Supergravity membrane separator consisting of a plurality of independent membrane assemblies fixed on rotating disk

A membrane module and membrane separation technology, applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problems of large structure, concentration polarization, membrane pollution, and high cost, and achieve flux per unit membrane area Large, high retentate concentration, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

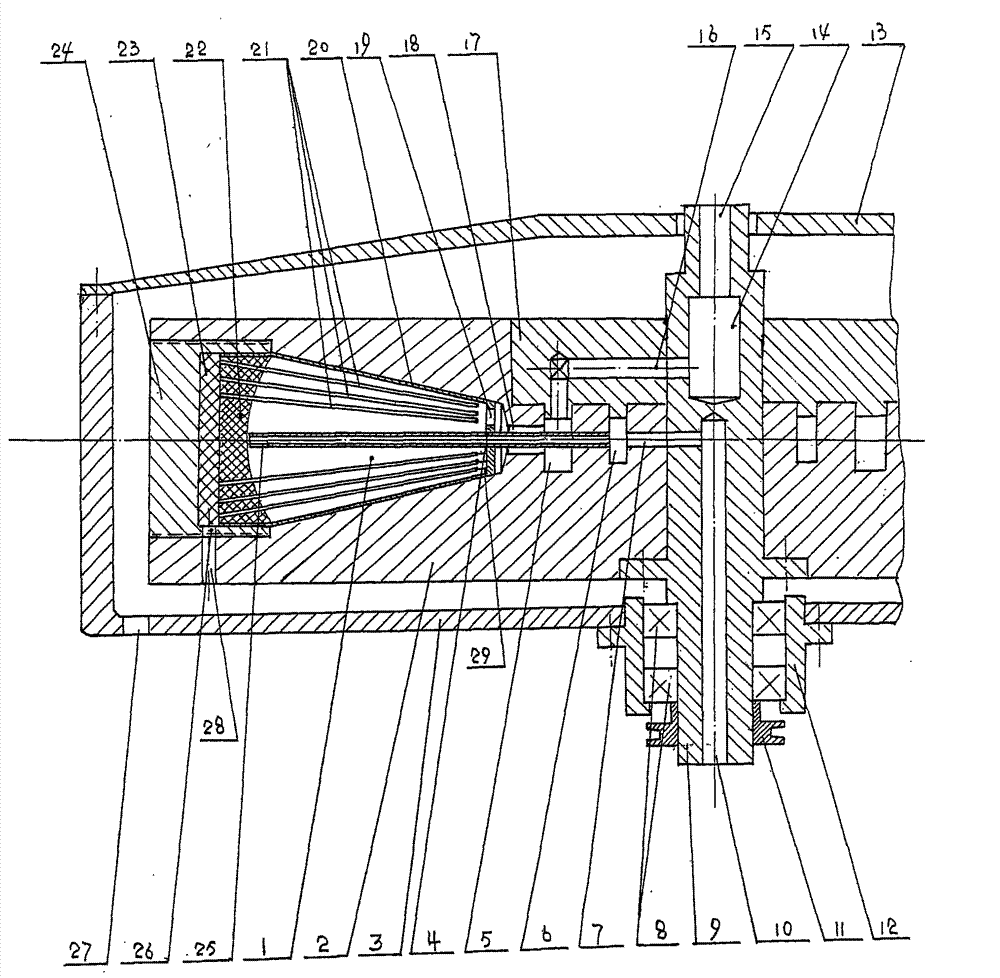

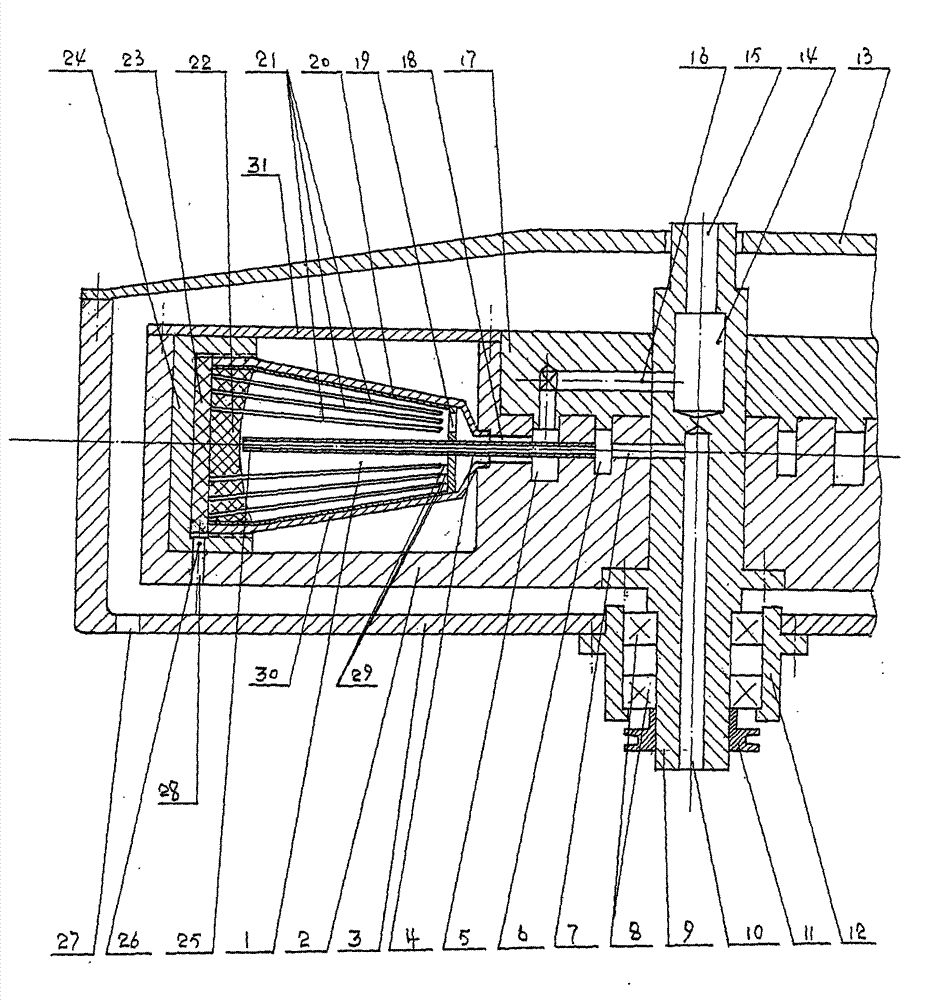

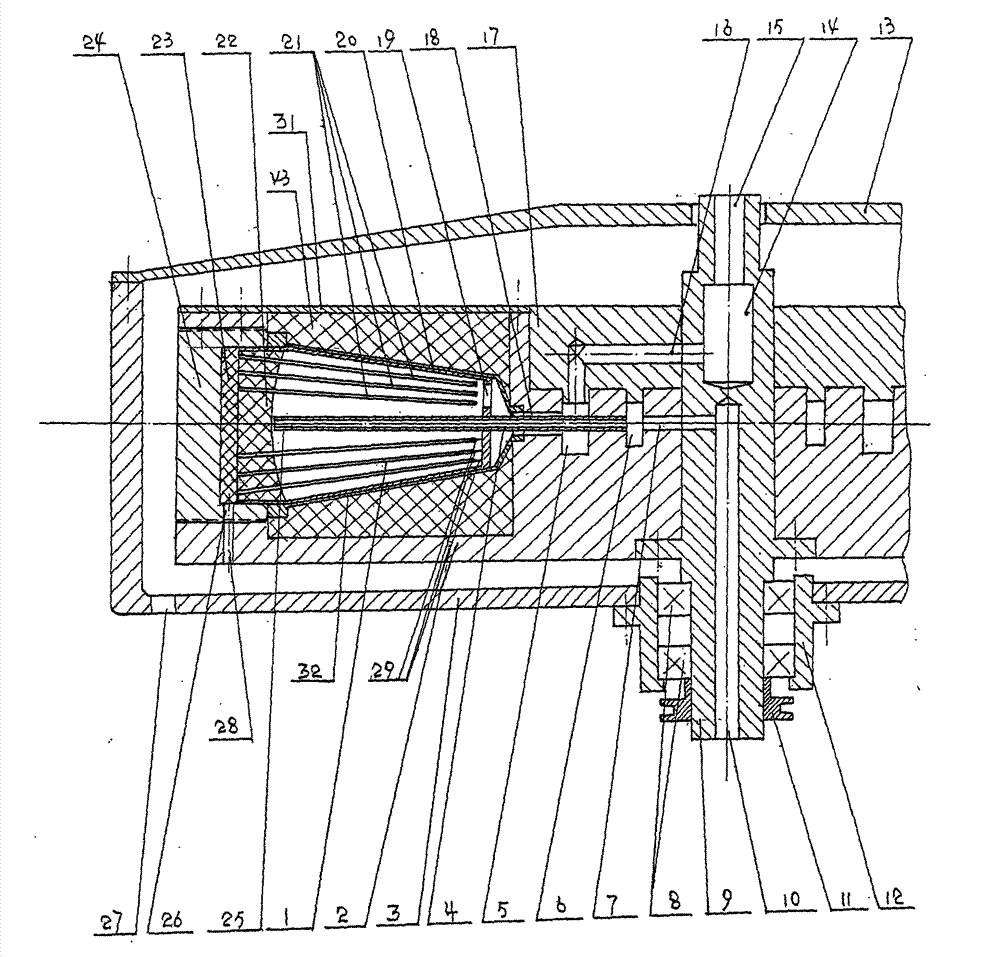

[0031] first with figure 1 Describe the structure, working principle and implementation method of the membrane separator working under the condition of supergravity with the membrane module (1) installed in the tapered hole processed and formed in the turntable (2).

[0032] figure 1 The described high-gravity membrane separator consists of a membrane module (1), a turntable (2), a frame (3), a central catheter (4), a bearing (8), a main shaft (9), and a main shaft transmission part (11) , support sleeve (12), loam cake (13), gland (17), porous support plate (23) and cock (24) form. Wherein the membrane assembly (1) is composed of a separation membrane (21), a membrane casing (20), a membrane fixing epoxy resin (22) and a fine wire (29). The separation membrane may be a hollow fiber membrane, a capillary membrane or a tubular membrane. The separation membrane (21) is arranged in the membrane casing (20) in an umbrella-shaped or conical spiral shape, and its end away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com