Magnetic valve

A technology of solenoid valve and valve seat, applied in the field of solenoid valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

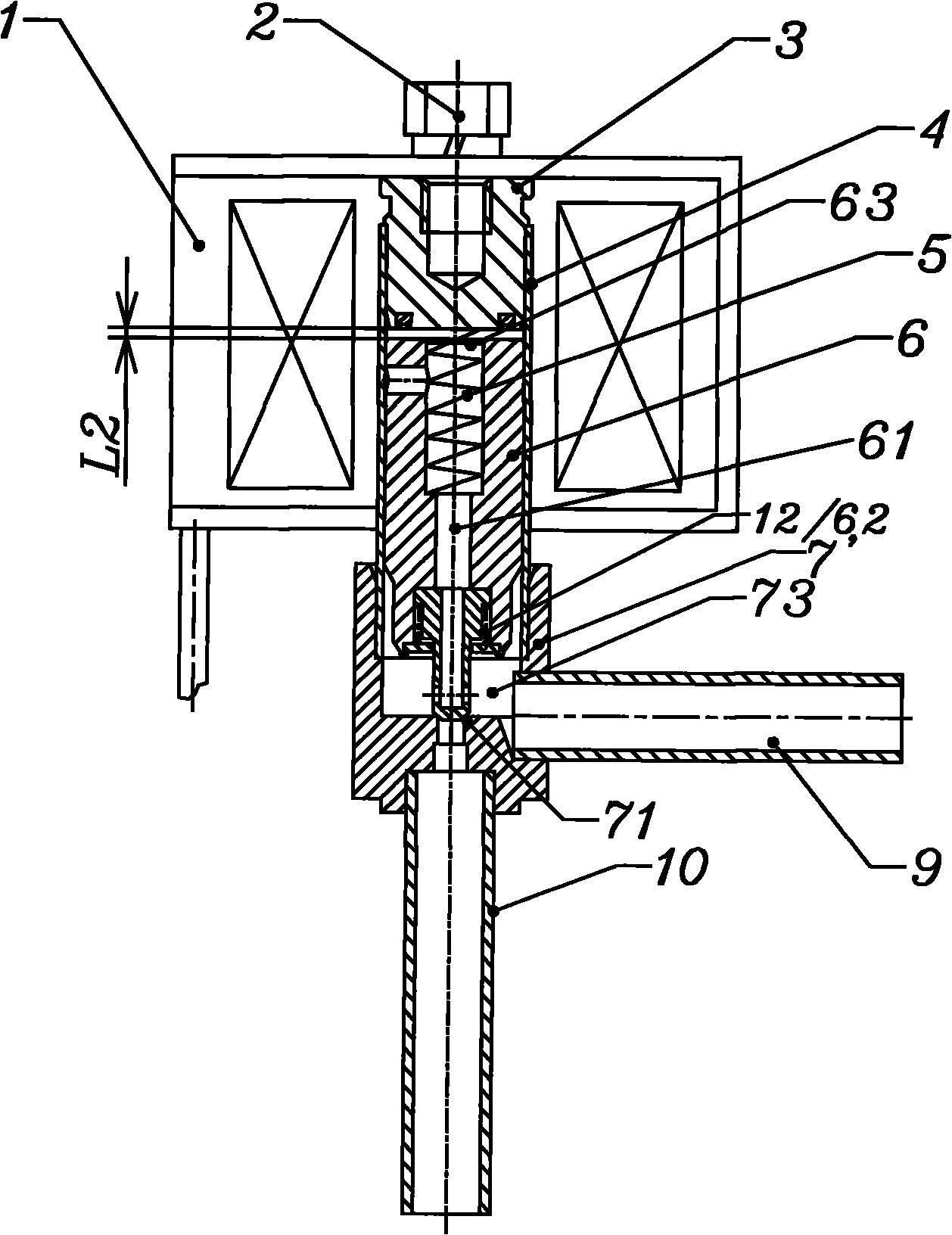

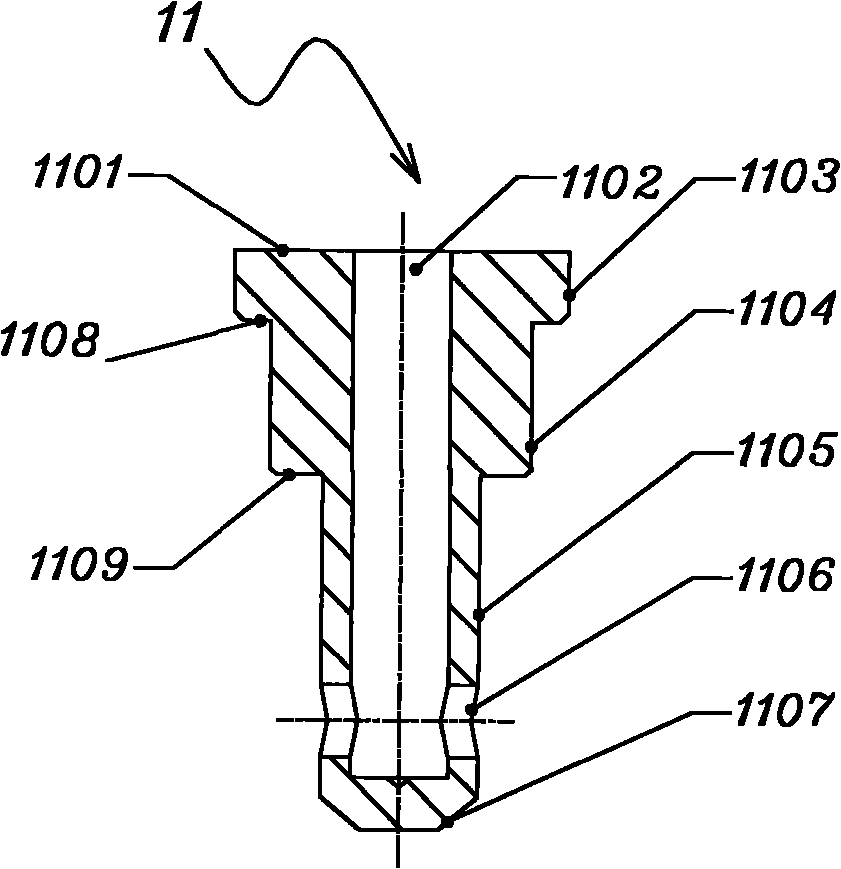

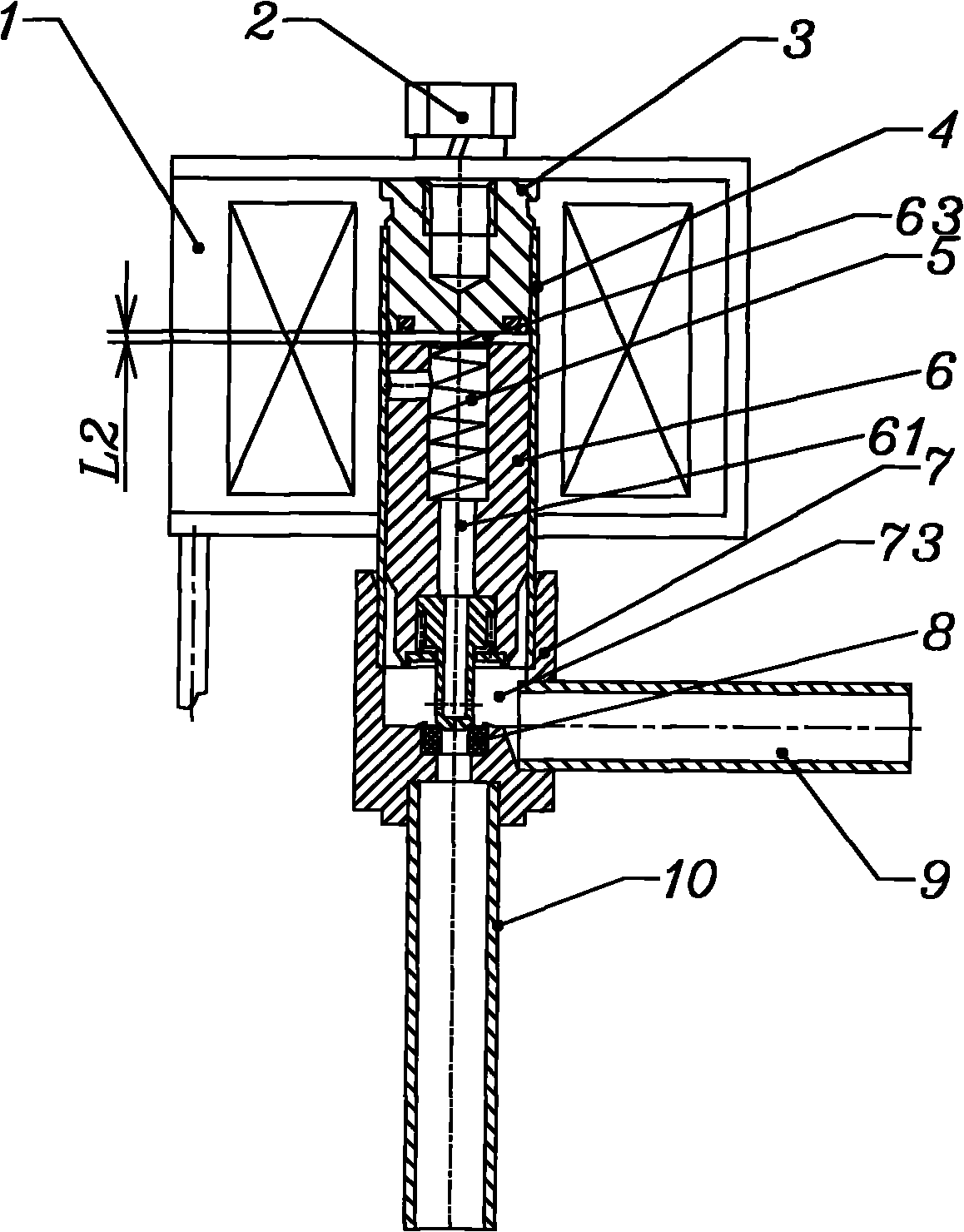

[0042] Introduce the second embodiment of the present invention below, image 3 It is a structural schematic diagram of the second embodiment of the solenoid valve of the present invention, Figure 4 for image 3 The schematic diagram of the partially enlarged structure of the valve port between the seal and the valve seat when the solenoid valve shown is closed, Figure 5 for image 3 The partial enlarged structural diagram of the seal and the valve port of the solenoid valve shown at the moment of opening, Image 6 for image 3 The partial enlarged structure diagram of the seal and the valve port after the solenoid valve is opened is shown.

[0043] As shown in the figure, the main difference between this embodiment and the above-mentioned first embodiment is that the valve seat in this embodiment is formed by a combined structure: the valve seat includes a valve seat portion 7 and a valve port portion 8, which are formed by combination, The valve port 8 is made of engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com