Method for union modification of wood by treating cell walls through silicon-containing compound and filling cell cavities with polymer

A silicon compound and cell wall technology, applied in wood impregnation, impregnated wood, wood processing utensils, etc., can solve the problems that are difficult to improve the mechanical properties and durability of wood at the same time, and achieve excellent mechanical properties and dimensional stability, high thermal stability, Effect of improving mechanical properties and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

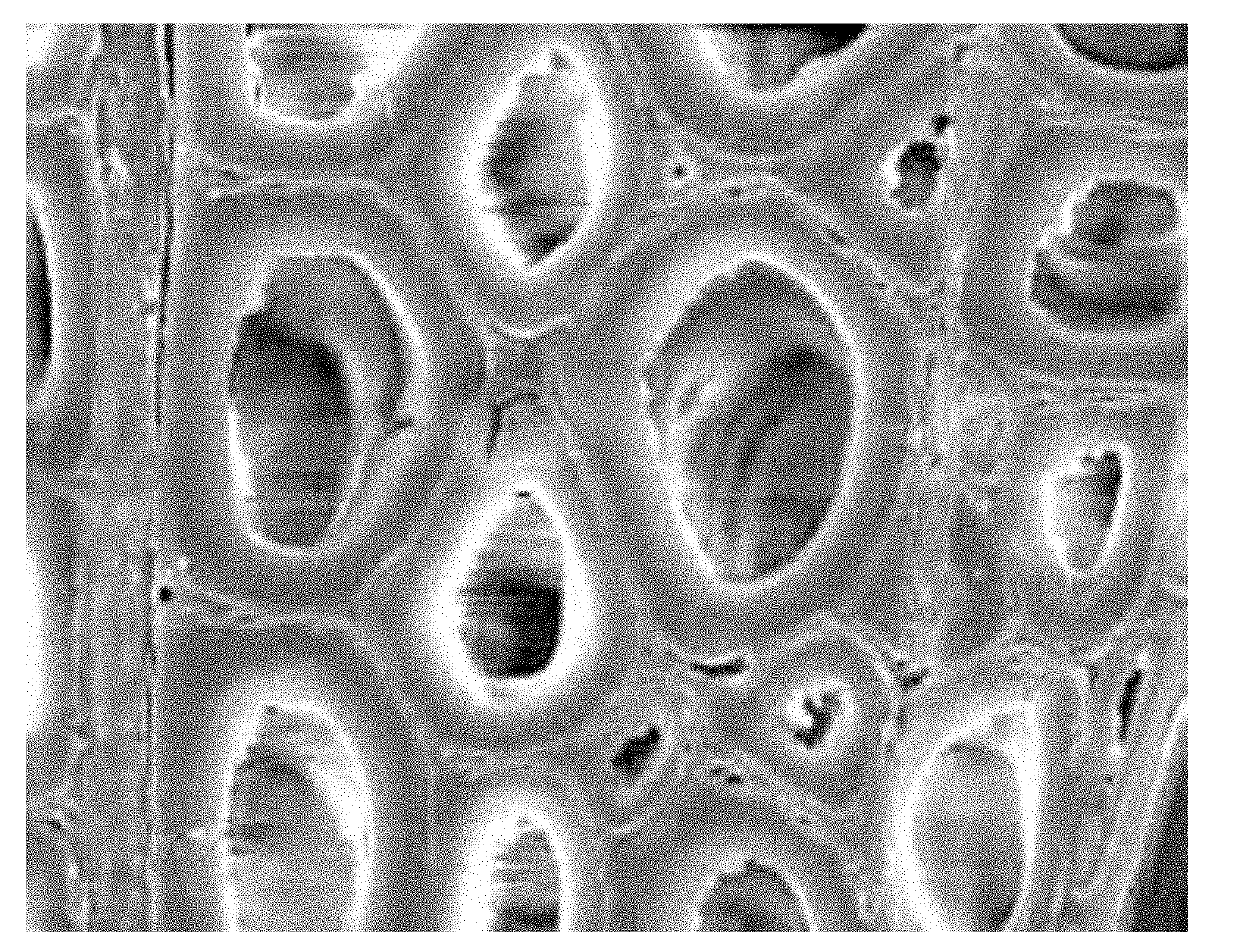

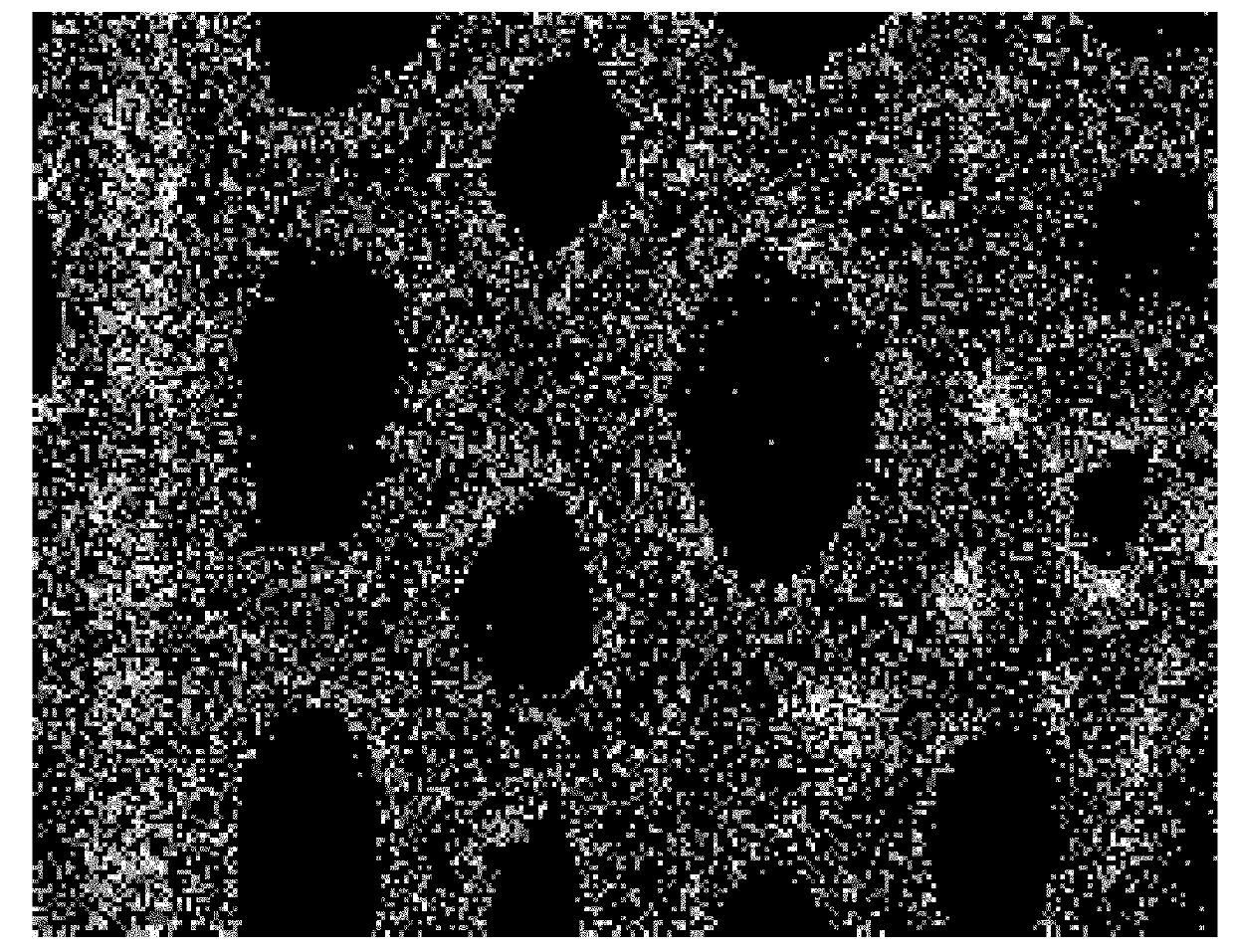

