Multi-model predictive control method for component content in process of extracting rare earth

A component content, predictive control technology, applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of complex model, unable to reflect the dynamic changes of the extraction process, and no control amount given.

- Summary

- Abstract

- Description

- Claims

- Application Information

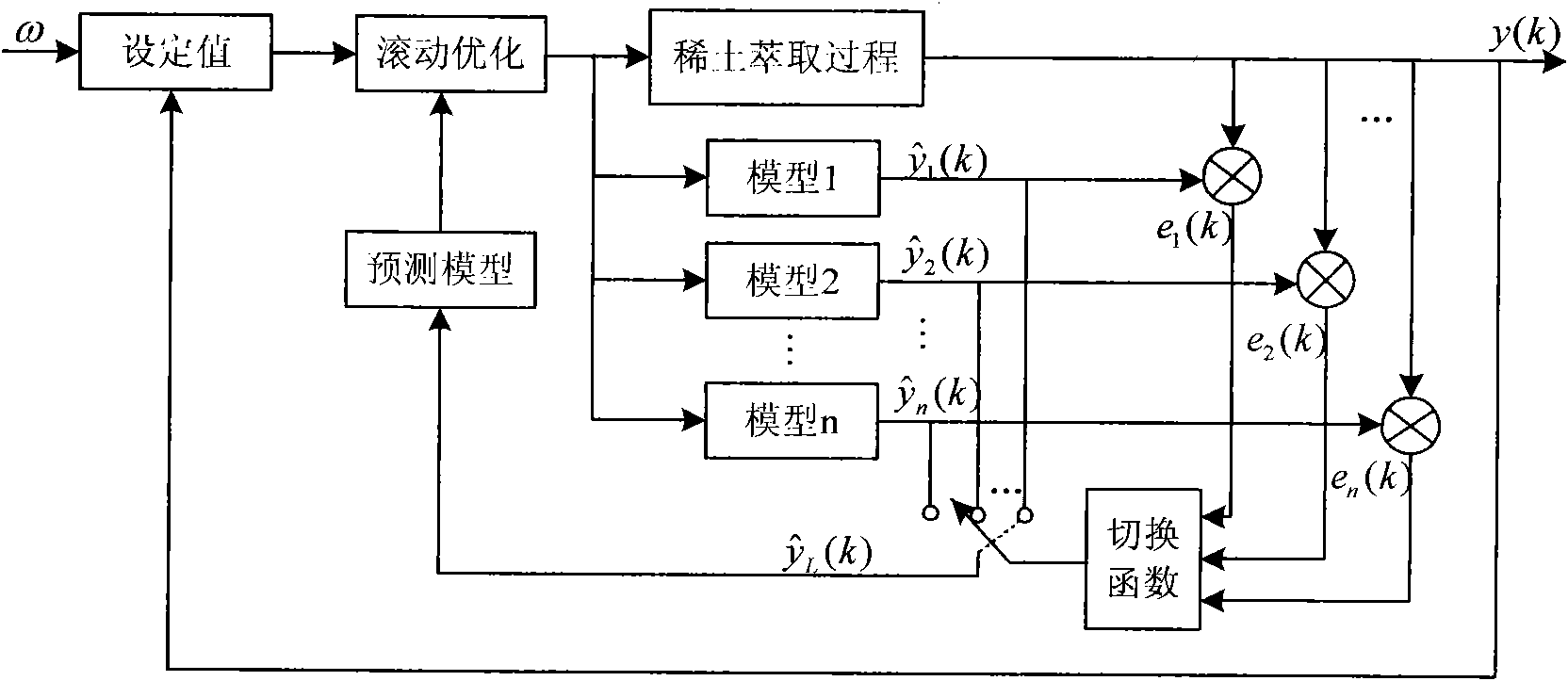

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

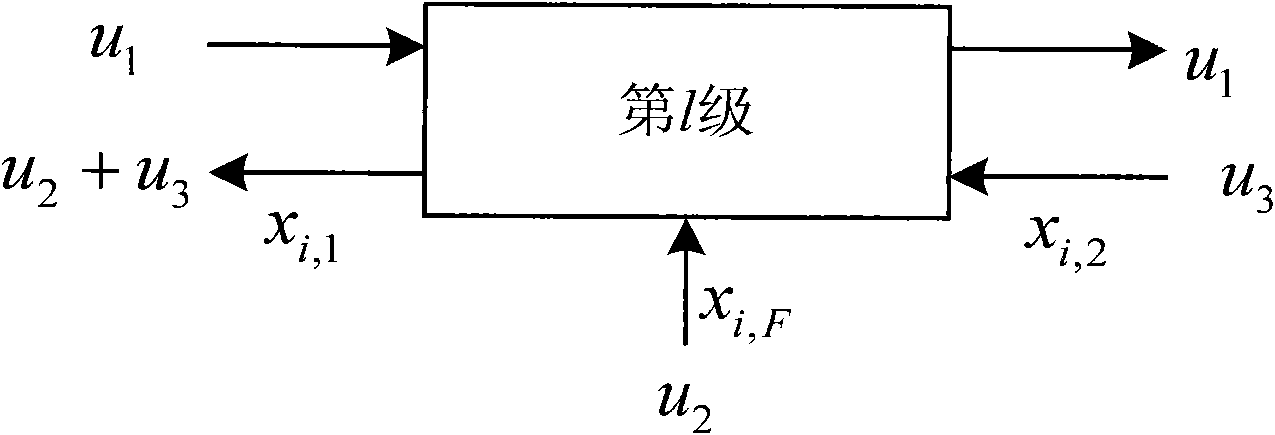

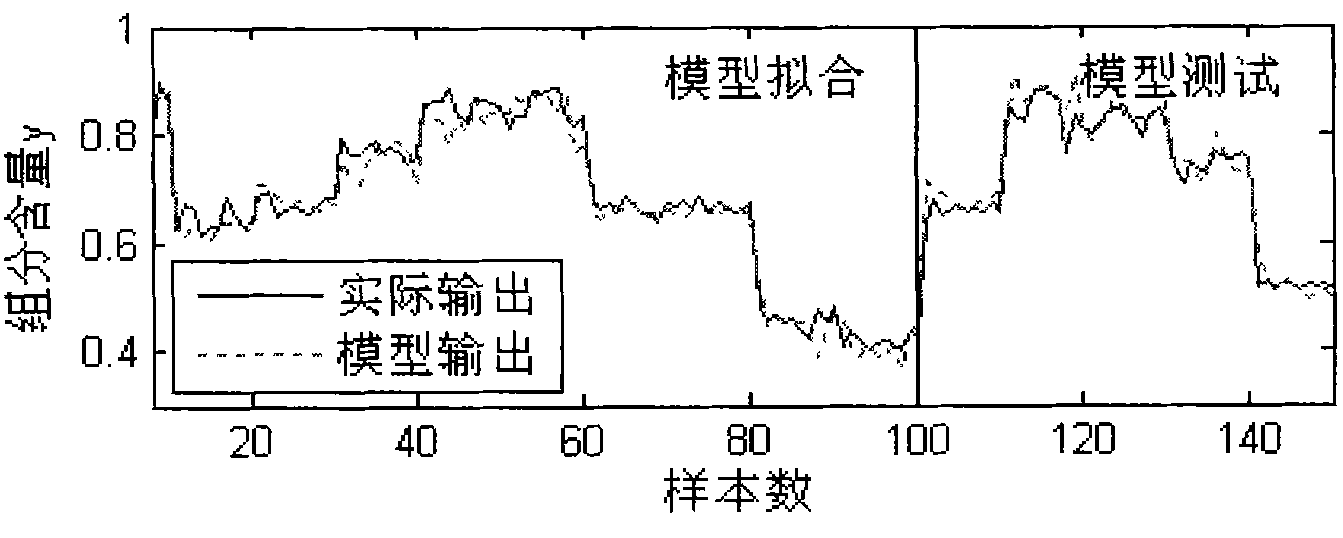

[0106] The implementation of the invention utilizes the actual measurement data of the extraction and separation product yttrium of a rare earth company to establish a multi-linear model for online estimation of the rare earth component content. Set up a monitoring point at the sensitive level of the rare earth extraction process, and estimate the purity of the element components of the monitoring point online through the model. The content of the element components is controlled within the set range.

[0107] 150 groups of effective data were collected at the monitoring points, and the first 100 groups were clustered and analyzed to obtain the four cluster centers shown in Table 1, which are the steady-state operating points of the extraction process, which were identified with the corresponding classification data set Corresponding to the local linear model of the operating point, the initial model Model 1 to Model 4 of the element composition content y(k) is obtained, as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com