Culvert raw material delivery and smoke dust recovery device and method for smelting container

A raw material conveying and recycling device technology, applied in the field of metallurgy, can solve the problems of strong viscosity, reduce the utilization effect of flue gas waste heat boiler, easy to block heat exchange pipes, etc. The effect of dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

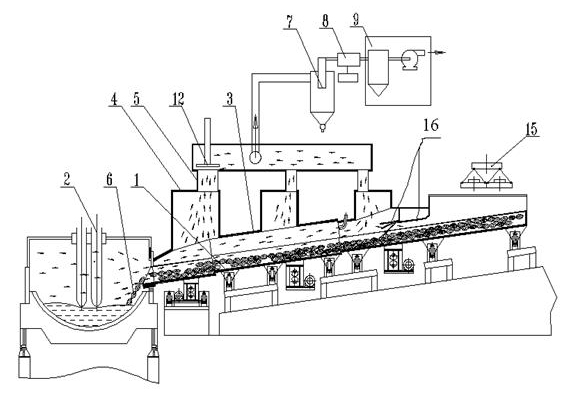

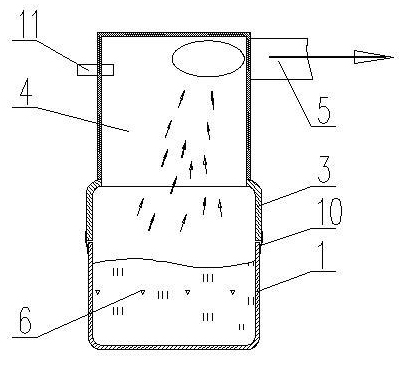

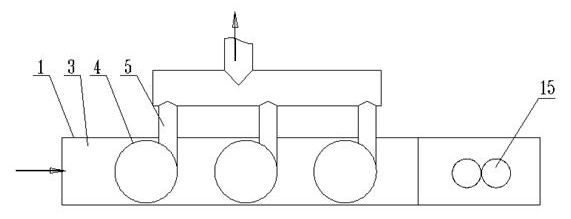

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure, the ducted smelting container raw material conveying and dust recovery device of the present invention includes a raw material conveying trough 1 inclined or parallel to the horizontal plane, and the discharge end of the raw material conveying trough 1 Extending into the smelting container 2, the upper part of the raw material delivery tank 1 is provided with a sealing cover 3, which forms a channel for raw material delivery and flue gas circulation between the sealing cover 3 and the raw material delivery tank 1, and the upper part of the sealing cover 3 is communicated with Three (according to the actual application, it can be one or more) dust fall chambers 4 for settling dust in the flue gas. The dust fall chambers 4 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com