Double gear drain valve for water tank

A drain valve and double-gear technology, applied in the field of sanitary ware, can solve problems such as complex structure, inconvenient operation, and large volume, and achieve the effect of precise and tight fit, easy operation, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

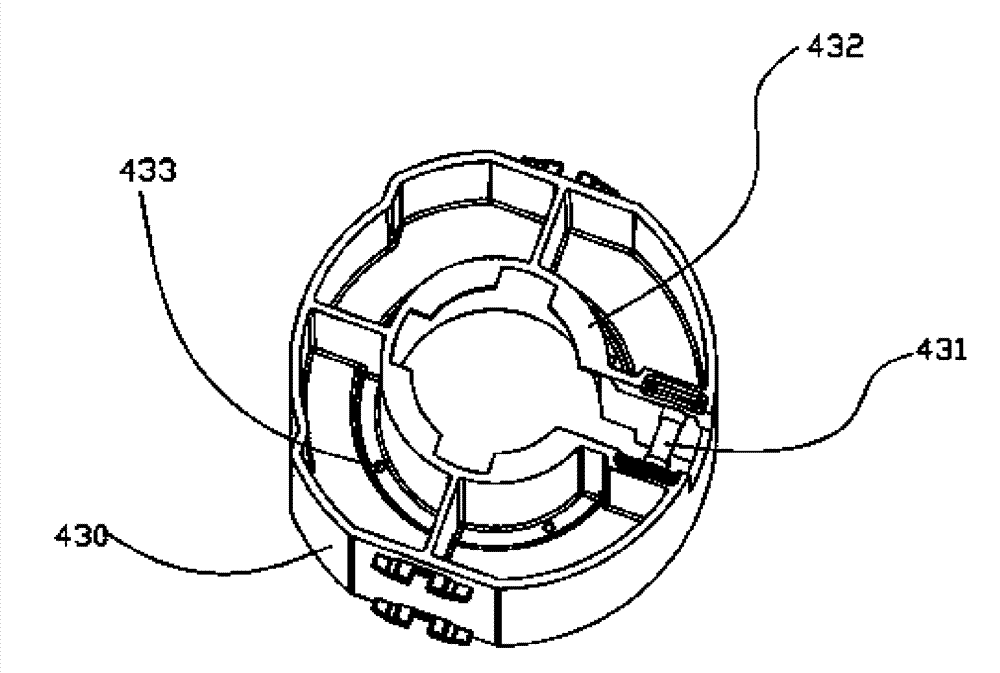

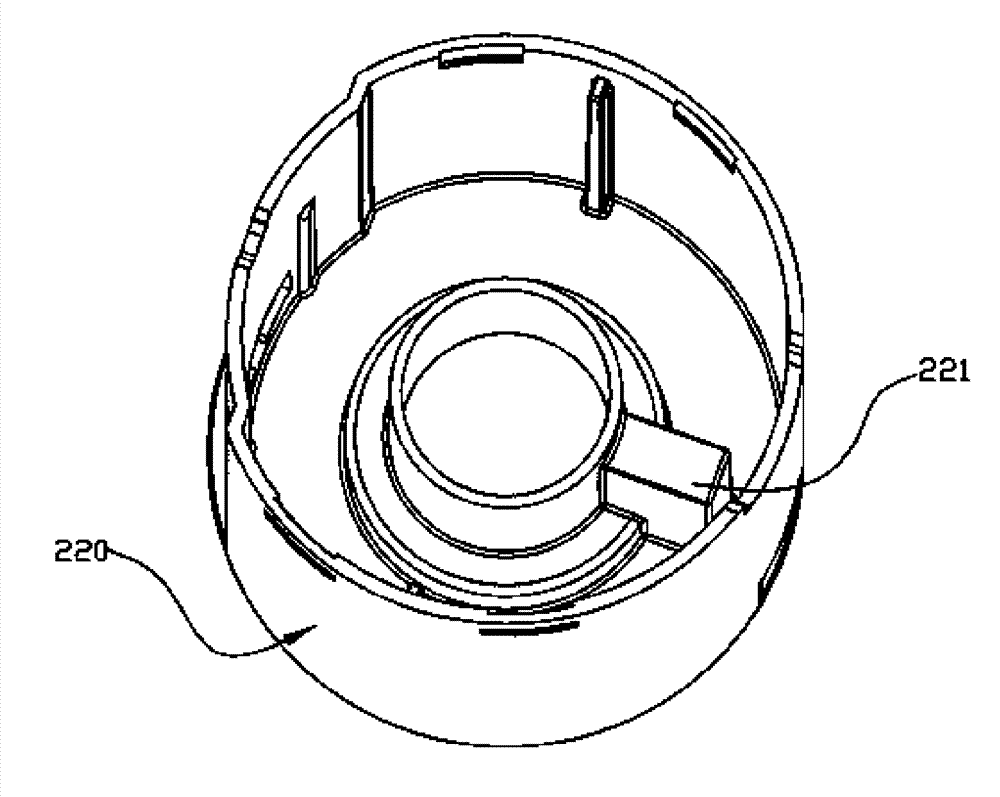

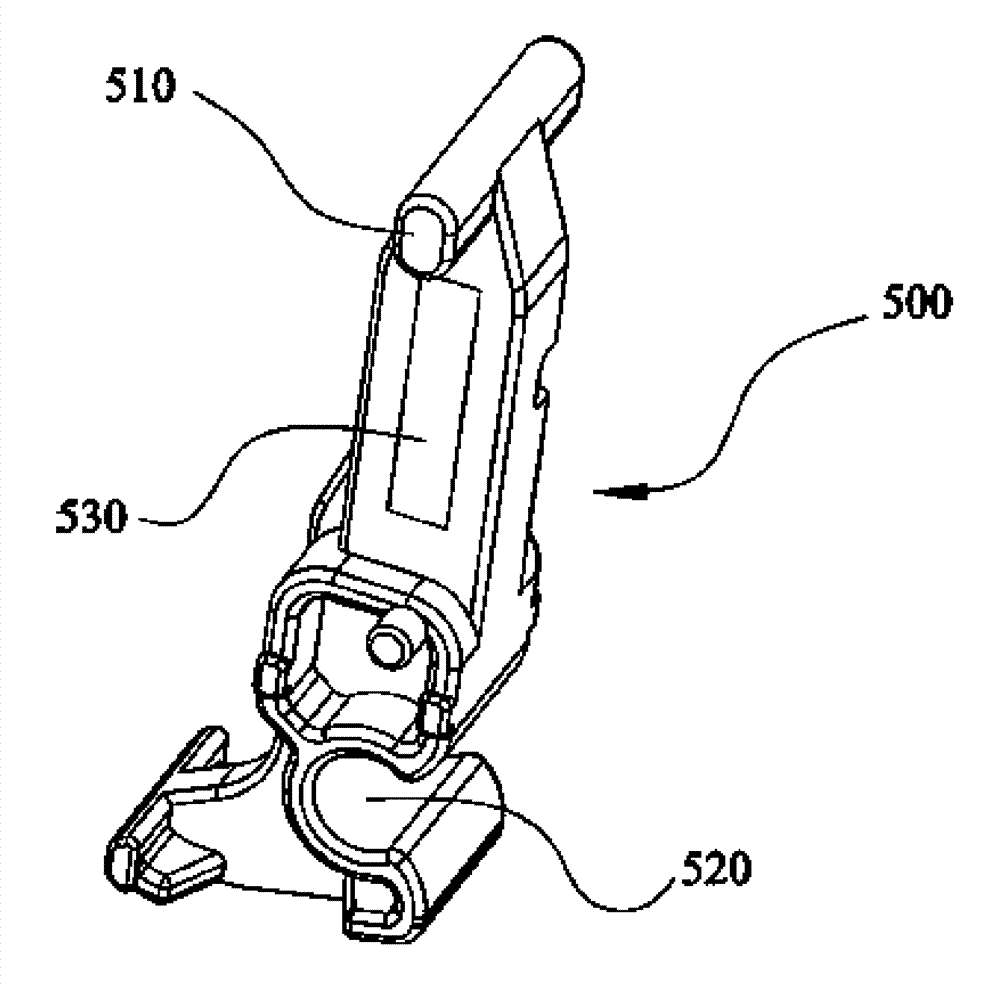

[0049] see Figure 1 to Figure 12 , is a schematic diagram of a dual-speed drain valve for a water tank provided by the present invention.

[0050] The double-stage drain valve for a water tank mainly includes an inner casing 100, a valve body, an actuating device, a full row of floating buckets, a half row of floating buckets, and a swing hook pivotally arranged on the half row of floating buckets. 500 and a water stop assembly 600.

[0051] An inner sleeve 100, which slides inside the valve body, a fixed ring 110 is provided on the outer surface of the inner sleeve 100, and a plurality of ribs interlocked with the half row of floating barrels are arranged on the outer surface of the inner sleeve at even intervals Strip 130, the upper end of the inner sleeve is provided with a shoulder, and the lower end is provided with a water-stop assembly 600. In this embodiment, the water-stop assembly is a sealing assembly. When the inner sleeve 100 slides relative to the valve body, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com