System and method for testing frosting property of empty bath type vaporizer

A characteristic test, vaporizer technology, applied in the direction of container filling method, container discharge method, pressure vessel, etc., can solve the problems of no access threshold, confusion, research and optimal design, etc., and achieve the increase of flow resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

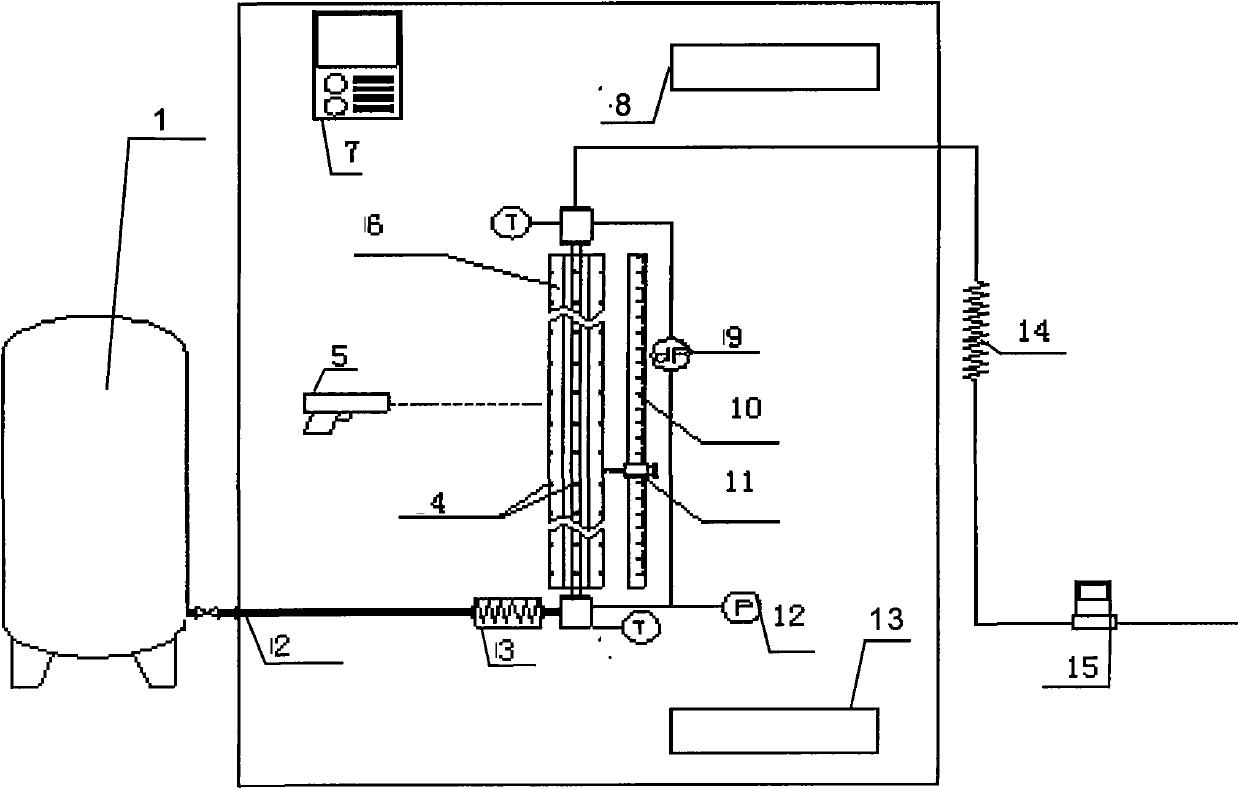

[0024] figure 1 Among them, 1 is a cryogenic liquid storage tank, 2 is a vacuum insulation tube, 3 is a subcooler, 4 is a T-type thermocouple temperature sensor, 5 is an infrared thermometer, 6 is a finned tube, and 7 is atmospheric pressure and temperature. Hygrometer, 8 is temperature control device, 9 is differential pressure transmitter, 10 is scale and bracket, 11 is digital micrometer, 12 is pressure transmitter, 13 is ultrasonic humidifier, 14 is vaporizer, 15 is gas Mass flowmeter.

[0025] The invention includes a cryogenic liquid storage tank, a vacuum insulated pipeline, a subcooler, a test section, a vaporizer, and the like. The liquid nitrogen is transported from the self-pressurized storage tank through the vacuum insulation tube to the subcooler for pre-cooling. After reaching a certain degree of subcooling, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com