Structure for connecting heat insulation oil pipes

A technology for connecting structure and insulating oil pipes, which is applied in the direction of protecting pipes, pipes/pipe joints/fittings, and drilling pipes through heat insulation, which can solve the problems of leakage and inability to solve the connection structure of heat-insulating oil pipes, so as to reduce conduction and improve Insulation condition, effect of lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

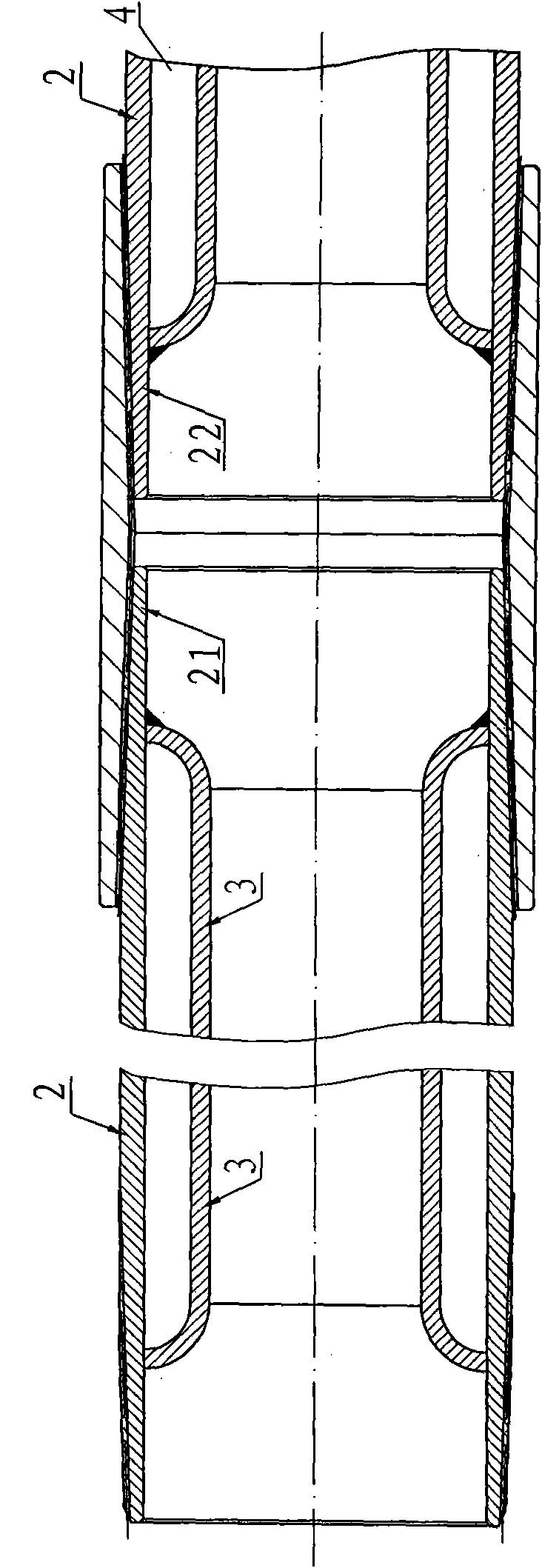

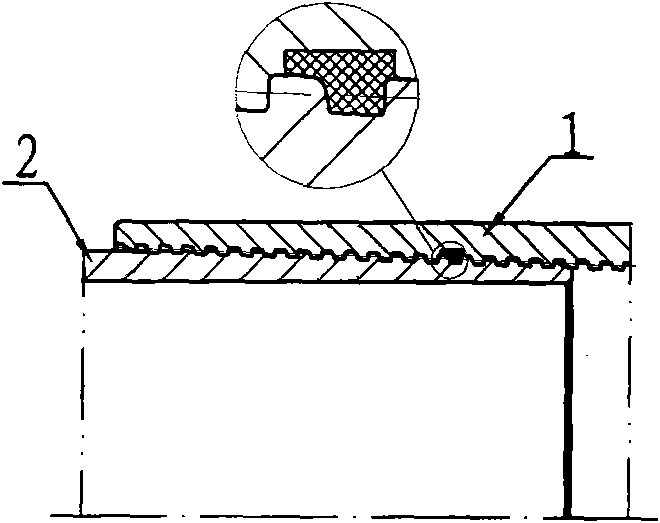

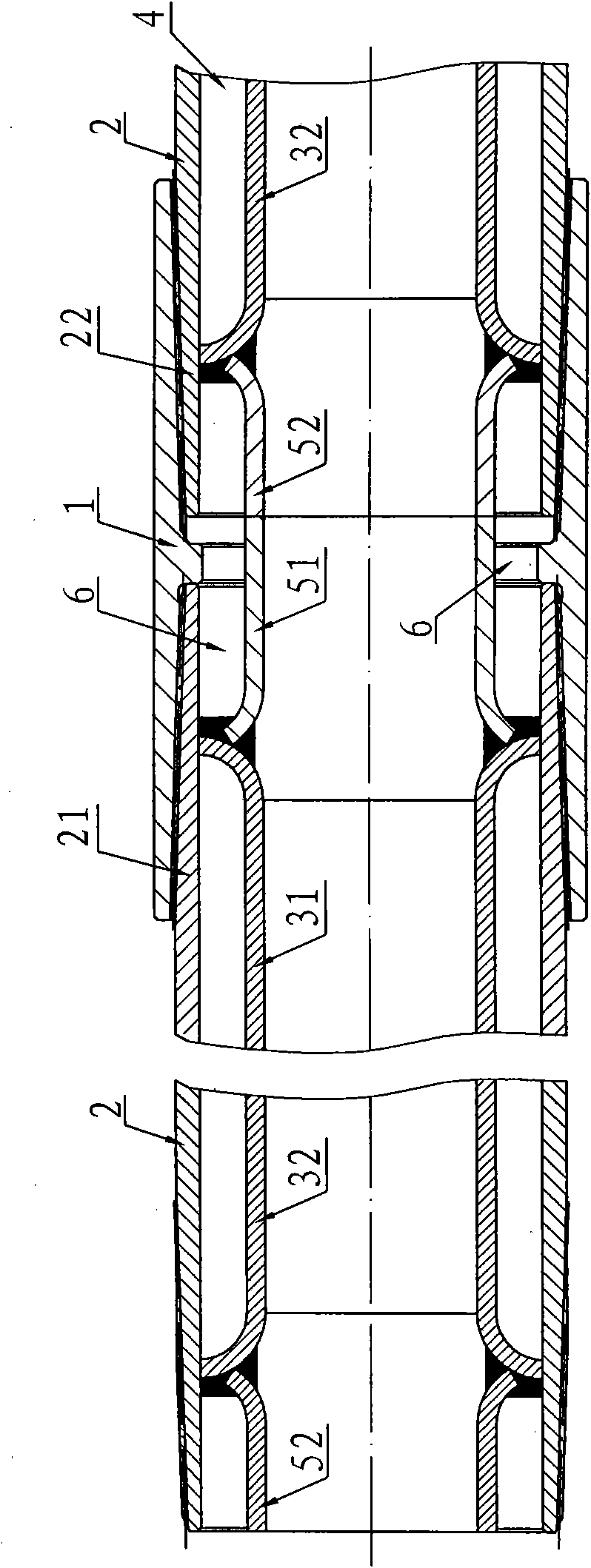

[0035] Embodiment 1: A connection structure of heat-insulated oil pipes, such as image 3As shown, it includes the coupling 1, the factory end 21 of the outer pipe threaded with the left end of the coupling 1, the user end 22 of the outer pipe threaded with the right end of the coupling 1, and the factory end 21 of the outer pipe is welded sealingly with the inner pipe factory end 31, in the user end outer tube 22, the inner tube user end 32 is welded sealingly, and the inner tube of the tube end is arranged between the inner tube factory end 31 and the inner tube user end 32 of the tube body, and the inner tube of the tube end is formed by the left The inner pipe 51 of the pipe end and the inner pipe 52 of the right pipe end are composed, the left end of the inner pipe 51 of the left pipe end is sealed and fixed together with the factory end 31 of the pipe body, and the right end of the inner pipe 52 of the right pipe end is sealed with the user end 32 of the pipe body Fixed ...

