Method for processing high-pulp content and concentrated lime juice

A technology of lime juice and high pulp, applied in food science and other directions, can solve the problems of single extraction component, immature production technology, serious secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

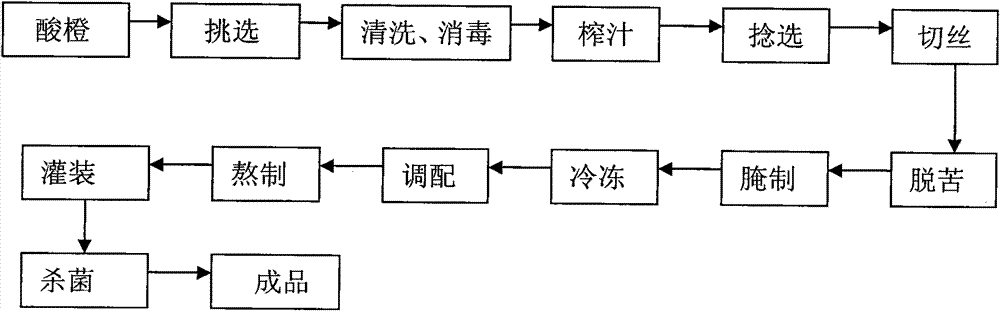

[0028] Embodiment 1 basic process

[0029] A kind of processing method of concentrated lime juice, its steps are as follows:

[0030] 1) choose the sour orange fruit with 90% maturity and consistent maturity, no disease in fruit appearance, and no mechanical damage as raw material for processing;

[0031] 2) Soak the sour orange fruit to be treated in a potassium permanganate solution of 0.1-0.2% concentration for 5-10 minutes, then spray the surface of the fruit with chlorinated water of 10-30 mg / l for sterilization, Finally, spray with clear water to obtain clean fruit;

[0032] 3) Squeeze the cleaned fruit of step 2) with a centrifugal juicer, filter or centrifuge, and collect lime juice and pomace;

[0033] 4) Shred the skin residue of step 3), its width is 3mm;

[0034] 5) The lime juice was eluted with macroporous resin HDP800 to debitterize it, and the skin dregs were soaked for 15 minutes according to the ratio of volume to mass of water and skin dregs of 8:1 to deb...

