Method for extracting L-threonine

A technology for threonine and threonine fermentation broth, applied in the field of biochemical industry, can solve the problems of inconvenient operation, cumbersome steps, influence on the extraction purity of L-threonine, etc., and achieve the effects of simple steps and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

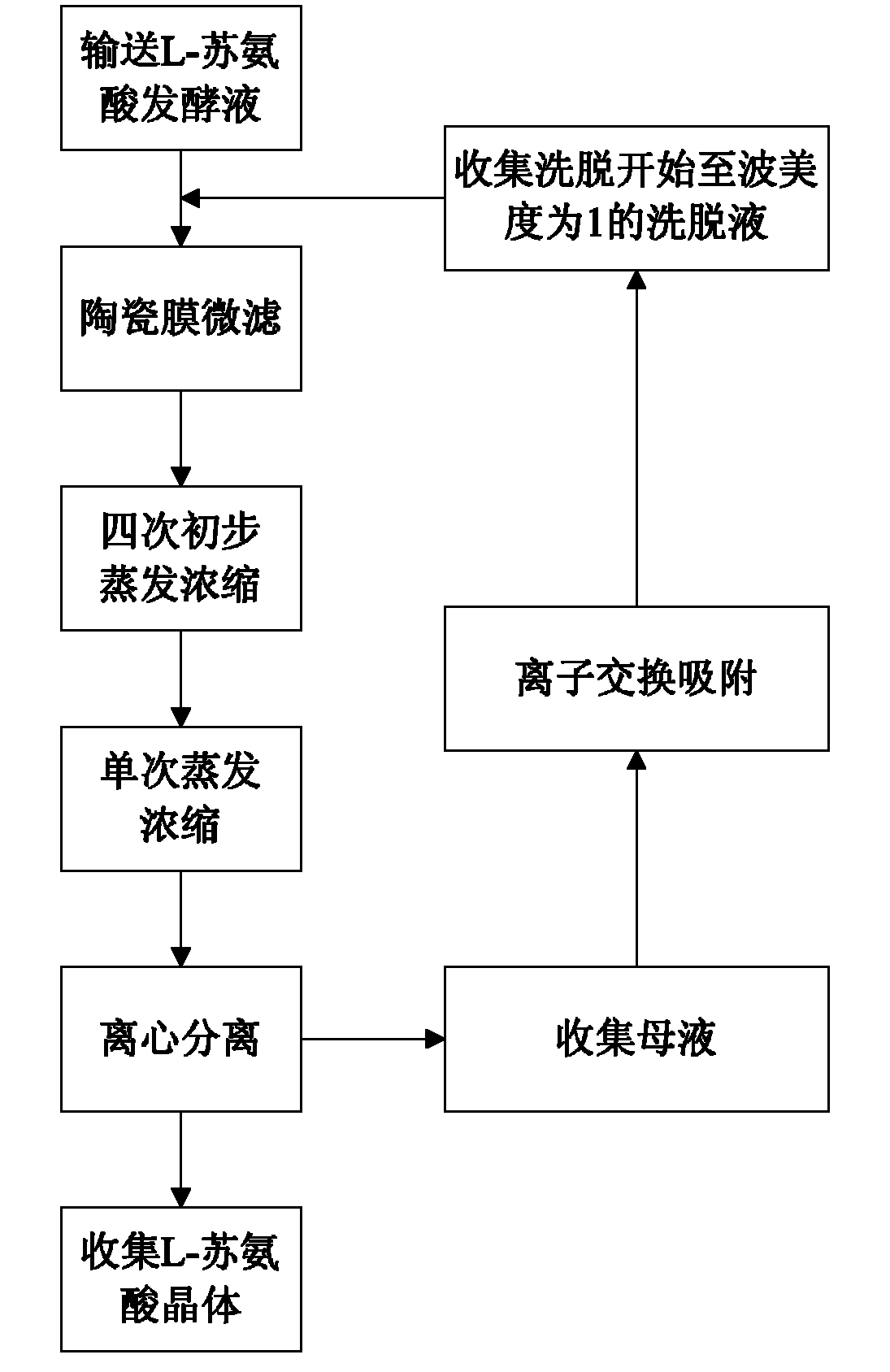

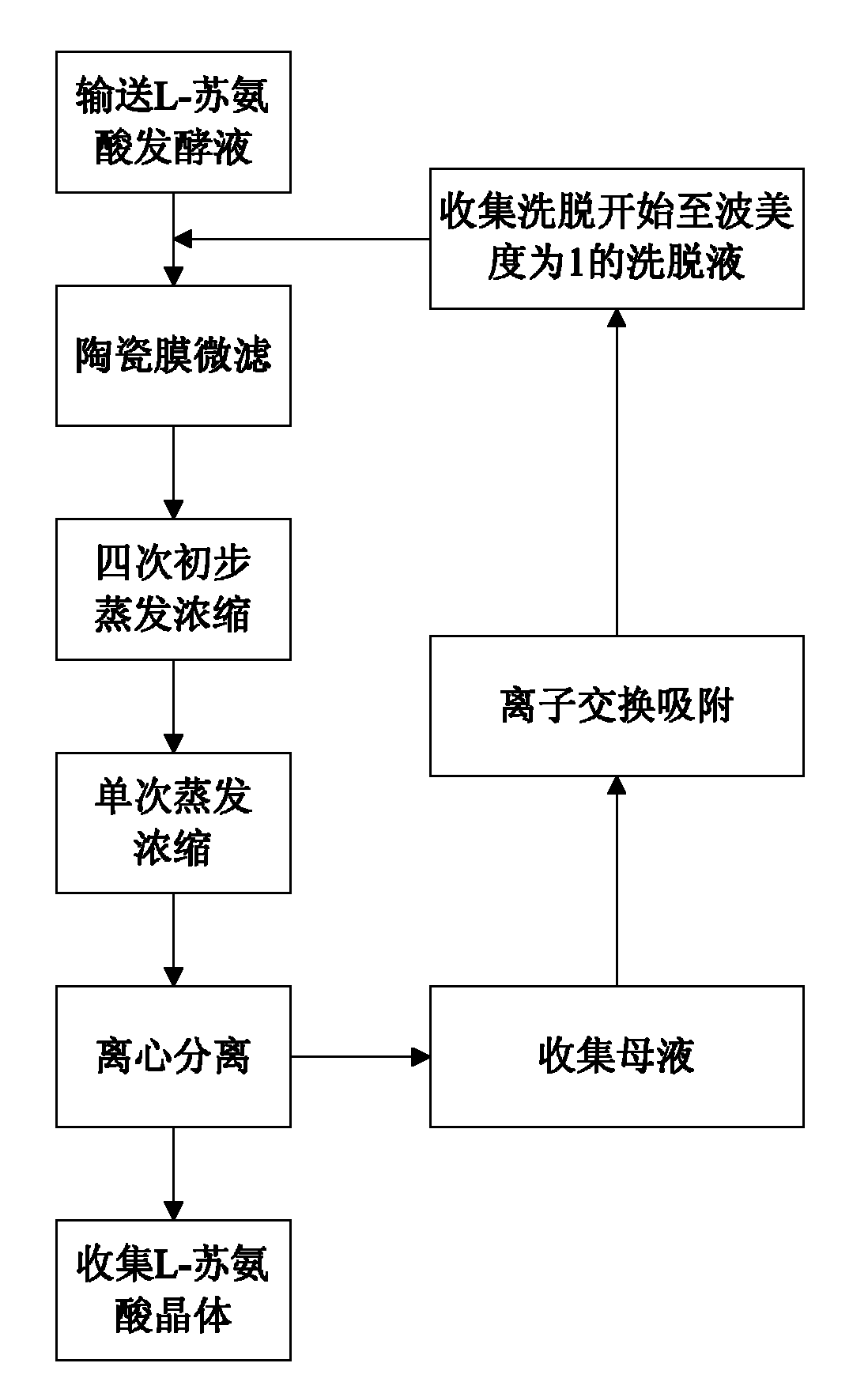

Image

Examples

Embodiment 1

[0032] Embodiment 1: the method for extracting L-threonine described in the present invention

[0033] 1. Extraction method

[0034] The L-threonine fermentation broth is sterilized and filtered through a ceramic membrane. The ceramic membrane has a pore size of 50nm, a molecular weight of 30KD, an operating pressure of 1.5bar, a transmembrane pressure difference of 1bar, and a temperature of 25°C. The volume ratio of the fermentation broth is 1:4.

[0035] The obtained L-threonine filtrate enters the four-effect evaporation for preliminary concentration, the vacuum degree is controlled at -0.092Mpa, the temperature is respectively controlled at 50°C, 60°C, 70°C, and 80°C, and the Baume concentration of the filtrate is finally controlled to reach 7, Then enter the single-effect evaporator for further concentration, control the temperature at 55°C, control the vacuum degree at -0.092Mpa, stir at 80rpm, concentrate until the solid-liquid ratio of the filtrate reaches 0.45:1, pu...

Embodiment 2

[0039] Embodiment 2: the method for extracting L-threonine described in the present invention

[0040] 1. Extraction method

