Intelligent vaporization method of vaporized petroleum liquid and equipment thereof

An intelligent, petroleum-based technology, applied in combustion methods, liquid fuel supply/distribution, etc., can solve problems such as complex equipment structure, difficulty in standardized production and installation, unstable gas supply pressure, etc., and reduce equipment manufacturing and installation costs , better energy-saving effect, adjustable and controllable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

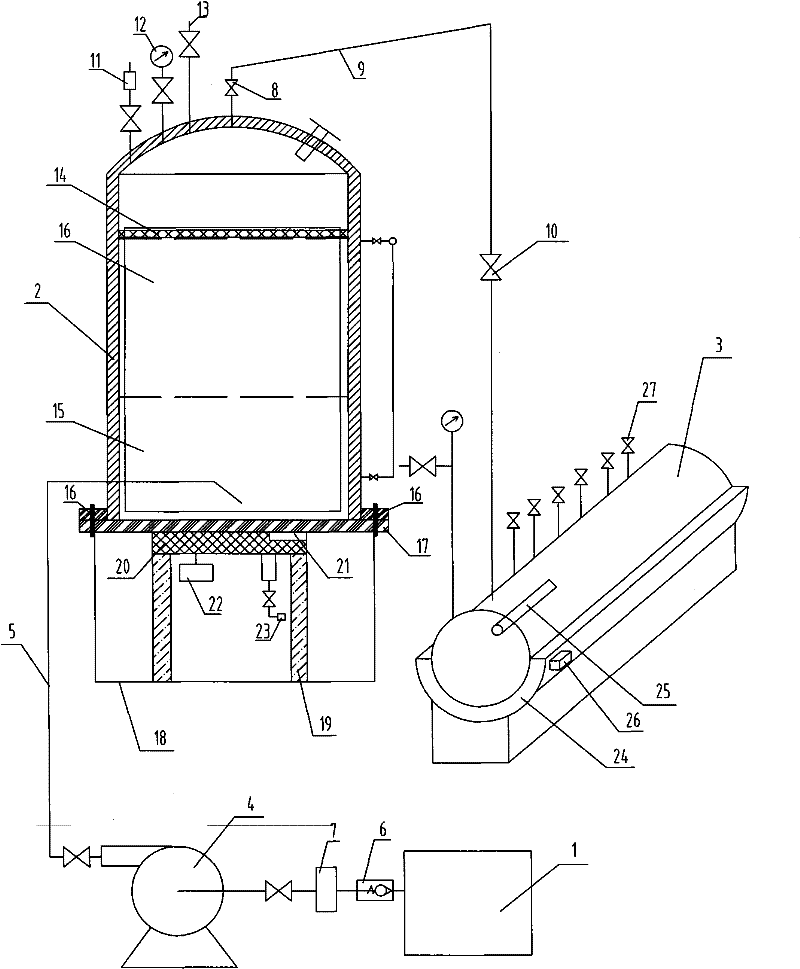

[0029] The intelligent vaporized petroleum liquid vaporization equipment of this embodiment has a structure such as figure 1 As shown, it includes a reserve cylinder 1, a vaporization tank 2 and a gas collecting pipe 3. The reserve cylinder 1 and the vaporization tank 2 are connected through a filling pipe 5 provided with a high-pressure liquid filling pump 4. The reserve cylinder 1 is connected through a one-way valve 6 and a filter Device 7 is connected with high-pressure filling pump 4. The vaporization tank 2 and the gas collecting pipe 3 are connected through a main air pipe 9 connected with an air supply valve 8 , and the gas supply valve 8 is connected with the gas collecting pipe 3 through an adjustable pressure reducing and stabilizing valve 10 . The upper part of the vaporization tank 2 is connected with a pressure sensor 11 , a pressure gauge 12 and an overpressure vent pipe 13 , and an anti-foaming net 14 is arranged at the upper part of the vaporization tank 2 . ...

