Trapped vortex tail wing carburetor of throttle

A technology of throttle valve and carburetor, which is applied in the field of throttle valve vortex tail carburetor, can solve the problems of combustion chamber intake pressure loss and other problems, and achieve the effect of small pressure loss and high mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

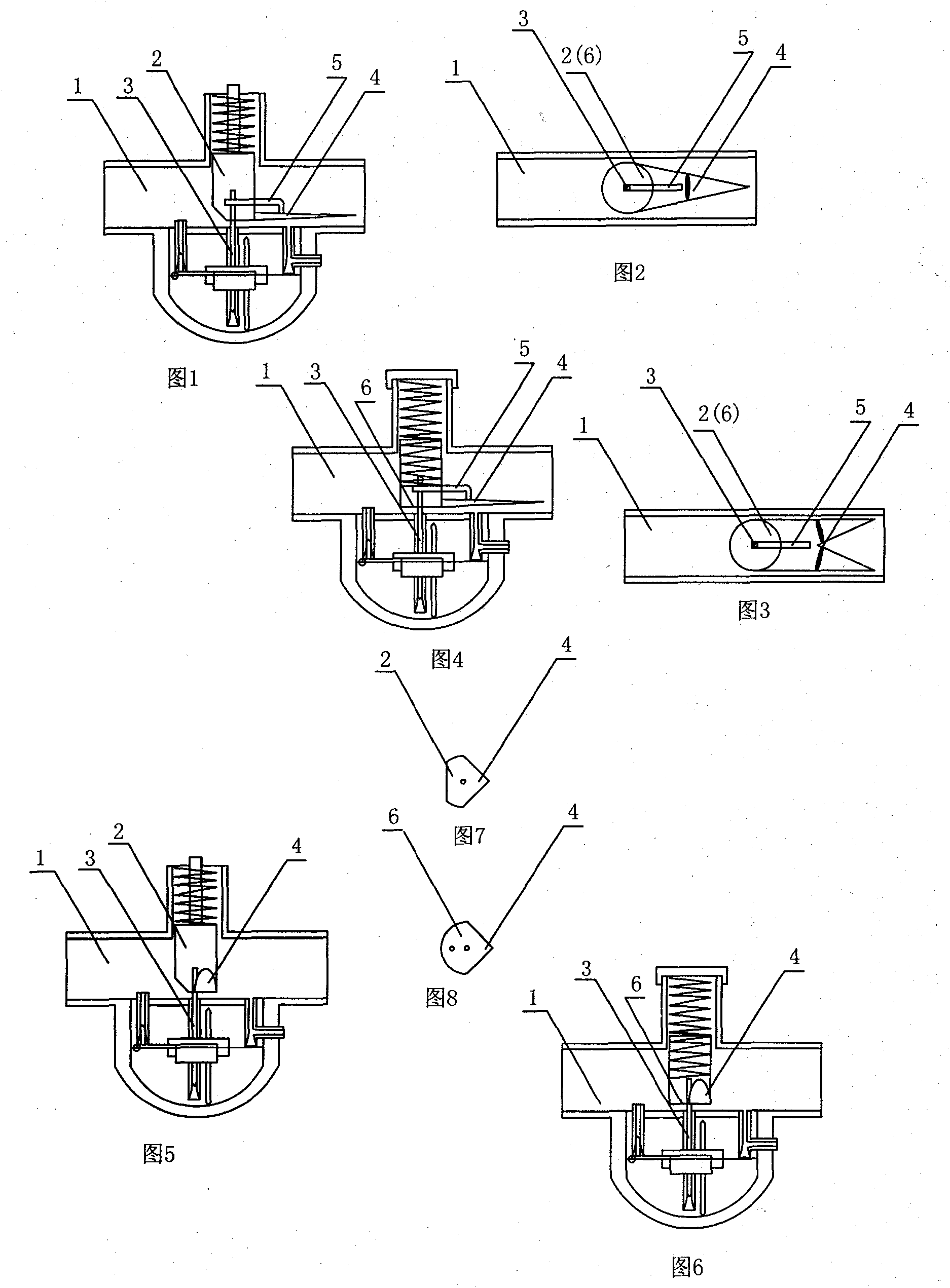

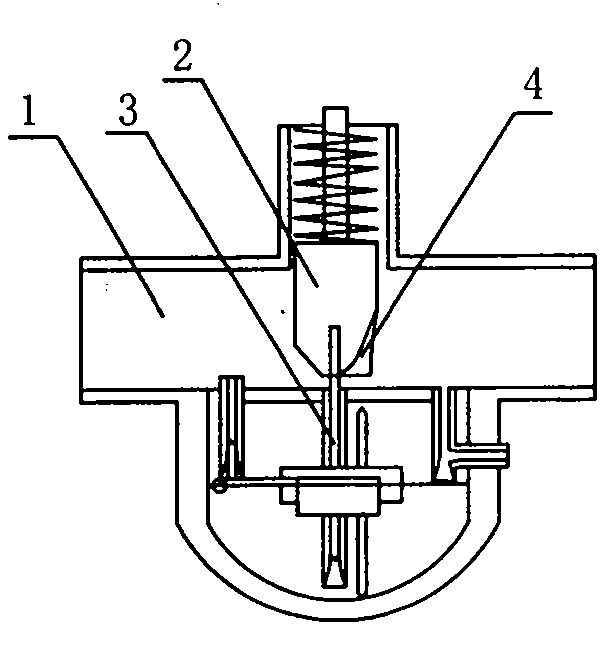

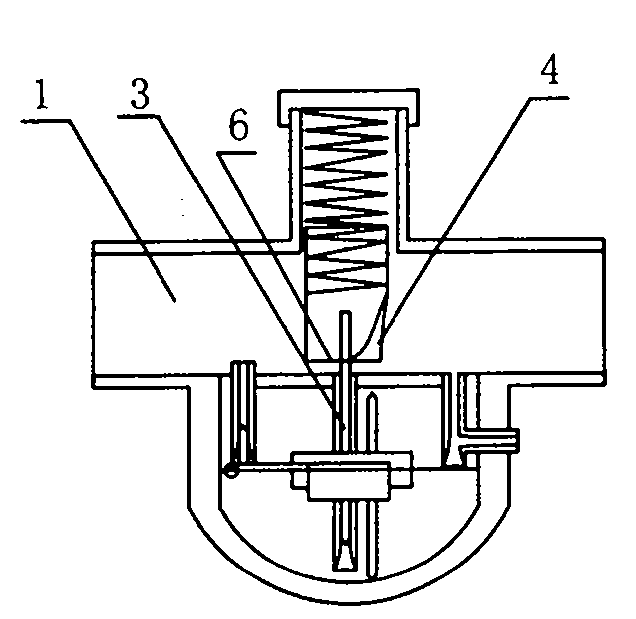

[0018] exist figure 1 and figure 2 or image 3 In the plunger type throttle valve vortex tail carburetor shown in the two embodiments shown, the vortex tail (4) is installed behind the plunger throttle (2) in the carburetor body assembly (1), and the vortex tail The bottom surface of (4) is flush with the bottom surface of the plunger throttle (2), and the initial width of the single-tail empennage both sides edges of the first embodiment is equal to the diameter of the plunger throttle (2) or the width of the air passage, and the root is equal to that of the plunger throttle (2). The rear wall of the plunger throttle (2) is attached, and the edges on both sides of the empennage start from the root as straight lines, elliptical lines or arcs intersect at the tail tip, and the cross-section of the empennage is an arc or an edge line with a straight line, the second The double-tailed (dovetail) empennage of embodiment then adds two edges and expands from the middle of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com