[0041] The L-threonine fermentation broth is sterilized and filtered through a ceramic membrane. The ceramic membrane has a pore size of 50nm, a molecular weight of 30KD, an operating pressure of 1.5bar, a transmembrane pressure difference of 1bar, and a temperature of 25°C. The volume ratio of the fermentation broth is 1:6.

[0042] The obtained L-threonine filtrate enters the four-effect evaporation for preliminary concentration, the vacuum degree is controlled at -0.092Mpa, the temperature is respectively controlled at 50°C, 60°C, 70°C, and 80°C, and the Baume concentration of the filtrate is finally controlled to reach 8, Then enter the single-effect evaporator for further concentration, control the temperature at 58°C, control the vacuum degree at -0.092Mpa, stir at 80rpm, concentrate until the solid-liquid ratio of the filtrate reaches 0.75:1, put ...

Embodiment 3

[0046] Embodiment 3: the method for extracting L-threonine described in the present invention

[0047] 1. Extraction method

[0048] The L-threonine fermentation broth is sterilized and filtered through a ceramic membrane. The ceramic membrane has a pore size of 50nm, a molecular weight of 30KD, an operating pressure of 1.5bar, a transmembrane pressure difference of 1bar, and a temperature of 25°C. The volume ratio of the fermentation broth is 1:5.

[0049] The obtained L-threonine filtrate enters the four-effect evaporation for preliminary concentration, the vacuum degree is controlled at -0.092Mpa, the temperature is respectively controlled at 50°C, 60°C, 70°C, and 80°C, and the Baume concentration of the filtrate is finally controlled to reach 9, Then enter the single-effect evaporator for further concentration, control the temperature at 57°C, control the vacuum degree at -0.092Mpa, stir at 80rpm, concentrate until the solid-liquid ratio of the filtrate reaches 0.6:1, put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com