Embodiment 2

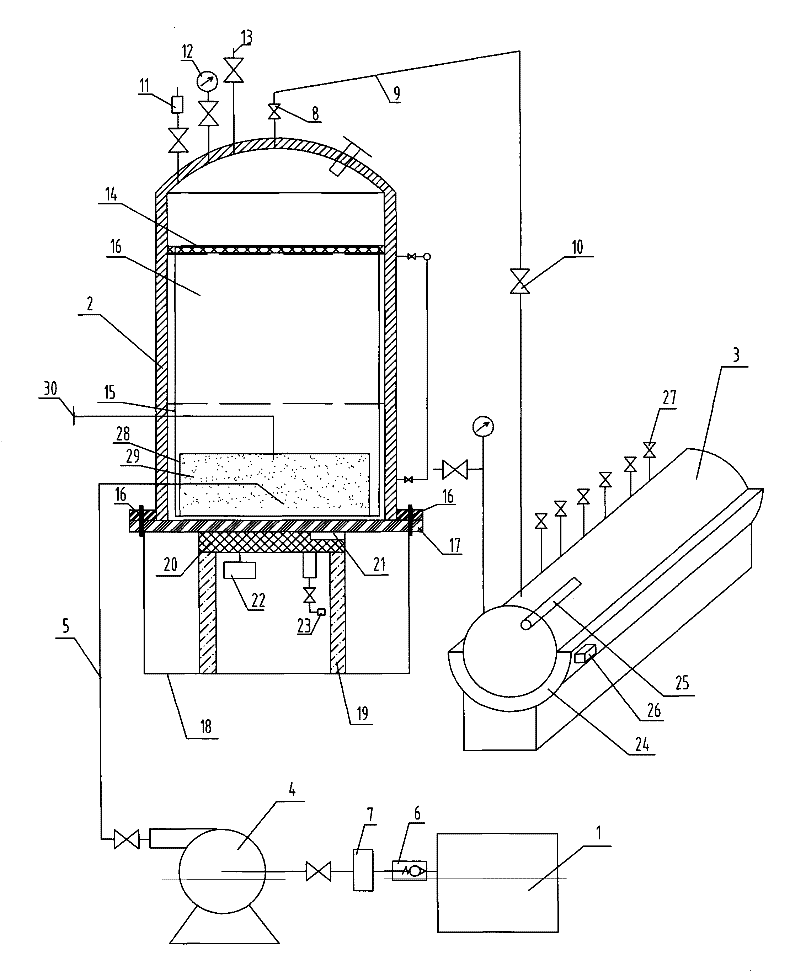

[0039] The intelligent vaporized petroleum liquid vaporization equipment of this embodiment has a structure such as figure 2 As shown, it includes a reserve cylinder 1, a vaporization tank 2 and a gas collecting pipe 3. The reserve cylinder 1 and the vaporization tank 2 are connected through a filling pipe 5 provided with a high-pressure liquid filling pump 4. The reserve cylinder 1 is connected through a one-way valve 6 and a filter Device 7 is connected with high-pressure filling pump 4. The vaporization tank 2 and the gas collecting pipe 3 are connected through a main air pipe 9 connected with an air supply valve 8 , and the gas supply valve 8 is connected with the gas collecting pipe 3 through an adjustable pressure reducing and stabilizing valve 10 . The upper part of the vaporization tank 2 is connected with a pressure sensor 11 , a pressure gauge 12 and an overpressure vent pipe 13 , and an anti-foaming net 14 is arranged at the upper part of the vaporization tank 2 . ...

Embodiment 3

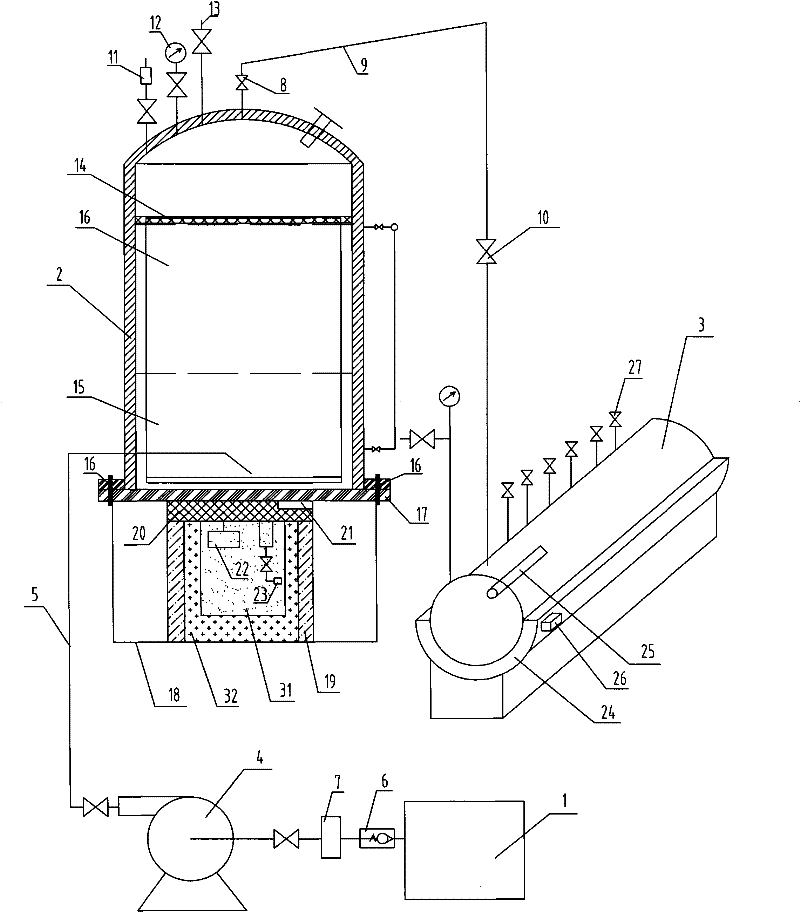

[0050] The intelligent vaporized petroleum liquid vaporization equipment of this embodiment has a structure such as figure 2 As shown, it includes a reserve cylinder 1, a vaporization tank 2 and a gas collecting pipe 3. The reserve cylinder 1 and the vaporization tank 2 are connected through a filling pipe 5 provided with a high-pressure liquid filling pump 4. The reserve cylinder 1 is connected through a one-way valve 6 and a filter Device 7 is connected with high-pressure filling pump 4. The vaporization tank 2 and the gas collecting pipe 3 are connected through a main air pipe 9 connected with an air supply valve 8 , and the gas supply valve 8 is connected with the gas collecting pipe 3 through an adjustable pressure reducing and stabilizing valve 10 . The upper part of the vaporization tank 2 is connected with a pressure sensor 11 , a pressure gauge 12 and an overpressure vent pipe 13 , and an anti-foaming net 14 is arranged at the upper part of the vaporization tank 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com