Method for preparing high-purity magnesium oxide from nesquehonite by carbon-ammonia recycle method

A technology of magnesium carbonate trihydrate and magnesium oxide, applied in magnesium oxide and other directions, can solve the problems of large washing water consumption, high preparation temperature, poor filtration performance, etc., and achieve the effects of saving energy consumption, simple method and reducing water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

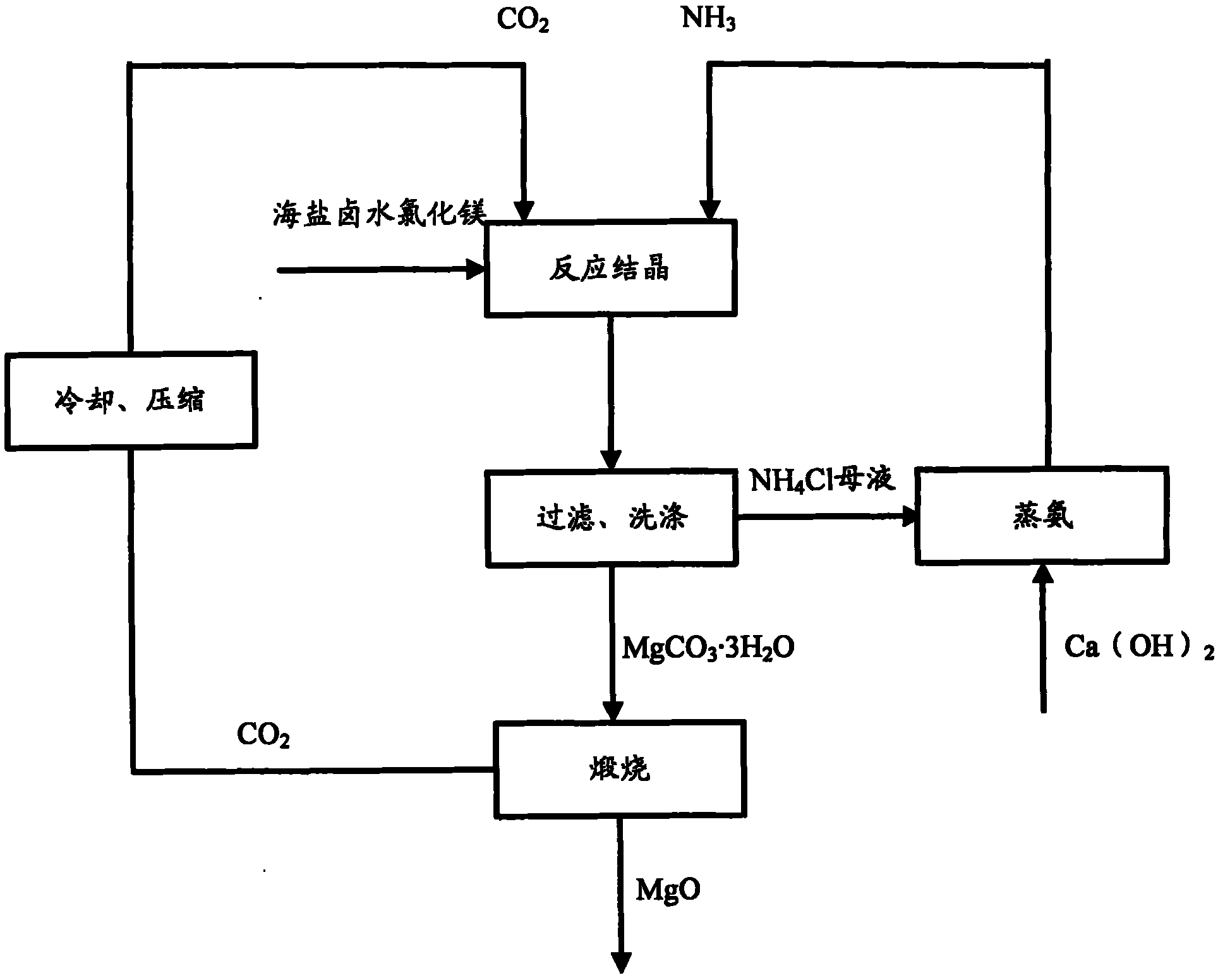

[0030] For the specific process flow of this embodiment, please refer to figure 1 .

[0031] (1) prepare magnesium carbonate trihydrate intermediate

[0032] The brine magnesium chloride is configured as a magnesium chloride solution with a concentration of 0.5 mol / L, and added to the reaction crystallization kettle, the temperature is controlled at 20°C, and ammonia and carbon dioxide are fed into the reaction crystallization kettle under stirring conditions. The equivalent ratio of magnesium and ammonia is 1:2, the flow rate of ammonia is 0.5 liter / min, and the flow rate of carbon dioxide is 0.25 liter / min. Stop feeding when the concentration of magnesium chloride in the solution reaches 0.01mol / L, and continue to stir for 30 minutes. The filtered solid is an intermediate of magnesium carbonate trihydrate. The filtrate obtained after filtration is then used as raw material for ammonia distillation.

[0033] (2) Filtration and washing of magnesium carbonate trihydrate

...

Embodiment 2

[0040] For the specific process flow of this embodiment, please refer to figure 1 .

[0041] (1) prepare magnesium carbonate trihydrate intermediate

[0042] The brine magnesium chloride is configured into a magnesium chloride solution with a concentration of 4.5 mol / L, and added to the reaction crystallization kettle, the temperature is controlled at 40°C, and ammonia and carbon dioxide are introduced into the reaction crystallization kettle under stirring conditions. The equivalent ratio of magnesium and ammonia is 1:2, the flow rate of ammonia is 1.5 liters / minute, and the flow rate of carbon dioxide is 1.0 liters / minute. Stop feeding when the concentration of magnesium chloride in the solution reaches 0.05mol / L, and continue to stir for 120 minutes. The filtered solid is an intermediate of magnesium carbonate trihydrate. The filtrate obtained after filtration is then used as raw material for ammonia distillation.

[0043] (2) Filtration and washing of magnesium carbona...

Embodiment 3

[0050] For the specific process flow of this embodiment, please refer to figure 1 .

[0051] (1) prepare magnesium carbonate trihydrate intermediate

[0052] The brine magnesium chloride is configured as a magnesium chloride solution with a concentration of 3 mol / L, and added to the reaction crystallization kettle, the temperature is controlled at 30°C, and ammonia and carbon dioxide are introduced into the reaction crystallization kettle under stirring conditions. The equivalent ratio of magnesium and ammonia is 1:2, the flow rate of ammonia is 1.0 liter / min, and the flow rate of carbon dioxide is 0.75 liter / min. Stop feeding when the concentration of magnesium chloride in the solution reaches 0mol / L, and continue to stir for 90 minutes. The filtered solid is an intermediate of magnesium carbonate trihydrate. The filtrate obtained after filtration is then used as raw material for ammonia distillation.

[0053] (2) Filtration and washing of magnesium carbonate trihydrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com