Cement, mortar or concrete photoluminescent board and photoluminescent wall surface or ground and preparation methods thereof

A concrete slab and concrete technology, applied to floors, pedals, stairs, etc., can solve the problem of wasting electric energy and achieve the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

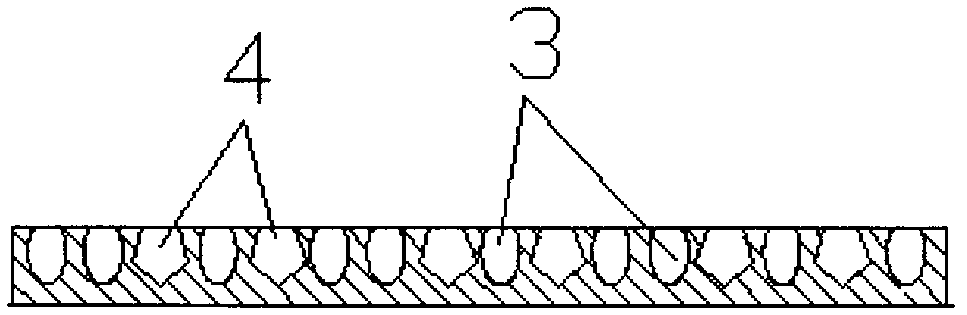

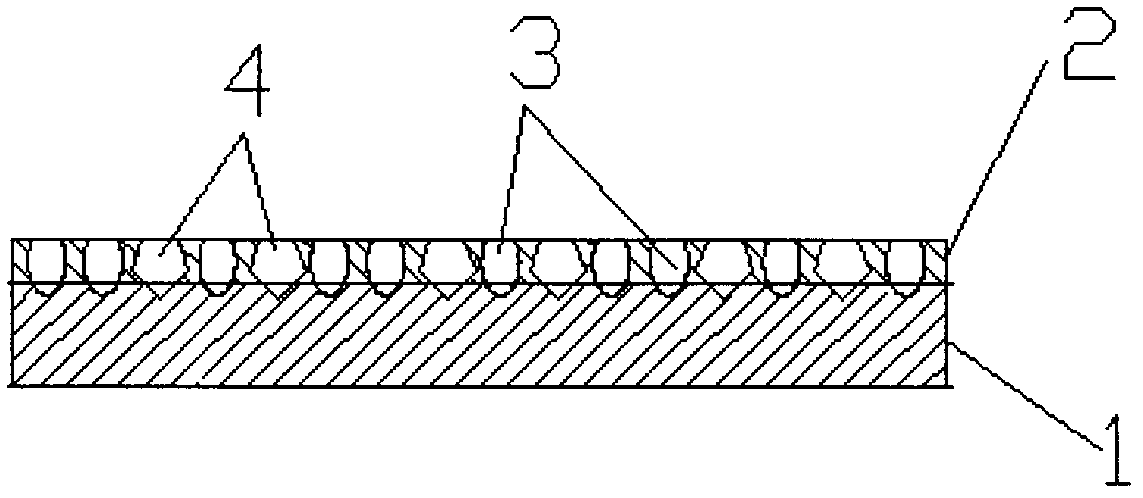

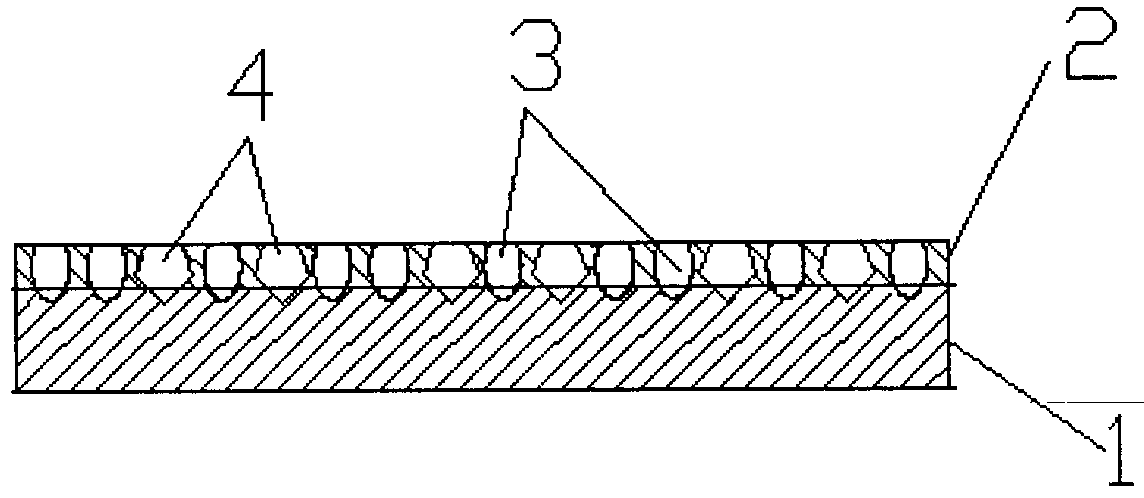

[0022] The accompanying drawing is a specific embodiment of the present invention.

[0023] The cement, mortar or concrete luminous board of the present invention has luminous material particles 3 inside the board body, and the luminous material particles are exposed on the surface of the board body and form the same smooth and smooth surface with the surface of the board body; The outer surface of the plate body 1 is composed of at least one surface with a luminous material layer 2, and there are luminous material particles 3 in the luminous material layer, and the particles exposed to the outside and the surface of the luminous material layer form the same smooth surface. There are also a large number of colored stones 4 inside the board body, and the colored stones are exposed on the surface of the board body and form the same flat and smooth surface with the surface of the board body; Colored stones 4, and the colored stones are exposed to form the same smooth surface as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com