Method for online analysis of water content of solid master batch recovery system in aromatic acid production

The technology of a recovery system and an analysis method is applied in the field of on-line moisture analysis of the mother solid material recovery system in the production of aromatic acids, which can solve the problems of inability to realize automatic operation of the device, complex water quality components, and high labor intensity, and achieve reliable moisture measurement results, Short response time and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

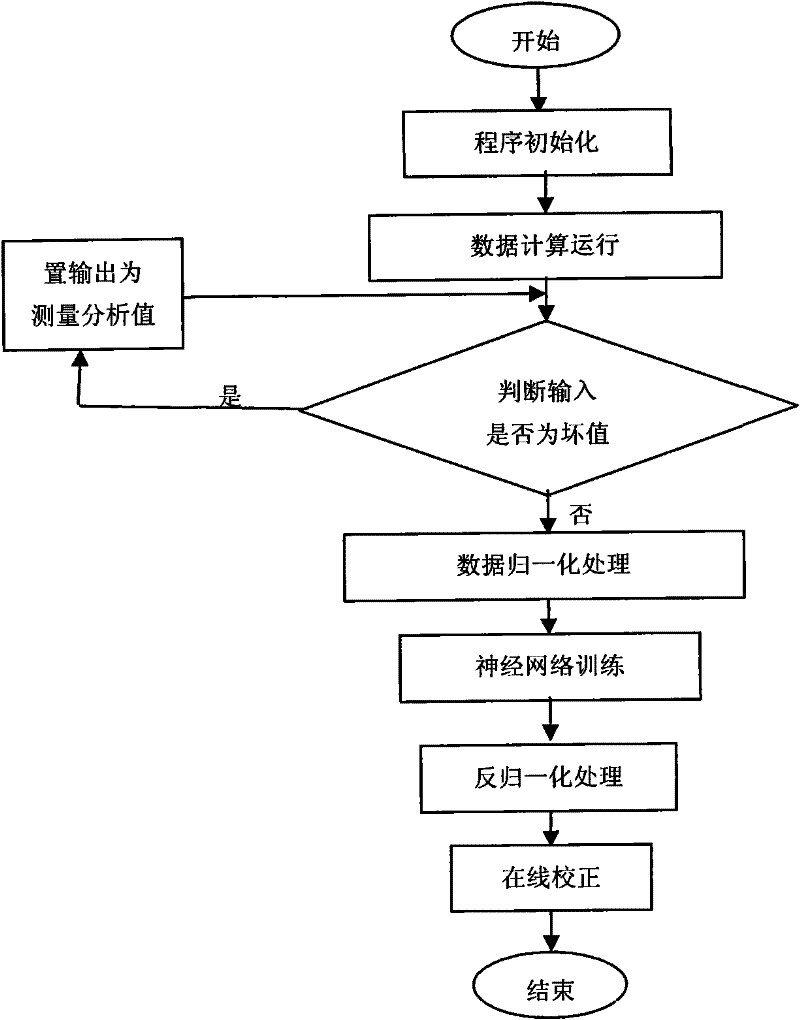

[0038] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

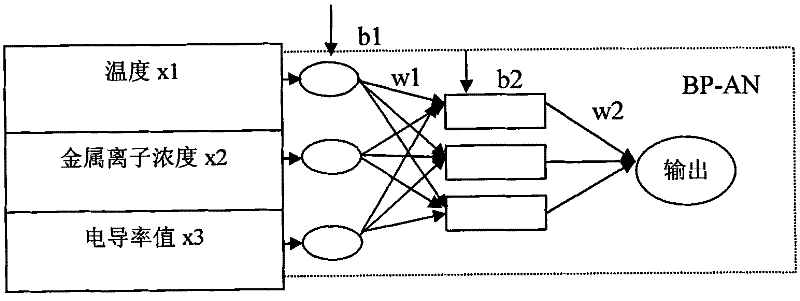

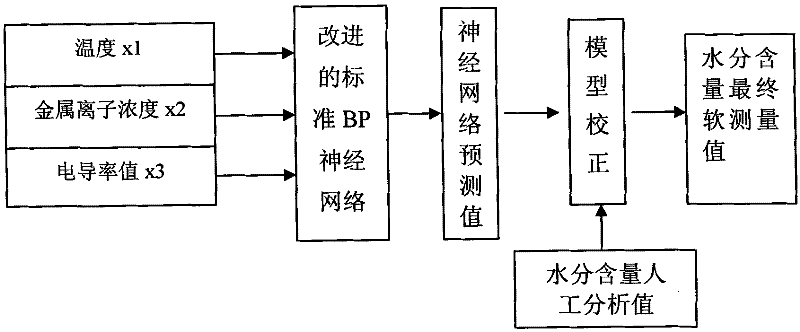

[0039] Establishment of moisture content BP neural network model:

[0040]Feed-forward neural network (BP model) is the most researched and most used network model in the field of neural network. Its nonlinear approximation capabilities are the main reason for its popularity. But the BP algorithm also has some defects, mainly the uncertainty of its training process. The specific performance is: for some complex problems, because the learning rate is too small, the BP algorithm may need to be trained for several hours or even longer. Many people have proposed many improved algorithms for the shortcomings of the gradient descent method, such as the second-order fast BP algorithm, the momentum factor method, and the action function adjustment method. Compared with the gradient descent method, these improved methods have significantly improved convergence spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com