Deep processing method of oil sunflower seeds

A technology for deep processing of sunflower seeds, which is applied in food processing, fat oil/fat production, fat production, etc. It can solve the problems of poor quality of sunflower meal, low oil yield in husking and pre-pressing extraction process, and achieve oil resource saving, The effect of high feed value and low crude fiber content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

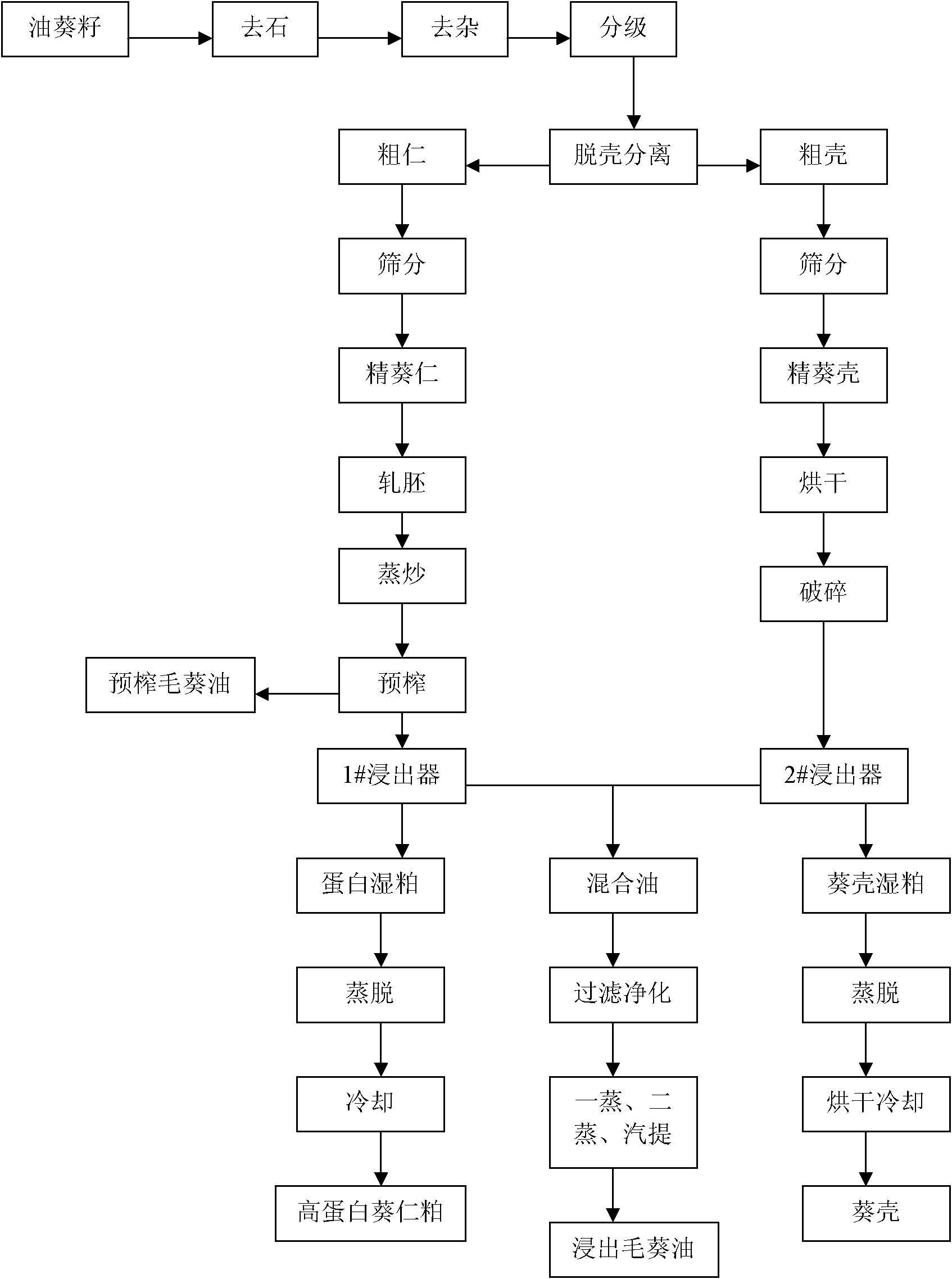

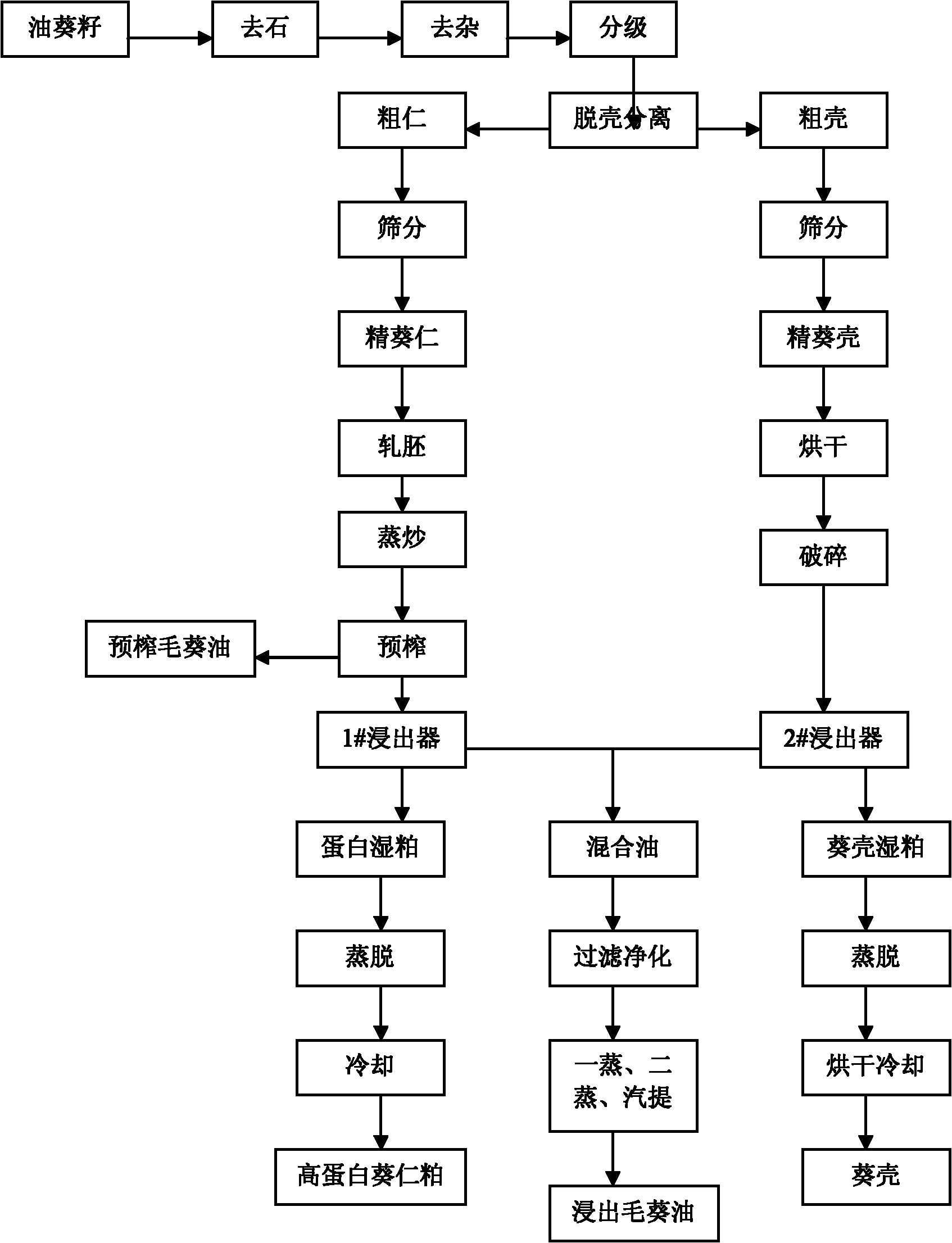

[0021] like figure 1 Shown, a kind of oil sunflower deep processing method, the steps are as follows:

[0022] (1) Remove impurities from the oil sunflower seeds, use a cleaning grading sieve, and divide the oil sunflower seeds into three particle sizes (large, medium, and small) according to the particle size (above 3.4mm, between 2.6-3.4mm, and below 2.6mm). It is beneficial for the subsequent shelling machine to shell sunflower seeds with different particle sizes at different frequencies to improve the shelling efficiency; and then separate the shells to obtain sunflower kernels and shells;

[0023] (2) Sunflower kernels are pre-pressed after flaking, steaming and frying to obtain sunflower cakes and pre-pressed wool sunflower oil. The flaking uses a double-roller hydraulic flaking machine, and the thickness of the flaking is 0.4-0.45mm, which is beneficial to destroy the tissue cells of the sunflower kernel embryos, and prepares for the next steaming and frying to complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com