Rear stop mechanism of plate shearing machine

A technology of backgauge and shearing machine, which is applied in the field of sheet metal processing, can solve the problems of backgauge deformation, backgauge error, and shear sheet size error, etc., and achieve the effect of strengthening the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

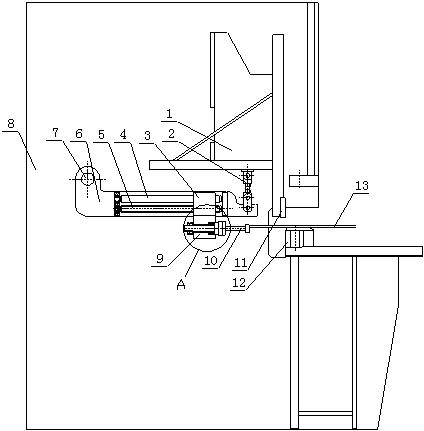

[0016] Such as figure 1 , 2 As shown, it is the back gauge mechanism of the shearing machine, including wallboard 8 and knife rest 1, a support shaft 7 is connected on the wallboard 8, a connecting rod 2 is connected below the knife rest 1, and the lower end of the connecting rod 2 can be The bracket 6 is detachably connected, and the other end of the bracket 6 is hingedly connected with the support shaft 7 . The light rod 4 and the lead screw 5 are arranged on the support 6 through bearings, the light rod 4 and the lead screw 5 are arranged in parallel, the lead screw 5 is screwed to the slide seat 3, the slide seat 3 is set outside the light rod 4, and the slide seat 3 is fixedly connected Hang tight seat 9, and hang tight seat 9 and connect material retaining plate 10. Among the figure, 11 is an upper blade, 12 is a lower blade, and 13 is a processing plate.

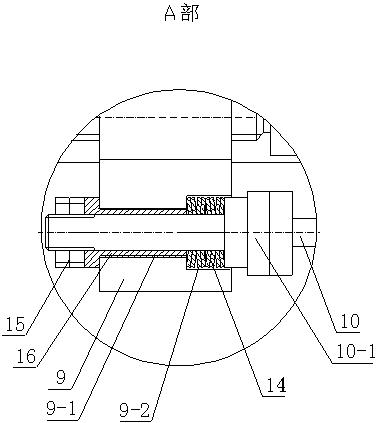

[0017] Such as image 3 As shown, an outwardly protruding step 10-1 is set on the baffle plate 10, a groove 9-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com