Dust removal device for air filter cartridge

A technology of air filter element and dust removal device, applied in the direction of fuel air filter, etc., can solve the problems of time-consuming, labor-intensive, difficult to find, increase the operating cost of bus companies, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

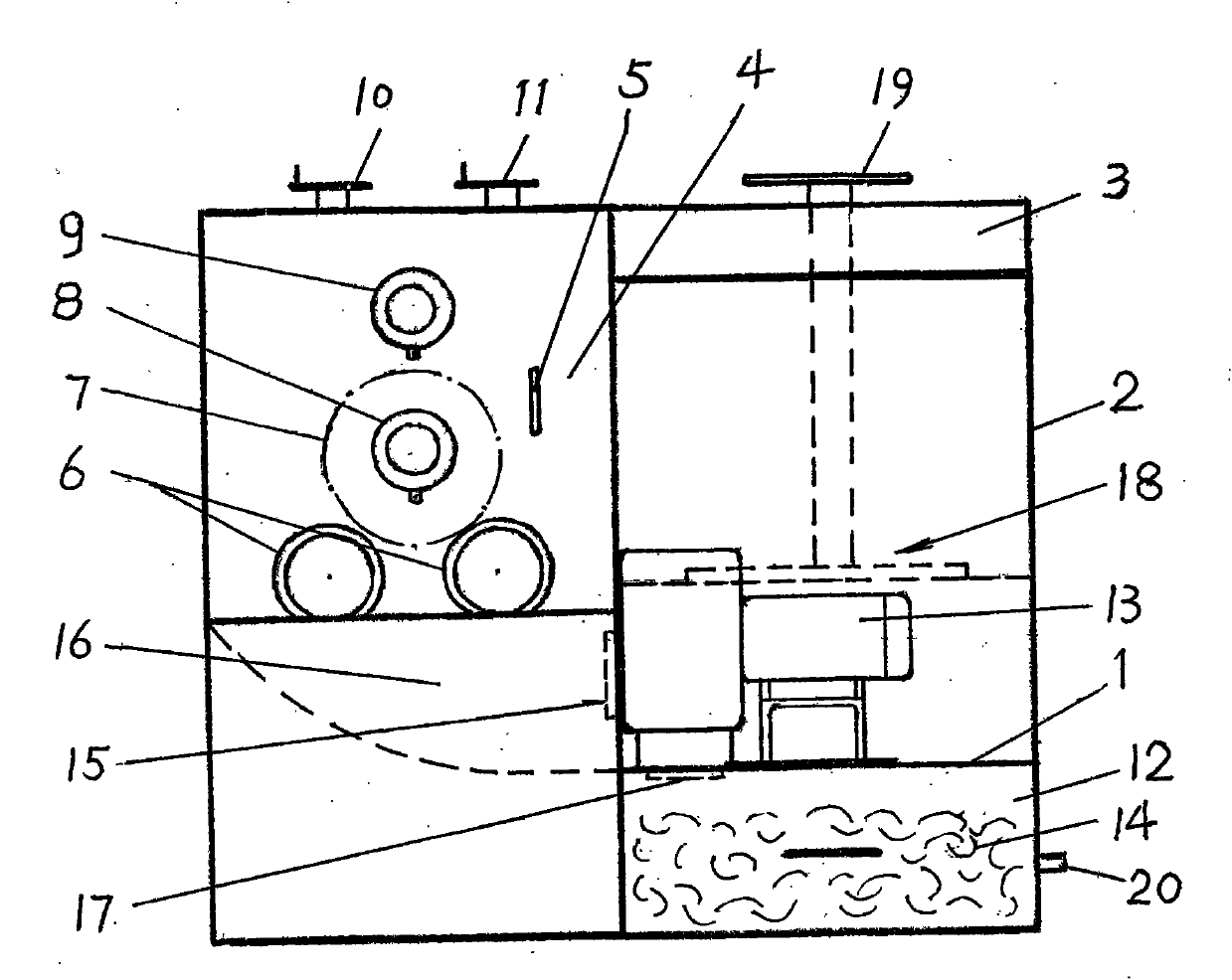

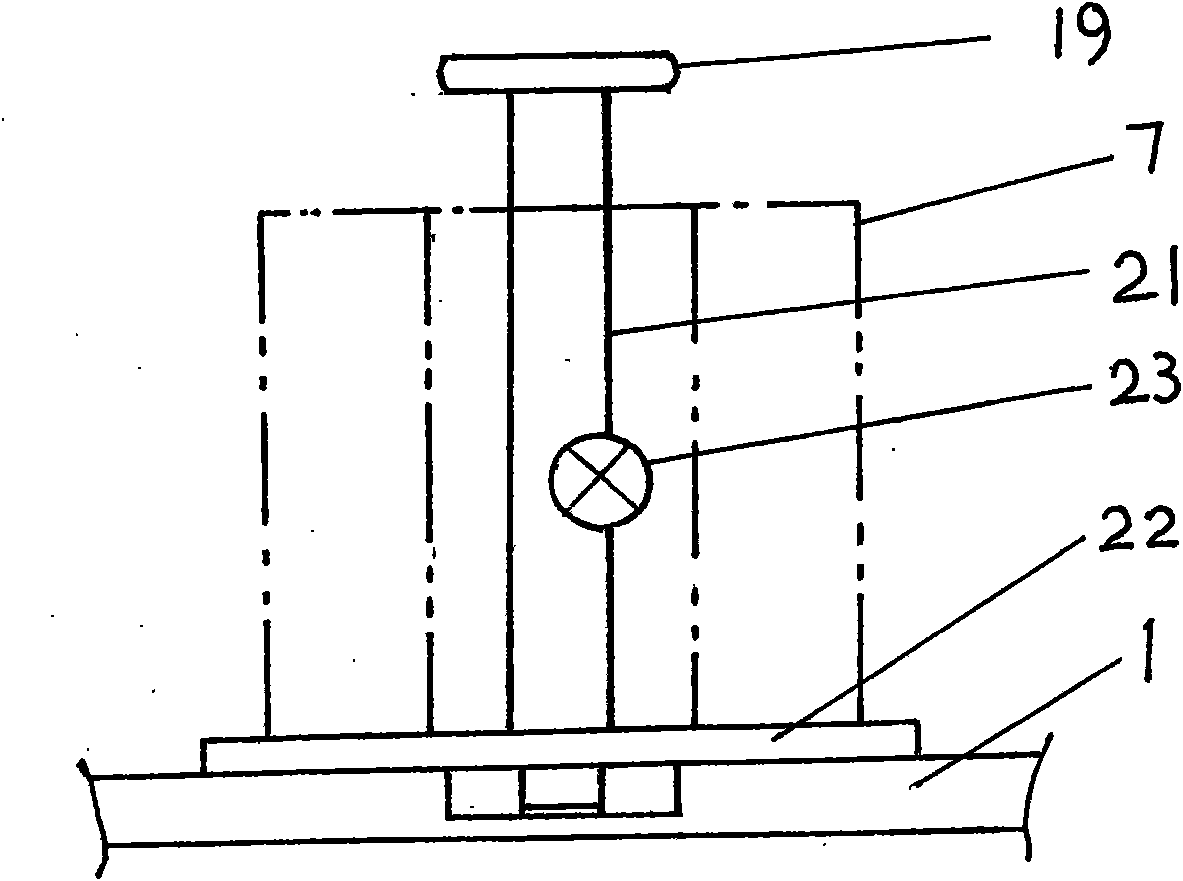

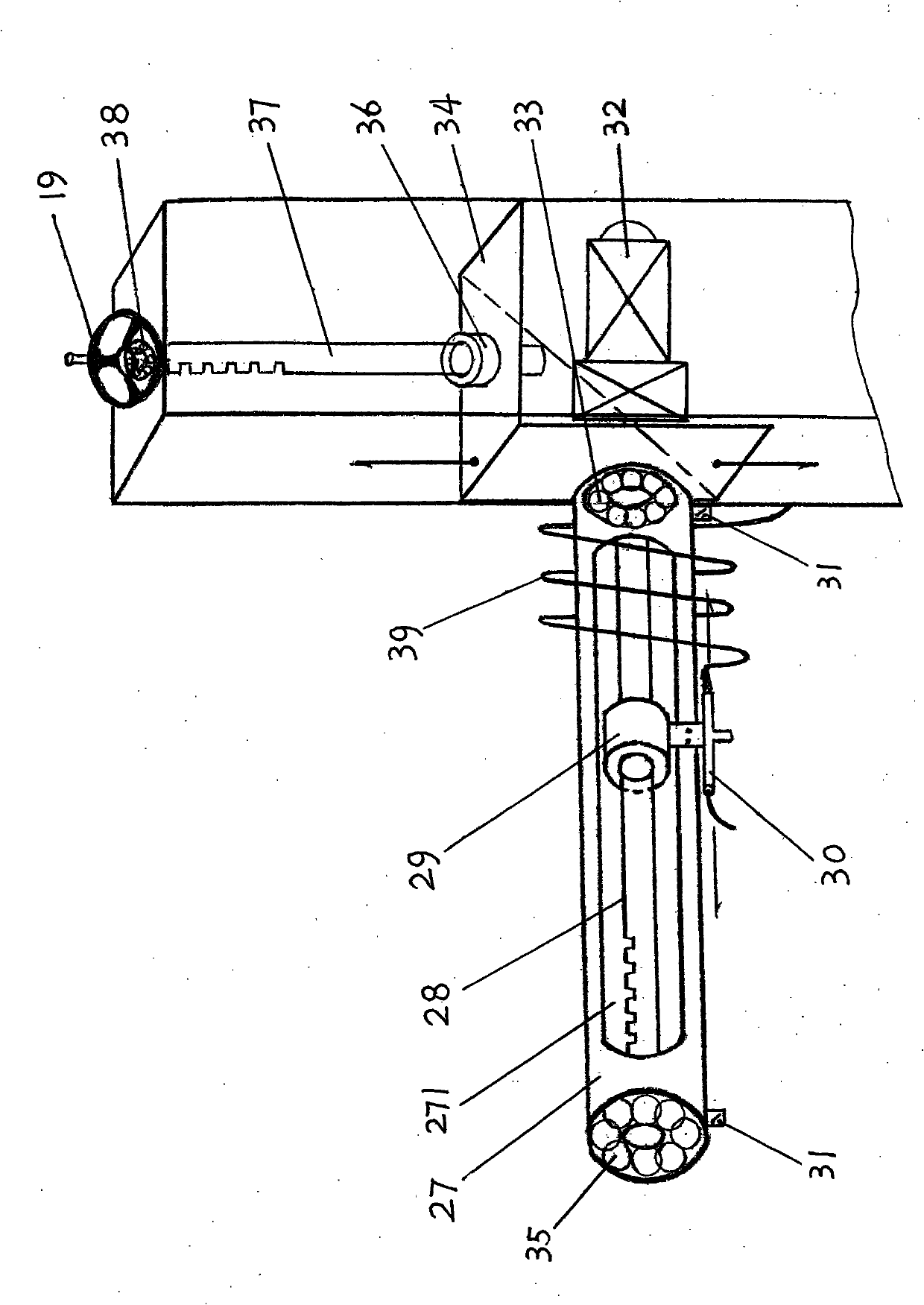

[0035]With reference to the accompanying drawings, it can be seen that the overall structure of the present invention is composed of the following components: 1--frame, 2--housing, 3--electric control panel, 4--the dust removal room with airtight structure, 5--the door handle of the dust removal room , 6--double roller (double roller) mechanism installed side by side horizontally, 7--the filter cartridge to be removed, 8-inner nozzle guide rod mechanism, 9-outer nozzle guide rod mechanism, 10--adjusting wheel (for manual type) Runner, used to adjust the inner nozzle guide rod mechanism), 11--adjusting wheel (manual runner, used to adjust the outer nozzle guide rod mechanism), 12--dust collection chamber (made into a drawer-type structure), 13 --vacuum pump, 14--water and coarse-pored sponge built in the dust collection chamber, 15--the air inlet (suction port) of the vacuum pump, 16-the chamber of the dust-falling area under the dust removal chamber, 17--the air outlet of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com