Embodiment 2

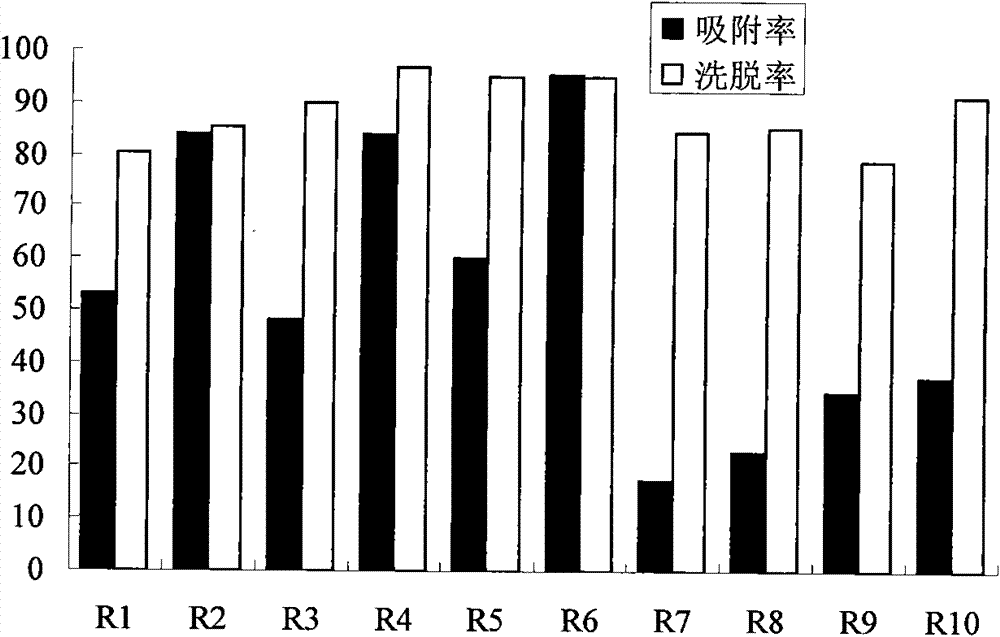

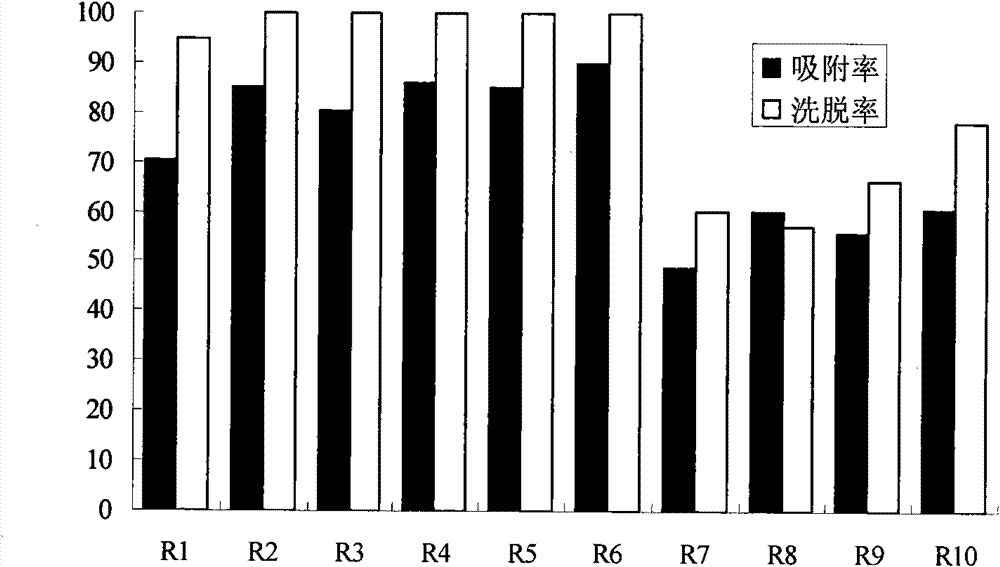

[0038] Embodiment 2: Debittering experiment of lime juice macroporous resin

[0039] 1. Test material

[0040] Lime juice: squeeze the ripe lime juice, filter it, centrifuge at 4200r / min for 15min, and store it frozen for later use. The soluble solid content of the lime juice is 10.6°Brix. Macroporous adsorption resin (models are D3520, D7040, DA201, D1400, AB-8, products of Tianjin Nankai University Chemical Factory; HDP800, products of Hebei Cangzhou Baoen Chemical Co., Ltd.), ion exchange resins (D151, D152, JK- 110, D3P2R, product of Tianjin Nankai University Chemical Plant). The physical and chemical properties of different resins are listed in Table 1.

[0041] Table 1 Physical and chemical properties of different resins

[0042]

[0043] 2. Resin pretreatment

[0044] First soak in 2VB 5% HCL solution for 2 hours, wash with distilled water until neutral, soak in 2VB 5% NaOH for 2 hours, distill water until neutral, then wash with 3VB 95% ethanol, wash with distille...

Embodiment 3

[0062] Example 3 Effects of Different Pretreatments and Freezing Storage on the Characteristics of Lime Slices

[0063] 1. Test material: Lime, collected from the citrus base of Hubei Wangchunhua Juice Co., Ltd.

[0064] After picking limes with uniform size and maturity and removing the outer layer of oil, separate the lime peel, pick the lime peel with uniform thickness, and cut it into lime slices with a thickness of 3mm. , 1% Ca 2+ Soaking, according to the mass ratio of white sugar and lime peel 1:1, sugar pickled,) lime shreds and untreated lime slices were stored in freezing conditions (-18°C) and normal temperature (10-15°C) respectively. , at regular intervals, the crispness, PG activity, and SP content of different pretreated lime slices were measured during storage.

[0065] 2. Determination of enzyme activity

[0066] Determination of galacturonidase (PG) enzyme activity: Weigh 10.00g lime peel, grind under cold bath conditions, add pre-cooled 20ml extract (0.2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com