Chemical mechanical polishing system

A technology of chemical machinery and polishing device, which is applied in the field of chemical mechanical polishing system, can solve the problems of a lot of time and energy spent on shutdown maintenance, troublesome CMP process monitoring, and affecting production efficiency, so as to reduce the probability of scratches, improve production efficiency, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

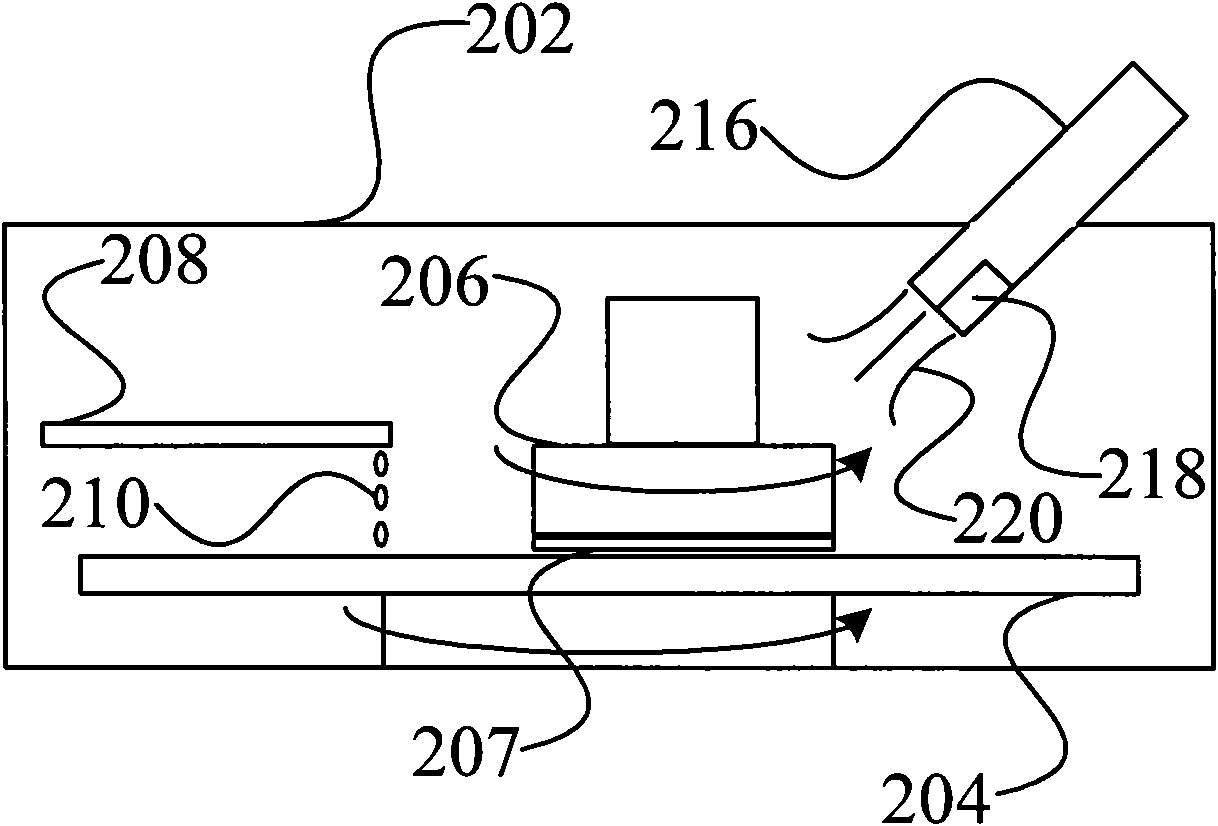

[0021] image 3 It is a schematic diagram of a chemical mechanical polishing system according to an embodiment of the present invention. Such as image 3 As shown, the chemical mechanical polishing system includes an outer cover 202 , a chemical mechanical polishing device inside the outer cover 202 , and an ultrasonic sprayer 216 for spraying into the outer cover 202 .

