Polyolefin resin for long-lasting drip film and preparation method thereof

A polyolefin resin and polyolefin technology, applied in the field of polyolefin long-term drip film resin and its preparation, can solve the problems of short drip life, poor durability, no double bond reactive groups, etc., to improve flow Droplet life, reduced homopolymerization tendency, and increased affinity

Active Publication Date: 2011-04-06

CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the poor compatibility between the dripping agent used in the internal addition method and the base resin, it is easy to migrate, and after migrating to the surface, it is easy to leave the surface of the film due to volatilization, dissolution, washing or friction, so the dripping life is short

The other is the external coating method, which is to apply the waterproof dripping agent solution on the surface of the plastic film to make it hydrophilic. The external coating method is easy to use and has excellent wettability, but there is a gap between the dripping agent coated and the plastic film. Poor adhesion, high cost, poor durability, inconvenient processing, etc., so its application is limited

The dripping film is produced by the internal addition method. The dripping effect of this film is short, generally only about three or four months. The Chinese invention patent "a long-term non-dripping film for agriculture" (application number 02131797.6, publication number CN1485359A ), is to use the method of copolymerization to increase the molecular weight of the dripping agent to delay its loss in the dripping film. The synthetic dripping agent has no double bond reactive group, and it belongs to the internal addition type like the traditional dripping agent. The dripping film dripping duration of the dripping agent is also shorter

