Insulating cover for solid insulating fully sealed switch

A technology of solid insulation and insulating cover, which is used in electrical switches, high-voltage/high-current switches, substations/switchgear boards/panels/desks, etc. problem, to achieve the effect of compact size, simple and convenient connection, and enhanced insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

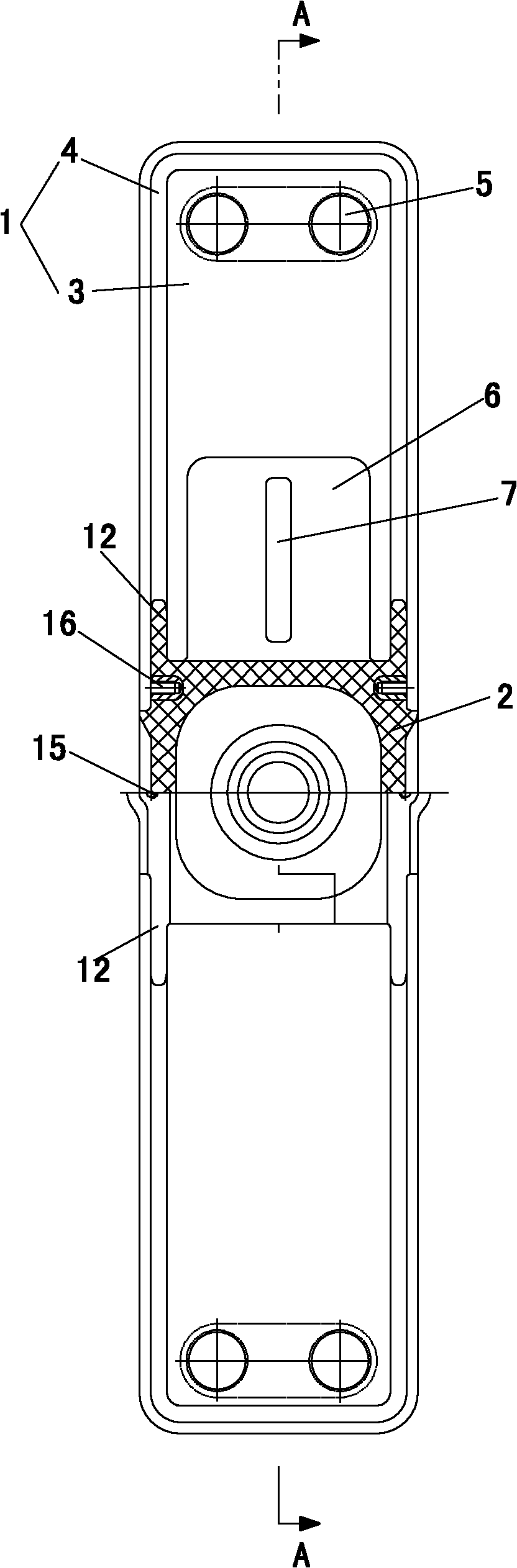

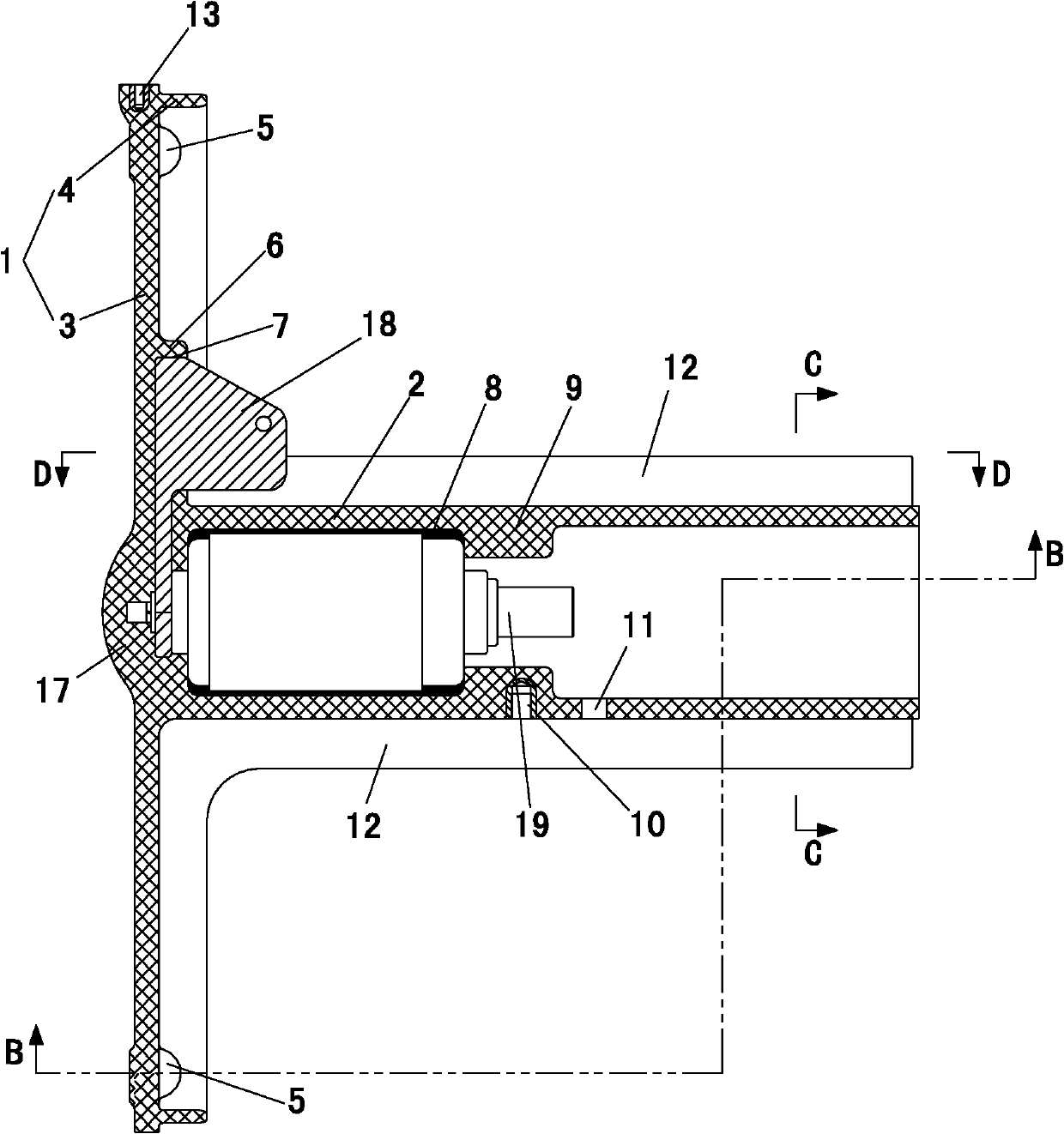

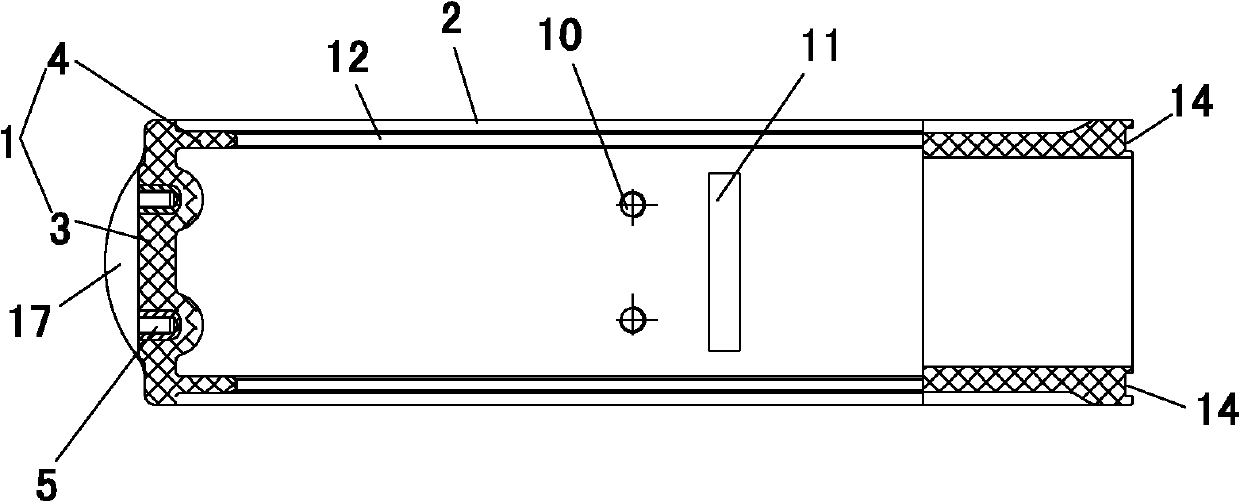

[0016] Such as Figure 1 to Figure 7 As shown, the insulating cover of the solid insulation fully sealed switch of the present invention is a T-shaped cover body composed of a rectangular cover 1 and a square cylindrical vacuum blister sleeve 2, and the cover body is made of purple-red epoxy resin material;

[0017] The cover 1 is integrally composed of a cover plate 3 and a protruding first pin 4 around the front end of the cover plate 3. A convex circle 17 is provided in the center of the back of the cover plate 3. The surface of the cover plate 3 is provided with four holes for connecting with the back of the switch cabinet. The first insert threaded hole 5 for board connection, the upper and lower end surfaces of the cover plate 3 are respectively provided with a second insert threaded hole 13 for connecting with the switch cabinet, and a rectangular protrusion is provided in the middle of the front surface of the cover plate 3 6. The vacuum blister sleeve 2 is vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com