Horizontal furnace tube and method for producing in-situ doped polysilicon

A horizontal furnace and polysilicon technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of poor uniformity of polysilicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

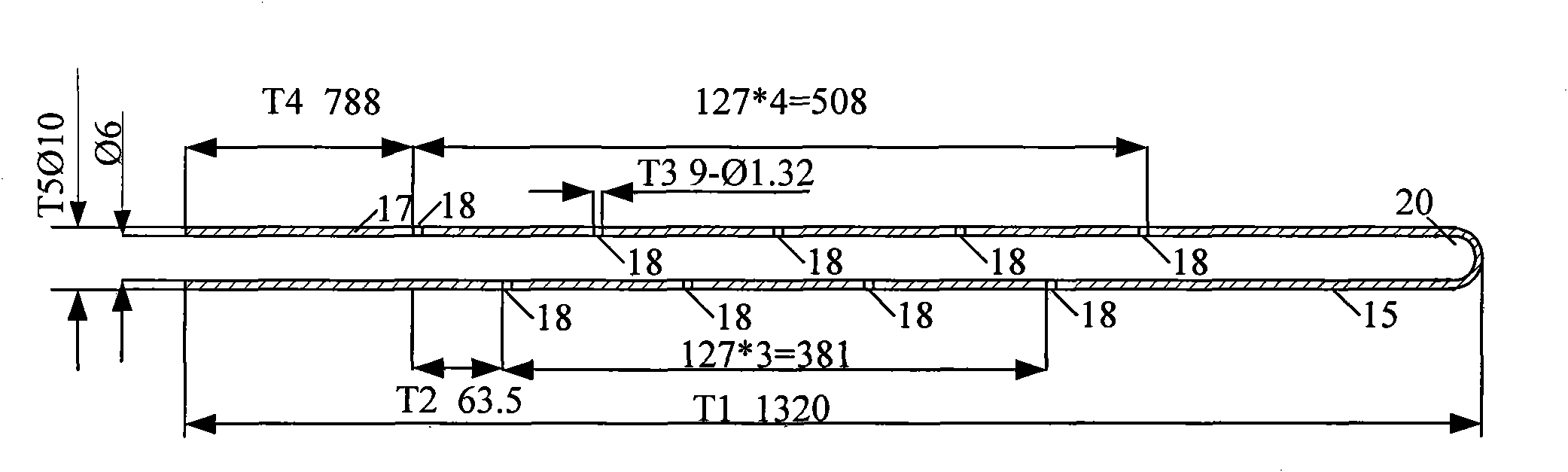

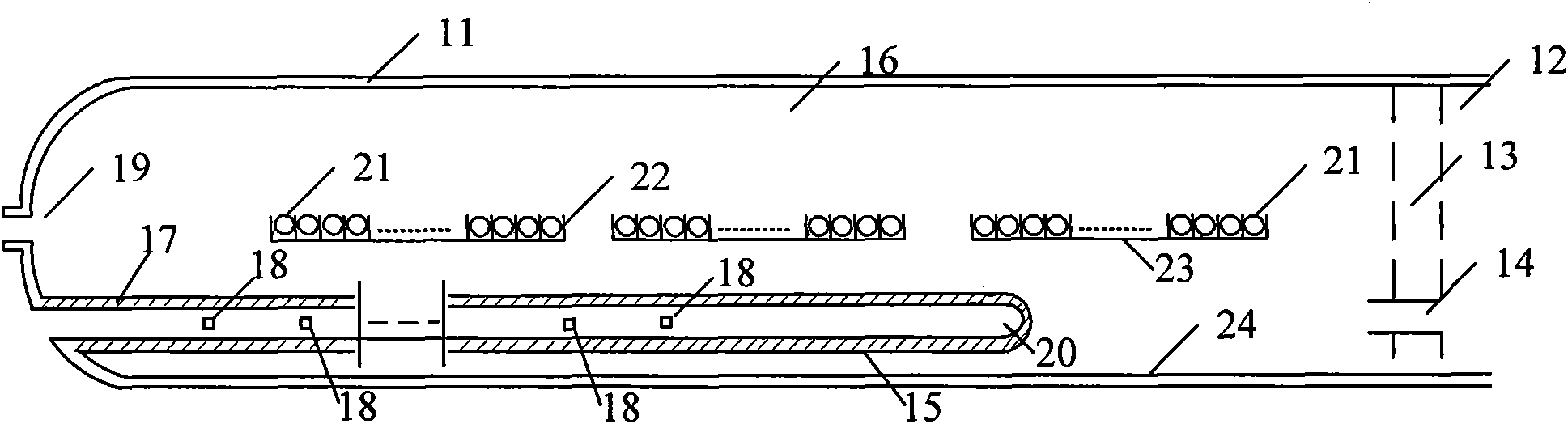

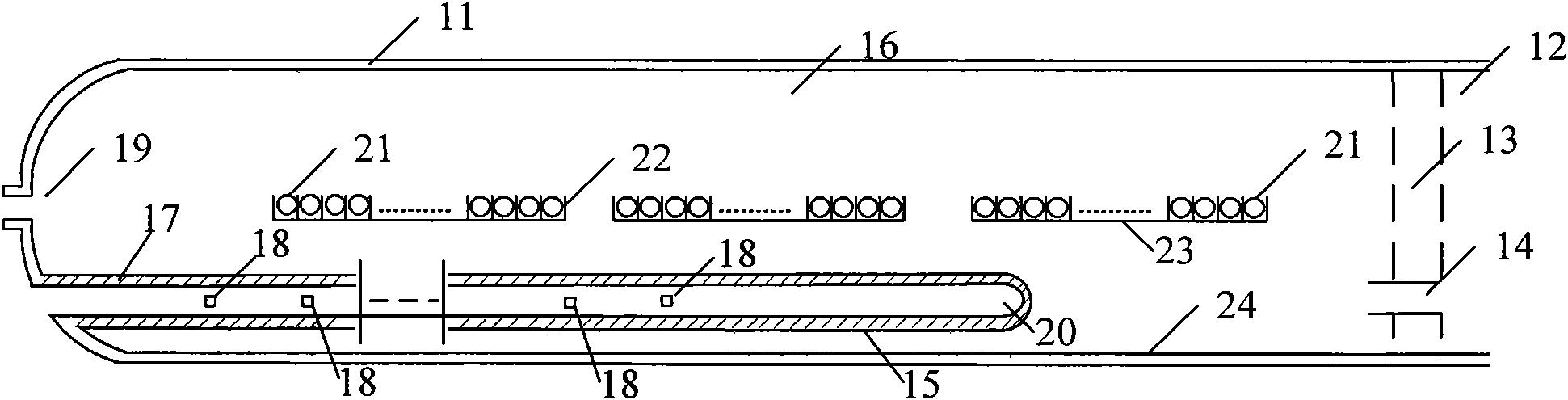

[0014] In order to solve the following problems in the prior art: when synthesizing in-situ doped polysilicon, the uniformity of the polysilicon is poor. The embodiment of the present invention provides a horizontal furnace tube for producing in-situ doped polysilicon, a tube body 11 and a reaction chamber 16 surrounded by the tube body 11, a tubular gas injector 15 at the furnace end 12 of the tube body 11 Extending into the reaction chamber 16 along the axial direction of the tube body 11, a plurality of small holes 18 are opened on the tube wall 17 of the injector 15, and the end 20 away from the gas injection is closed. Since the reaction gas is injected through the injector 15, the phosphine and silane are evenly distributed in the furnace tube cavity, which improves the thickness uniformity of the in-situ doped polysilicon, and controls the uniformity within 3%. React on 3 boats to form qualified in-situ doped polysilicon, now it can react on 8 boats to form qualified in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com