Two-particle nano-magnetic lubricating oil

A nano-magnetic and lubricating oil technology, applied in the field of lubricating oil lubrication preparation and application theory, can solve the problems of reducing friction coefficient, instability, etc., and achieve the effects of improving stability, preventing agglomeration, and promoting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

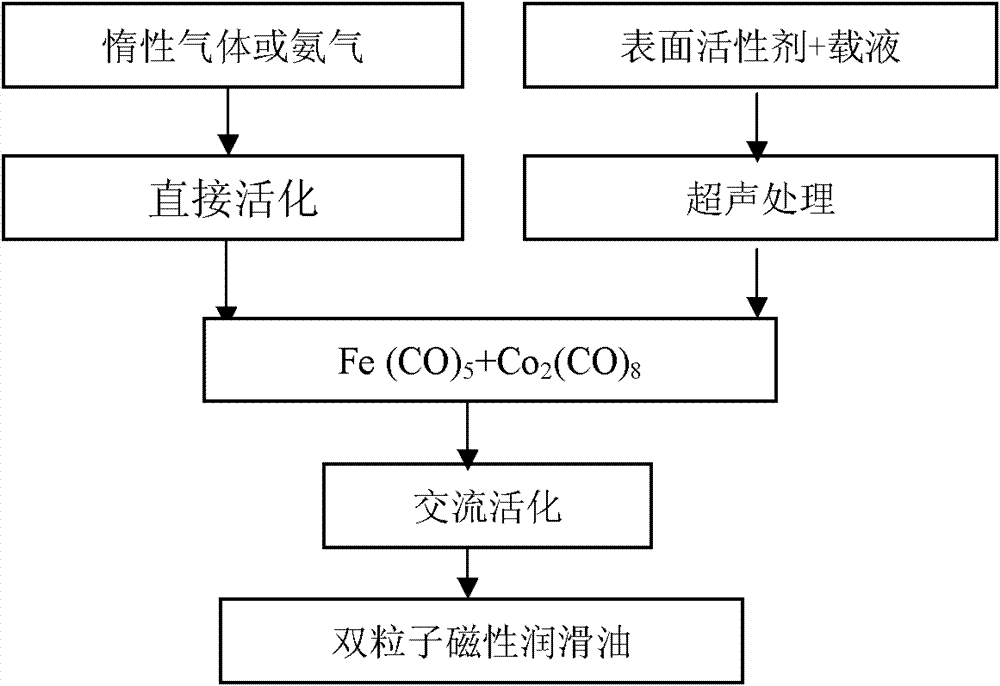

Method used

Image

Examples

Embodiment 1

[0021] The reaction device used in this example is a reaction device commonly used in the art, and the raw materials used are all common commercially available commodities.

[0022] (1) Prepare the preparatory solution: weigh the surfactant polyisobutenylsuccinimide and the carrier liquid white oil according to the mass ratio of 1:8.5, mix the surfactant and the carrier liquid, and ultrasonicate for 15 minutes;

[0023] (2) Install and check the test device: Pour the mixed solution from the previous step into the heating reaction chamber, connect the reaction device, pass inert gas argon and ammonia into the reaction chamber, and observe the bubbles in the gas cylinder to judge whether the gas path is smooth , and remove the air in the reaction chamber; at the same time, turn on the water pump to check whether the waterway is smooth;

[0024] (3) Add iron pentacarbonyl and dicobalt octacarbonyl in the preparatory liquid, the mol ratio of the added iron pentacarbonyl and surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com