Novel carbon fiber sucker rod and manufacturing method thereof

A manufacturing method and carbon fiber technology, which is applied to drill pipes, earthwork drilling, drilling equipment, etc., can solve the problems of narrow use surface and inconvenient operation, and achieve the effects of reducing the number of downhole operations, fast installation speed, and saving downhole operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

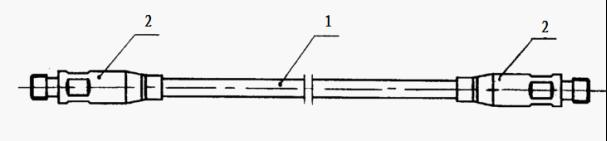

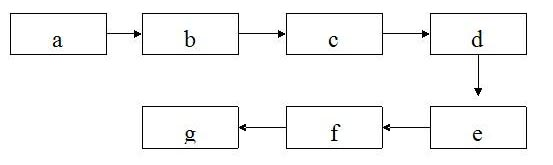

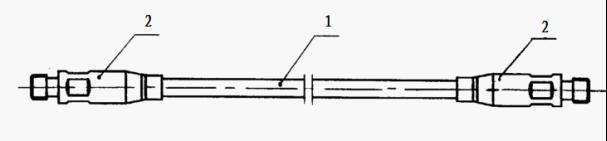

[0017] The technical solution of the invention is: the main raw materials are T300 carbon fiber-12K, epoxy resin, methylhydrotetraylphthalic anhydride, accelerator, and film release agent, and are formed by pultrusion. Its technological process is as follows:

[0018] a. Arranging the yarn, put the carbon fiber filament on the creel, and then release the filament.

[0019] b. Dipping, fully immersed through the creel, including 100 parts of epoxy resin, 80 parts of methylhydrotetraylphthalic anhydride, 2 parts of accelerator, and 2-6 parts of release agent;

[0020] c, preheating, the preheating temperature is 50 + 10°C

[0021] d. Curing molding, curing molding is divided into three zones for temperature control, the temperature of the first zone is 135 + 10°C, the temperature in the second zone is 170 + 5°C, the temperature in the third zone is 200 + 10°C;

[0022] e. Post-curing, the temperature in the post-curing zone is 210 + 10°C;

[0023] f. Traction, towed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com