Method for testing concentration ratio of slurry in wet flue gas desulfurization absorption tower in thermal power plant

A technology of wet flue gas desulfurization and concentration ratio, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. Issues such as less than guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

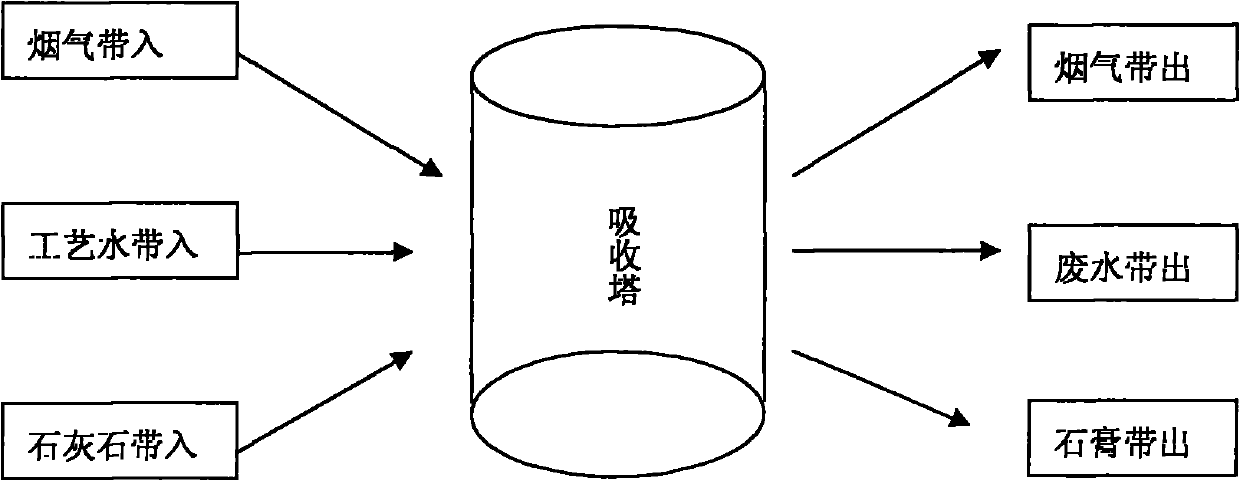

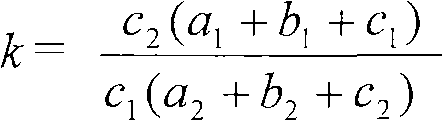

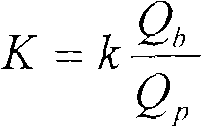

Method used

Image

Examples

Embodiment 1

[0065] For example, the concentration rate of the absorption tower of the main equipment of a limestone-gypsum wet desulfurization system of a certain 300MW unit of a power plant in North China is determined. During the experiment, the absorption tower operated stably, and all the indicators were within the involved range. Also monitor the following indicators:

[0066] (1) Test process water volume. Process water mainly includes: flushing water for demisters, flushing water for absorption tower pipes, instruments, etc., cleaning water for vacuum belt conveyors, gypsum cleaning water, cooling water for oxidation fans, circulating pumps, etc., water for limestone pulping systems, etc., of which flushing water and The cooling water is collected into the sump and pumped into the absorption tower by the sump pump.

[0067] Table 1 shows the process water consumption test results of the four systems in the first phase of the power plant:

[0068] Table 1 Incoming water volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com