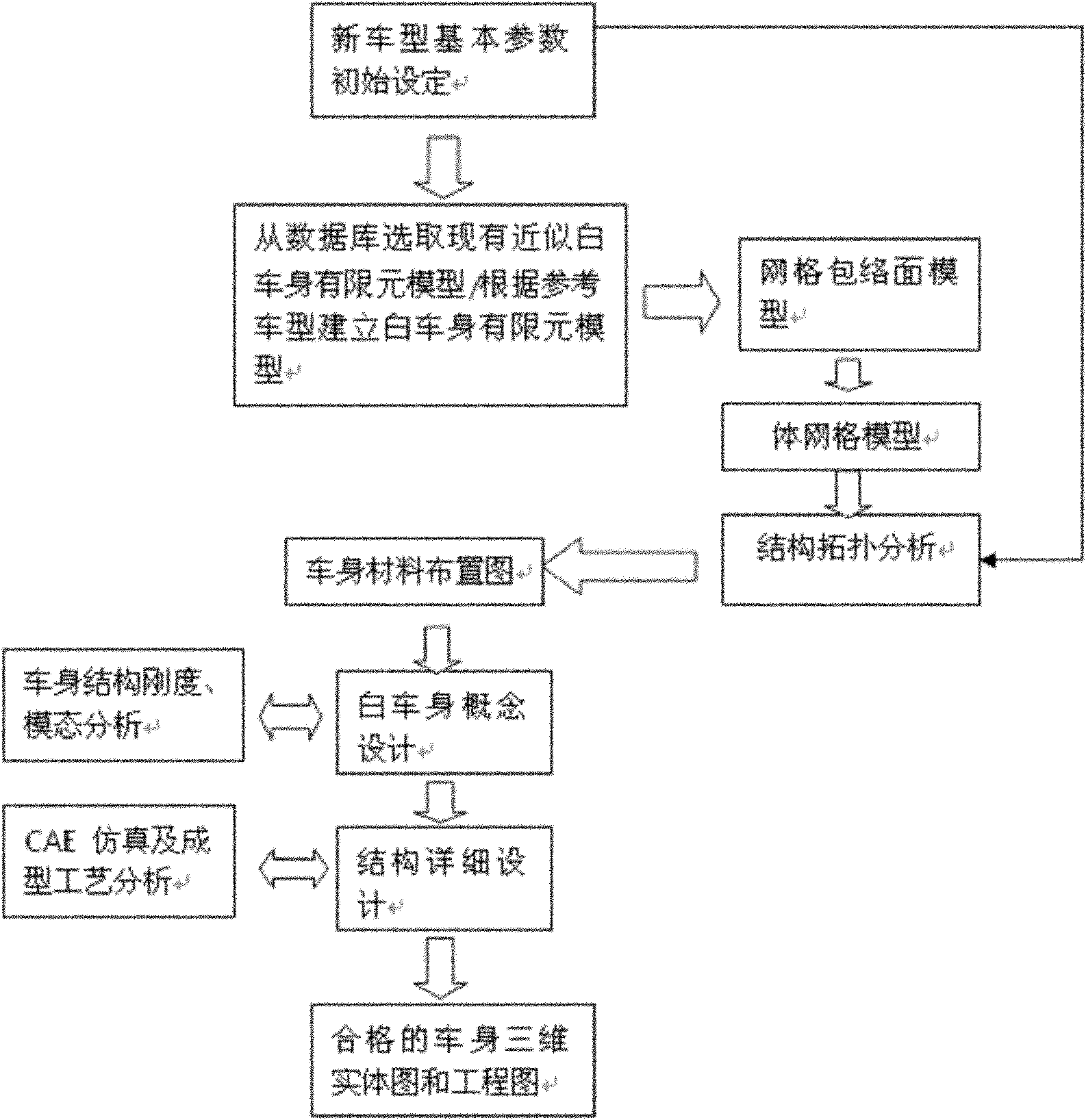

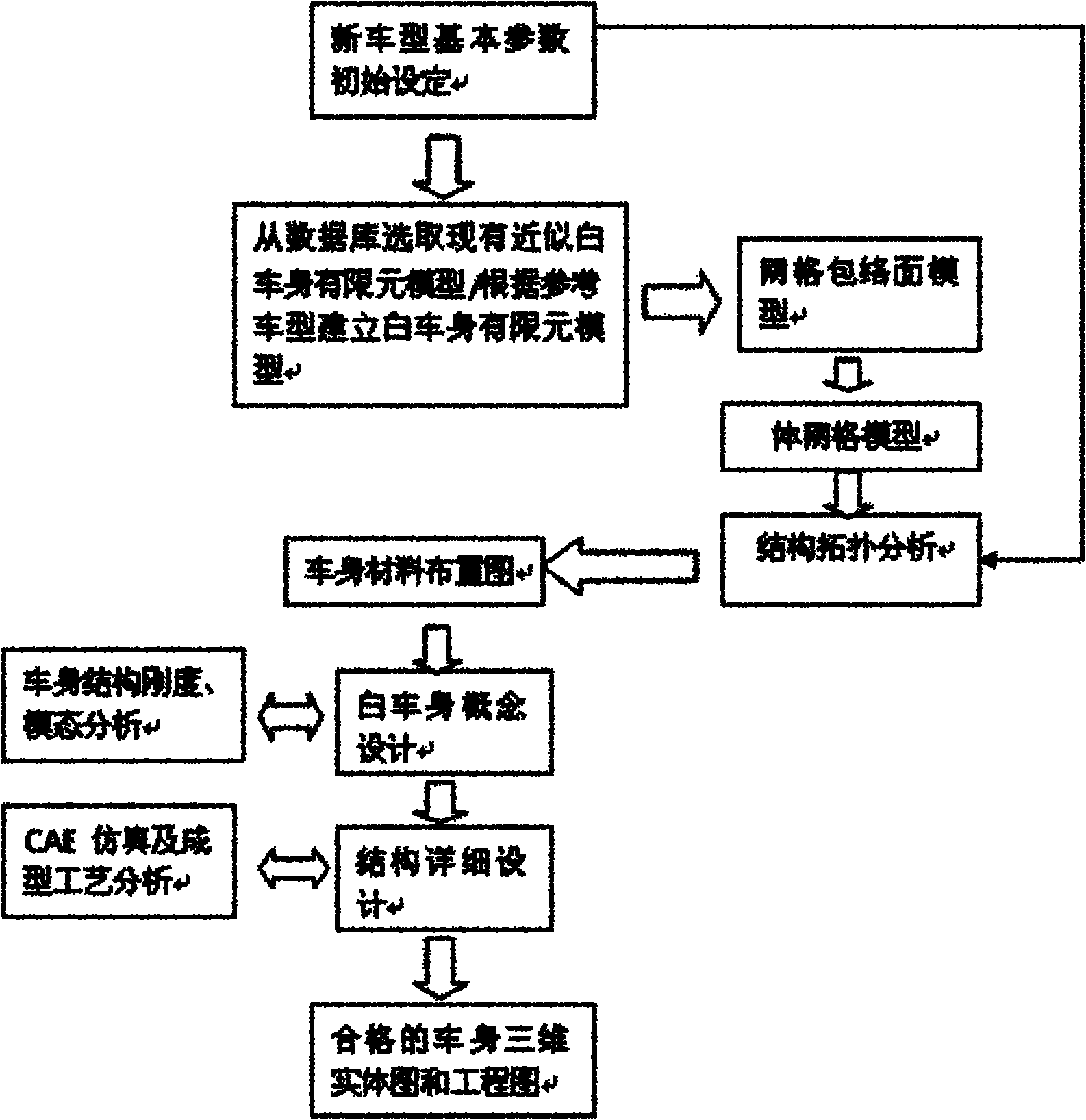

[0039] Example 1, such as figure 1 As shown, a design method for the layout of the body structure includes the following steps:

[0040] 1) Initial setting of basic parameters of new models, including size, model style and performance parameters;

[0041] 2) Select a body-in-white finite element model with similar structure and size from the finite element database established by the enterprise, or directly establish a body-in-white finite element model according to the reference model;

[0042] 3) Generate a finite element mesh envelope model according to the finite element model of the body-in-white;

[0043] 4) Generate a finite element body mesh model according to the finite element mesh envelope model;

[0044] 5) According to the requirements of topology optimization and the basic parameters initially set, on the basis of the finite element volume mesh model, establish design variables, optimization objectives, optimization constraints, boundary conditions, and conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com