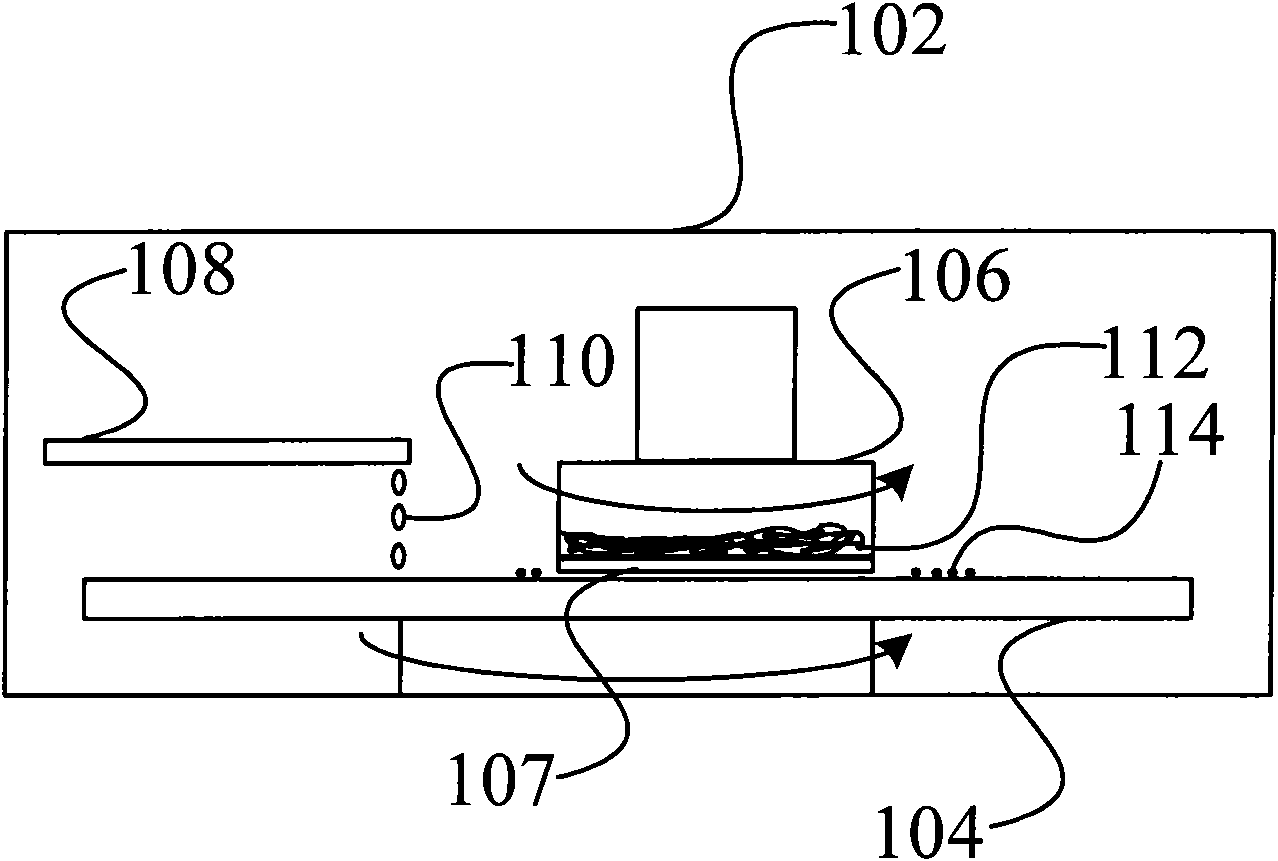

[0022] In this embodiment, the chemical mechanical polishing device includes a rotatable grinding pad 204; a grinding head 206 that turns to the same direction as the grinding pad 204, and a wafer 207 is adsorbed on the grinding head 206 by vacuum suction; The delivery pipe 208 for dripping the polishing liquid 210 onto the surface of the polishing pad 204 .

[0023] In this embodiment, the chemica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com