Novel gas-liquid heat-exchange device

A gas-liquid heat exchange and heat exchange plate technology, which can be used in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of high cost and large volume, and achieve extended service life and large heat exchange area. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

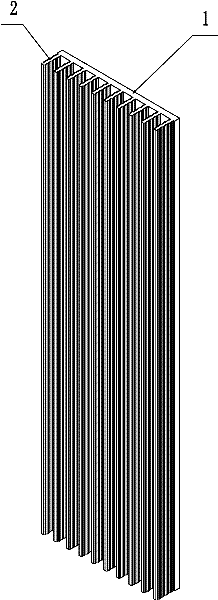

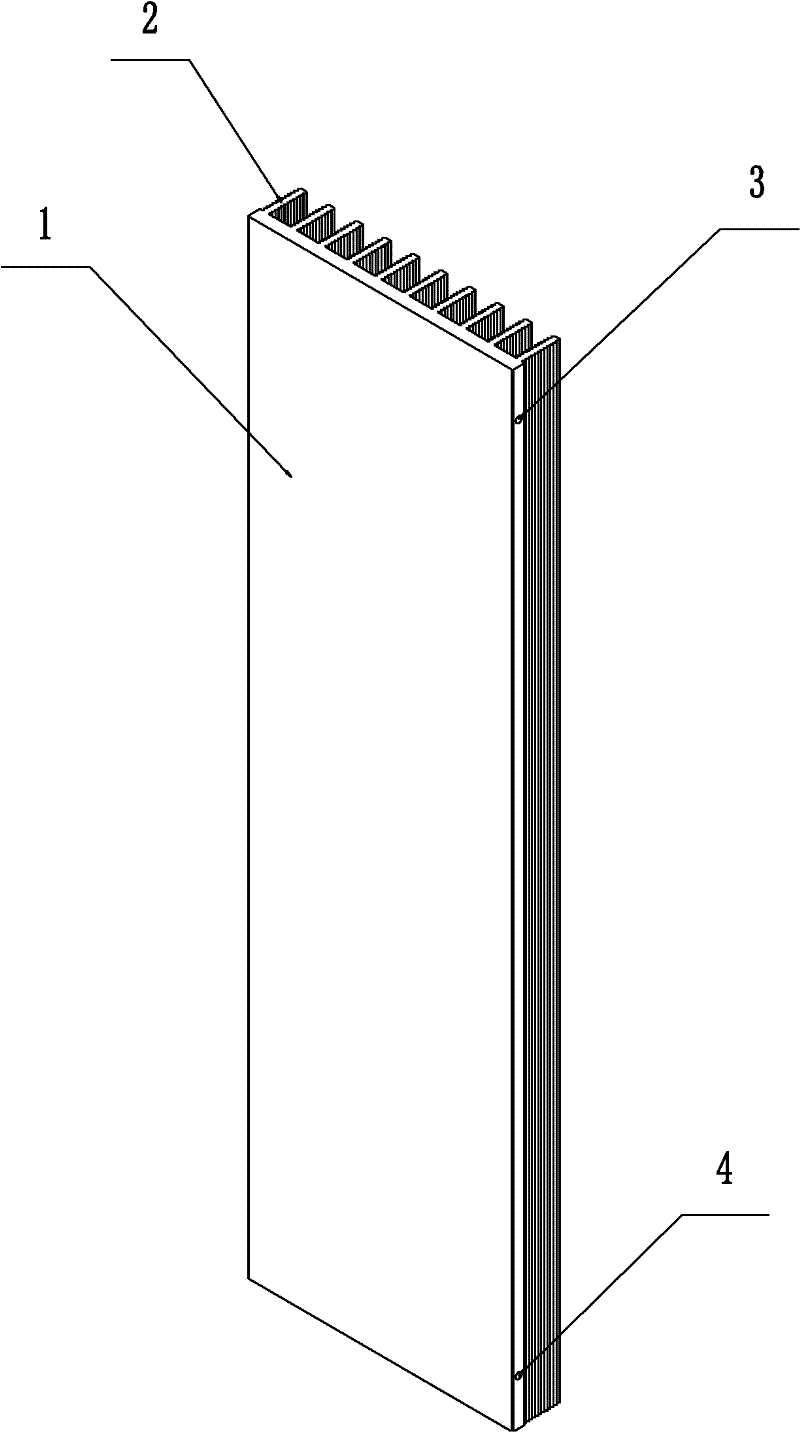

[0024] Example: Combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, the new gas-liquid heat exchange device provided in this embodiment is composed of the main heat exchange plate 1 and 10 auxiliary heat exchange fins 2 fixed on the main heat exchange plate 1. The main heat exchange plate The side end of the plate 1 is provided with inlet and outlet ports 3 and 4 on the same side, and the interior is provided with inlet and outlet main channels 5 and 6 connected to the inlet and outlet ports 3 and 4 respectively, and in this embodiment, the , The liquid outlet main channels 5 and 6 are arranged in parallel up and down inside the main heat exchange plate 1 . The 10 auxiliary heat exchange fins 2 are vertically and parallelly arranged on the main heat exchange plate 1, and each auxiliary heat exchange fin 2 is provided with an inlet and an outlet respectively connected with the inlet and outlet main channels 5 and 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com