Embodiment 2

[0037] Embodiment 2: On the basis of Embodiment 1, a heat insulation sleeve 7 made of ceramic fibers is added in the closed pipe end heat insulation cavity 6, such as Figure 4 As shown, the outer circle and the inner hole wall of the heat insulation sleeve 7 are covered with aluminum foil 8, such as Figure 9 As shown, in this way, the heat insulation performance at the joint of the coupling 1 can be better, and the heat loss here can be further reduced.

Embodiment 3

[0038] Embodiment 3: On the basis of Embodiment 1, the sealing structure between the inner pipe 51 at the left pipe end and the inner pipe 52 at the right pipe end can be selected as follows Image 6 The shown axial end face interference butt seal structure; or select Figure 7 The combination of axial end surface interference butt seal and cylindrical surface radial interference fit seal; or select Figure 8 The combined structure of axial end surface interference butt joint seal and conical surface radial interference fit seal shown; the threaded end surface connecting the outer pipe factory end 21 and coupling 1 and the connecting thread end surface of the outer pipe user end 22 and coupling 1 are provided with The torque shoulder 9, and the included angle α between the end surface 91 of the outer pipe in the torque shoulder 9 and the limiting end surface 92 of the inner thread of the coupling and the positive direction of the thread axis is 90°. The role of setting the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com