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

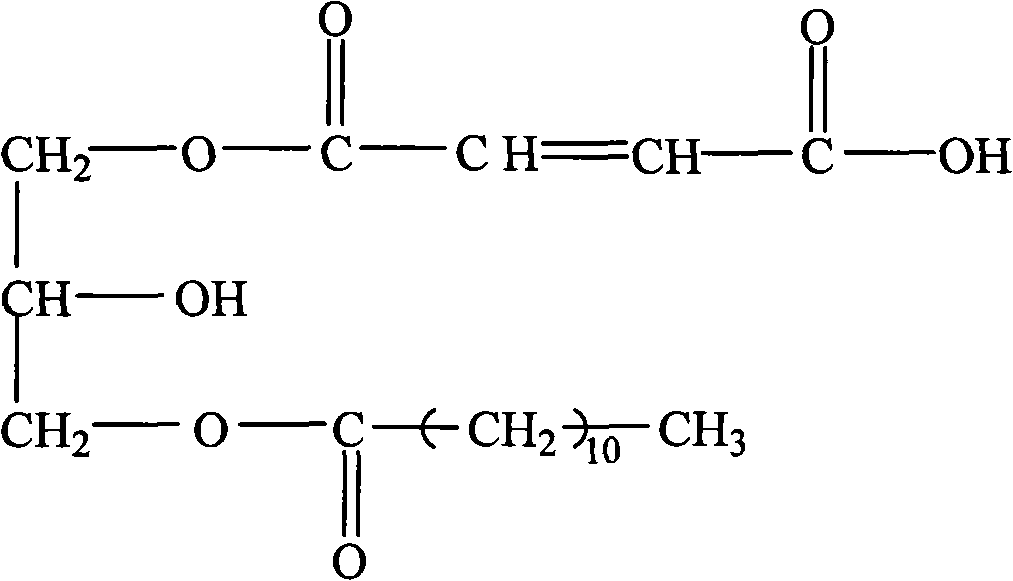

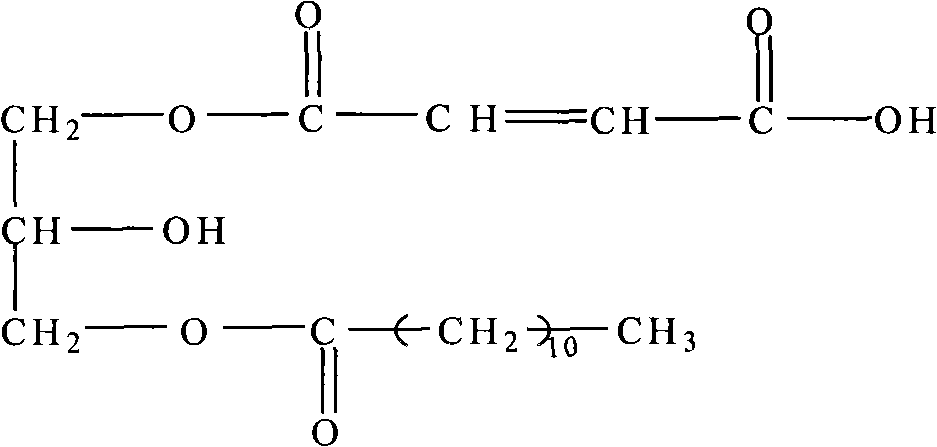

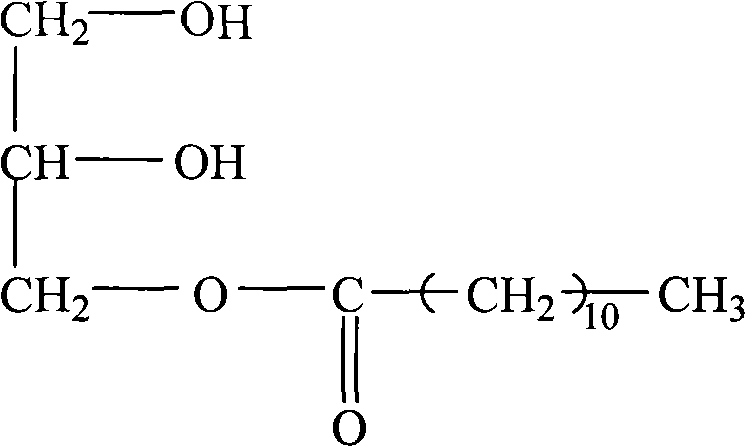

The invention provides a polyolefin resin for a long-lasting drip film and a preparation method thereof, wherein a functional monomer which is applied to the polyolefin resin provided by the invention is obtained by reacting glyceryl monolaurate with maleic anhydride, then the polyolefin resin is subjected into pre-radiation treatment by using beta ray and gamma ray, the polyolefin resin which is subjected into pre-radiation treatment is mixed with a polyolefin resin, and then the mixture is added into a reaction type extruder, the functional monomer and an electronic reagent are added into the reaction type extruder by means of a liquid charging opening of the reaction type extruder so as to react, extrude and graft, and then the grafted product is subjected into check rod, cooling and granulation to obtain the polyolefin resin for long-lasting drip film. The drip film which is obtained by blow moluding with the polyolefin resin provided by the invention has an effective duration of 21 to 35 days and 9 to 12 months under a condition of accelerated drip test of 60 DEG C and a condition of outdoor buckle tent, and the effective duration of a commercial drip film under the same condition is 6 to 8 days or 3 to 4 months, respectively.

Description

technical field The invention relates to a resin for polyolefin long-term dripping film and a preparation method thereof. Background technique Polyolefin resins are widely used in agricultural greenhouse plastic greenhouses. In winter and spring, the temperature and humidity inside and outside the plastic greenhouse are quite different, and the non-polar polyolefin resin is not hydrophilic. A large number of water droplets are condensed on the inner surface of the greenhouse film. The formation of water droplets reduces the light transmission of the film on the one hand and hinders the growth and development of crops. In addition, when tiny water droplets fall on crop flowers, stems, leaves or fruits, it is easy to cause frostbite, rotten seedlings, rotten seedlings or pests and diseases in crops, which directly reduces the yield and quality of crops. The polyolefin drip film improves the non-polar characteristics of the polyolefin resin, reduces the interfacial tension o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F255/02C08J3/28C08L23/06C08L23/08

Inventor 姚占海殷敬华宋永贤姜国伟

Owner CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com