Process for continuously producing isobutyric acid

A technology of isobutyric acid, continuous method, applied in the separation/purification of carboxylic acid compounds, preparation of carboxylate, chemical instruments and methods, etc., can solve problems such as difficulty in realizing continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

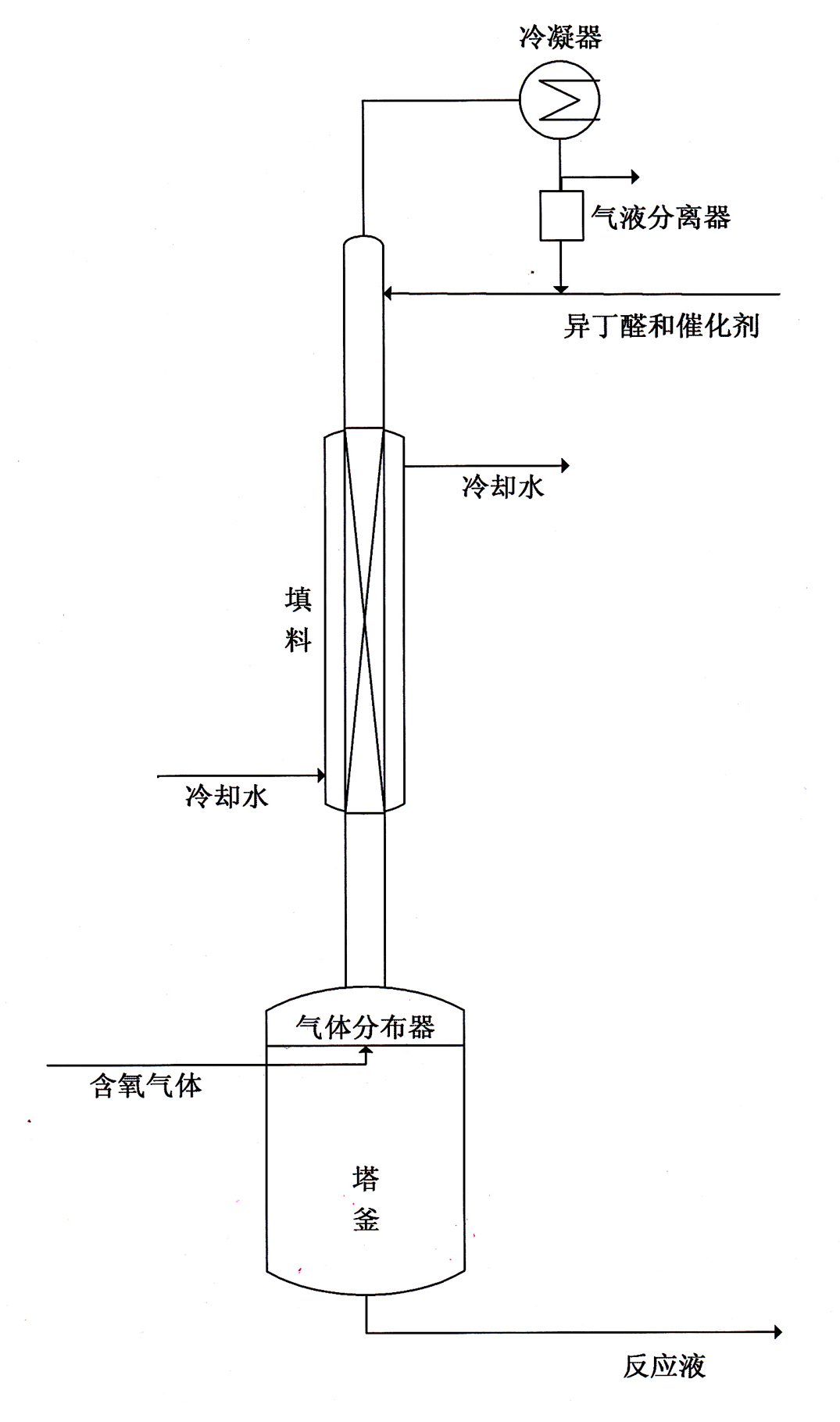

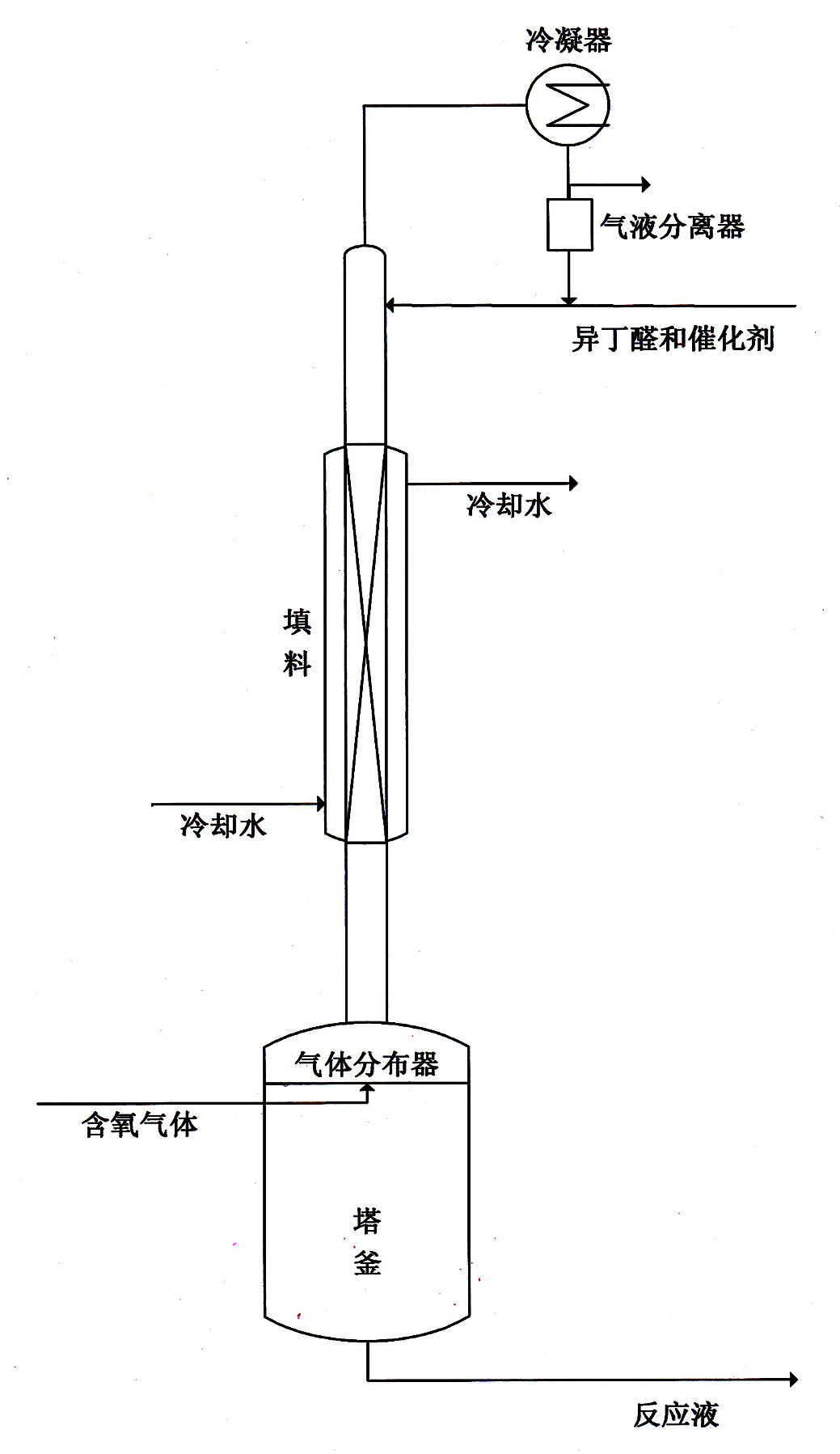

Method used

Image

Examples

Embodiment 1

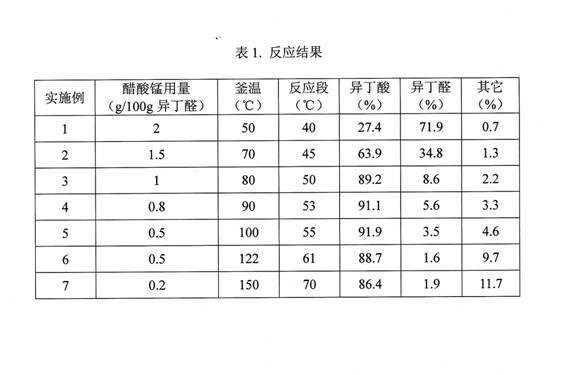

[0013] Embodiment 1, the reactive distillation device is made of reaction kettle, rectification tower body and the condenser and gas-liquid separator at the atmospheric pressure outlet of tower top, reaction kettle 2L, rectification tower internal diameter 8cm, height 2m, in the middle of tower body It is equipped with a packing with a height of 1.8m (the packing can be porcelain ring or stainless steel packing). The reaction material is isobutyraldehyde, the reaction section of the rectification tower is equipped with a jacketed water cooling device, and the catalyst is an isobutyric acid solution with a weight content of 10% manganese acetate. The isobutyraldehyde feed rate is 40g / h, the configured catalyst feed rate is 8g / h, the air flow rate is 50L / h, and the reaction product is continuously discharged to keep the liquid level in the reactor at the bottom of the tower constant (the same below). Its discharge rate is 50.5g / h, and the gas flowing out from the top of the towe...

Embodiment 2

[0014] Embodiment 2, reaction unit, feeding and discharging mode and product analysis method are with embodiment 1, and catalyzer is the manganese acetate isobutyric acid solution that weight content is 15%, and isobutyraldehyde feed rate is 40g / h, and catalyzer feed rate is 4g / h, the discharge rate of the reaction product is 50g / h, the air flow rate is 50L / h, the kettle temperature is 70°C, and the reaction zone temperature is 45°C. The reaction results are shown in Table 1.

Embodiment 3

[0015] Embodiment 3, reaction unit, feeding and discharging mode and product analysis method are with embodiment 1, and catalyzer is the manganese acetate isobutyric acid solution that weight content is 20%, and isobutyraldehyde feed rate is 40g / h, and catalyzer feed rate is 2g / h, the discharge rate of the reaction product was 50.4g / h, the air flow rate was 50L / h, the kettle temperature was 80°C, and the reaction zone temperature was 50°C. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com