Marsh gas biological desulphurization energy-saving method

A biological desulfurization and biogas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of difficult control, difficult removal of hydrogen sulfide, harsh conditions, etc., to achieve easy control, suitable for survival and reproduction, and loose conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

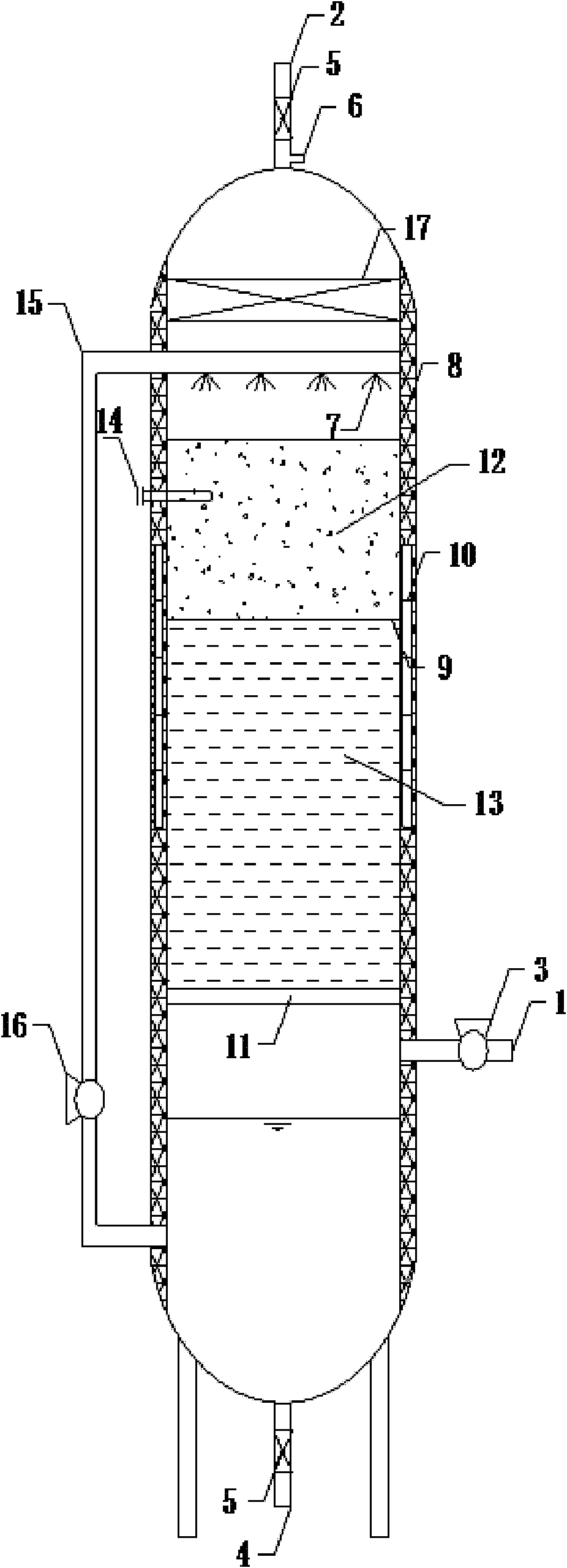

[0014] Specific implementation mode one: combine figure 1 As shown, the energy-saving method of biogas bio-desulfurization in this embodiment is carried out according to the following steps: 1. Add Thiobacillus denitrificans and nitrifying bacteria into the nutrient solution, and then spray them on the filler. Cultivate under the conditions of 6.7 to 7.3 for 2 weeks to form a biofilm; 2. The biogas reacts with the biofilm to complete the biogas desulfurization; wherein the volume ratio of Thiobacillus denitrificans and nitrifying bacteria in step 1 is 2:1; step Every 1L of a nutrient solution contains 5g of Na 2 S 2 o 3 ·5H 2 O, 1g of K 2 HPO 4 , 1g of KNO 3 , 1g of NaHCO 3 , 0.2g of MgSO 4 ·7H 2 O, 1g of NH 4 Cl, 4g NaNO 2 , 0.5g of FeSO 4 ·7H 2 O and the remainder of distilled water; the filler in step 1 adopts two layers of polyurethane foam filler, which are respectively a soft polyurethane foam filler layer and a rigid polyurethane foam filler layer, and the ...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, Thiobacillus denitrificans and nitrifying bacteria are added to the nutrient solution, and then sprayed on the filler. Conditions for 2 weeks to form a biofilm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0023] Specific embodiment three: The difference between this embodiment and specific embodiment one is that in step one, Thiobacillus denitrificans and nitrifying bacteria are added to the nutrient solution, and then sprayed on the filler. Conditions for 2 weeks to form a biofilm. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com