Flooded type evaporator structure

A flooded evaporator and evaporator technology, applied in refrigeration and liquefaction, refrigeration components, refrigerators, etc., can solve the problems of gaseous refrigerants being easily entrained with liquid refrigerants, liquid shock, etc., to prevent being sucked into the compressor, and the concept is ingenious , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

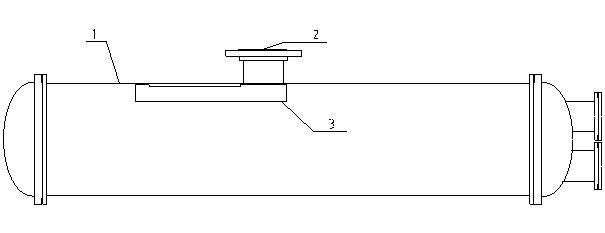

[0007] The gist of the present invention is to solve the compressor liquid hammer phenomenon caused by the unreasonable structure of the liquid baffle in the existing flooded evaporator. , Realize the secondary separation of the vapor-liquid mixture of the refrigerant in the trough-shaped liquid baffle, effectively preventing the liquid shock caused by the liquid refrigerant being sucked into the compressor. The present invention will be described in further detail below in conjunction with the accompanying drawings.

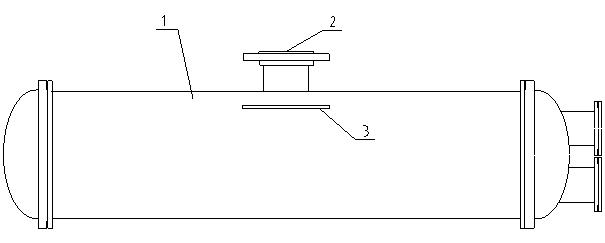

[0008] figure 1 The structural scheme adopted in the prior art is shown, including a horizontal or horizontal evaporator body 1, which is composed of a cylindrical shell and end caps at both ends, and the cavity formed by the cylindrical shell and the end caps A heat pipe immersed in liquid refrigerant is arranged inside, a gaseous refrigerant outlet pipe 2 penetrating through the shell wall is fixedly installed on the upper wall of the cylindrical shell, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com