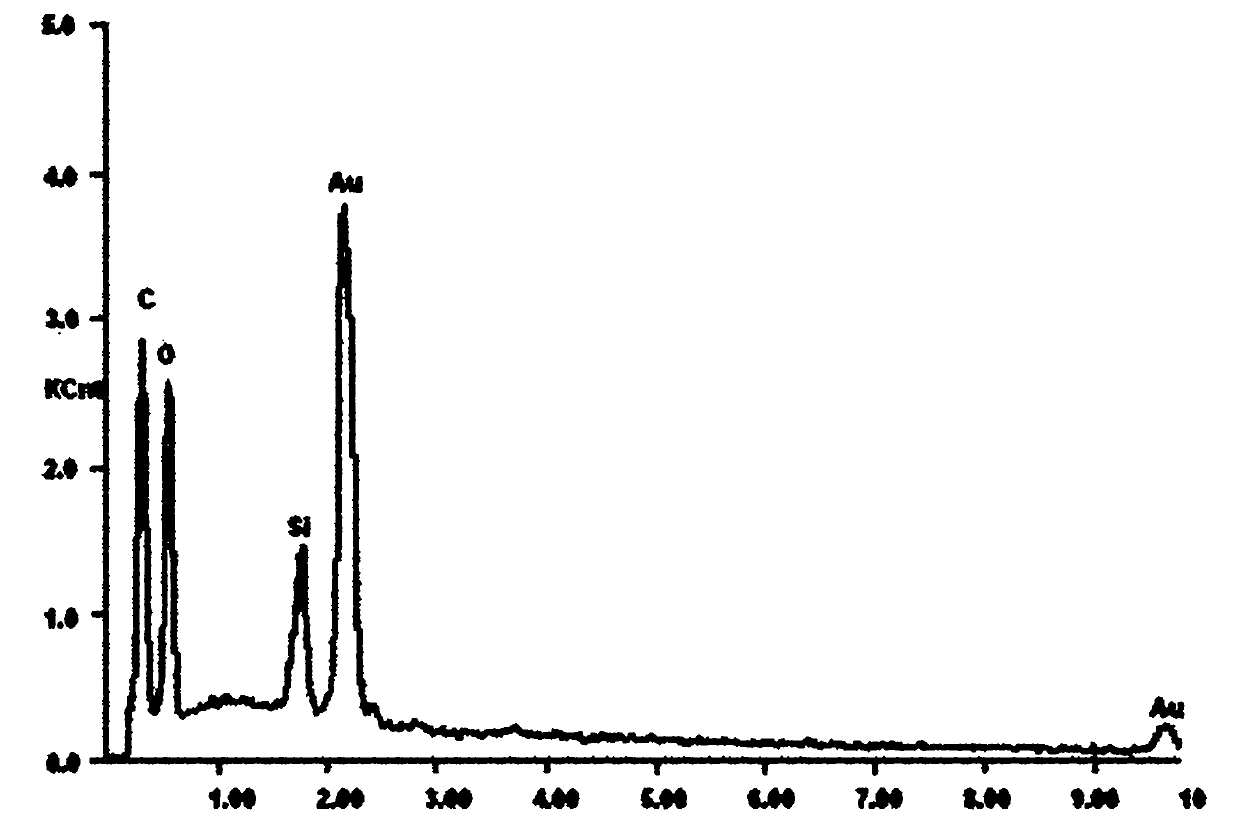

[0012] Embodiment 1: In this embodiment, the method of using silicon-containing compounds to treat cell walls and polymers to fill cell lumens to jointly modify wood is as follows: 1. Pre-humidity of wood: placing wood at a humidity of 20% to 98% Leave it for 1 to 3 months in the environment to obtain wood with a moisture content of ≤30% in the wood cell wall; 2. The configuration of the silicon-containing precursor solution: mix ethyl orthosilicate, absolute ethanol and silane coupling agent in moles The ratio is 1:4:0.1, and then add acid to adjust the pH value to 4.5-5.5 to obtain the silicon-containing precursor solution; 3. The impregnation of the wood with the silicon-containing precursor solution: after the first step The wood was immersed in the silicon-containing precursor solution, vacuumed for 30 minutes under the condition of vacuum degree of -0.08MPa, and then pressurized for 30 minutes under the pressure of 0.8MPa, and the normal pressure was restored. The wood wa...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that the acid described in step 2 is hydrochloric acid or acetic acid. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment is different from Embodiment 1 in that the pH value is adjusted to 5.0 in step 2. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com