Single-ended dual-wavelength high-precision distributed optical fiber temperature sensor

A distributed optical fiber and temperature sensor technology, applied in the field of light sensing, can solve the problems of unpredictable and unsatisfactory petrochemical reactions at 0.1°C, and achieve the effects of increasing measurement time, enhancing intensity, and improving signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

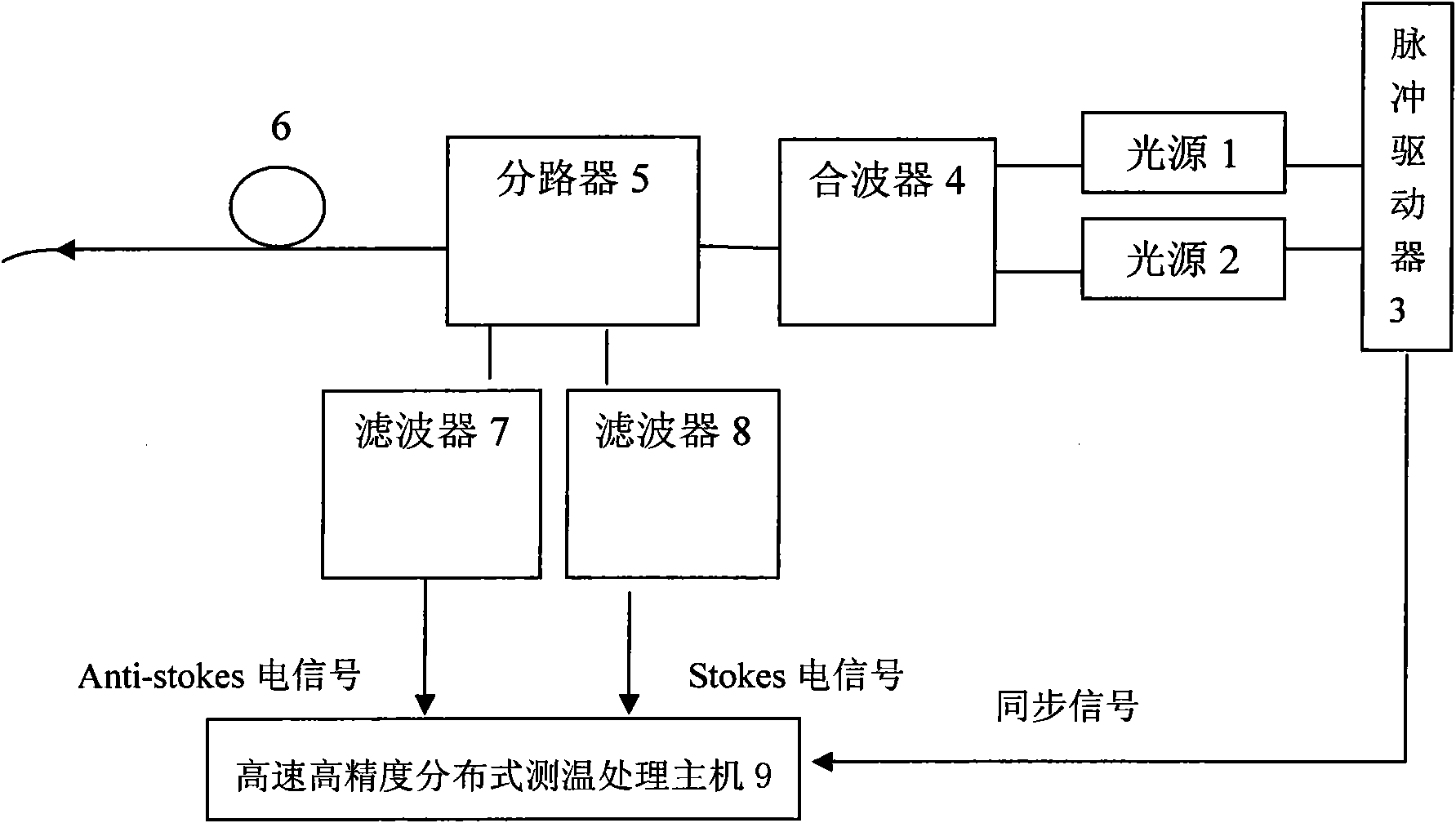

[0016] Embodiment 1: The pulse driver 3 is connected to the light source 1 and the light source 2, the light source 1 and the light source 2 are connected to the wavelength division multiplexer 4 at the same time, the wavelength division multiplexer 4 is connected to a fiber coupler 5, and one end of the fiber coupler 5 is connected to the sensor The optical fiber 6 and the two output ends of the optical fiber coupler 5 are connected to the wavelength division multiplexer 7 and the wavelength division multiplexer 8;

[0017] In this embodiment, light source 1 sends out a pulsed light signal with a pulse width of 10nm, light source 2 sends out a pulsed light signal with a pulse width of 9nm, and the two pulses have a width of 1nm. After optical fiber transmission, it enters the sensing fiber 6 through the fiber coupler 5. When the pulsed light signal is transmitted in the sensing fiber, backward Raman scattering occurs, and the backward Raman scattering light passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com