Back coating type glass reflector

A reflector and back plating technology, applied in the field of reflectors, can solve the problems of reducing the reflection coefficient, reducing the maintenance coefficient of lamps, aging of the reflective layer, etc., and achieving the effect of increasing light efficiency, low thermal expansion coefficient, and not easy to aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

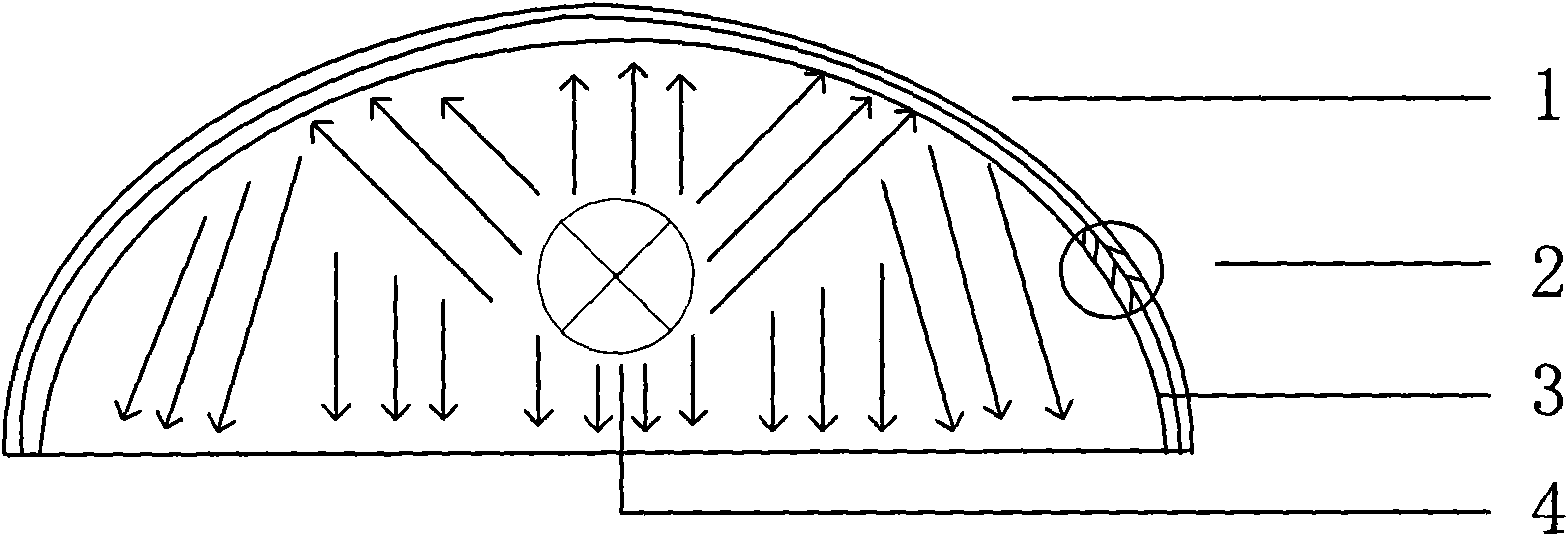

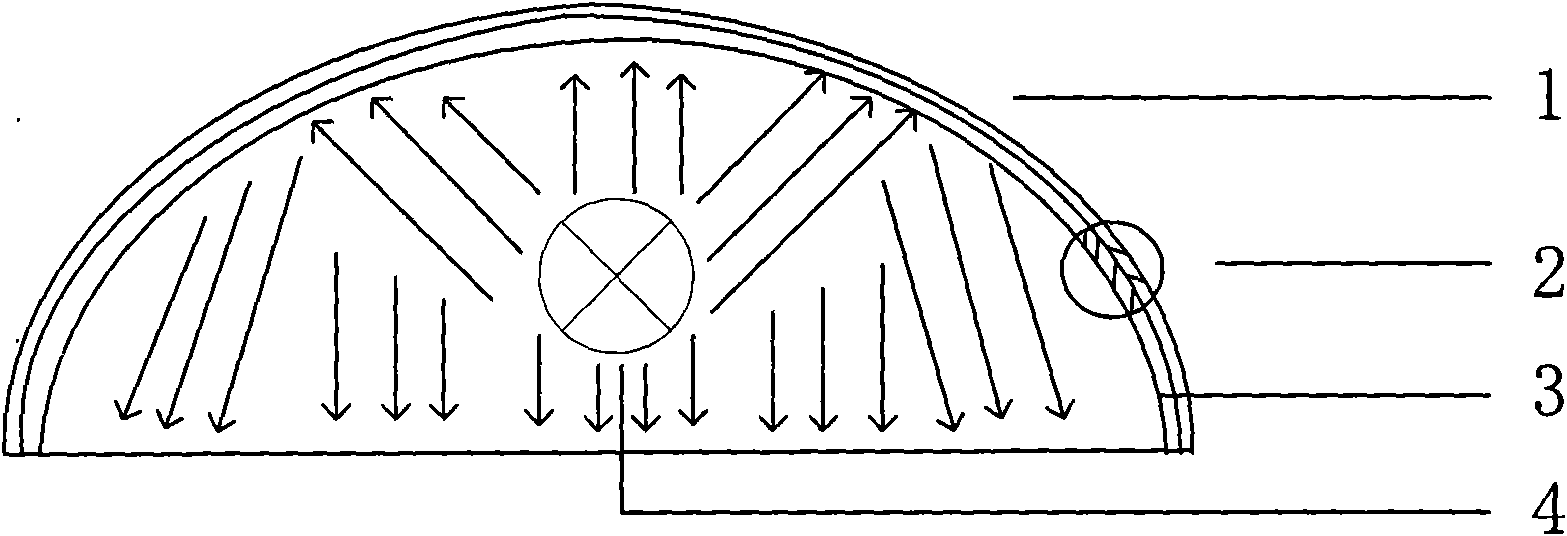

[0020] exist figure 1 Among them, the reflector is composed of a housing 1 and a reflective film 2. The housing 1 has an arc-shaped section, and the reflective film 2 covers the arc-shaped outer surface 3 of the housing. The reflective film 2 is composed of an outer protective layer 5 and a reflective layer 6 . The reflective layer 6 is coated on the outer surface 3 of the casing, and the outer protective layer 5 is close to the reflective layer 6 and coated on the reflective layer 6 . The light emitted by the light source 3 is reflected by the reflective film 2 and irradiates the surface of the object.

[0021] The housing 1 is made of high borosilicate glass instead of the traditional high-purity aluminum plate. Compared with traditional high-purity aluminum plates, high borosilicate glass has obvious advantages in reflectivity and heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com