Novel efficient insulating mould coating

A heat-insulating coating, high-efficiency technology, applied in the direction of coating, etc., can solve the problems of inconvenient construction, less heat-insulating cavity, low volume solid content of coating, etc., to reduce production and transportation costs, reduce thermal conductivity, high volume solid The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

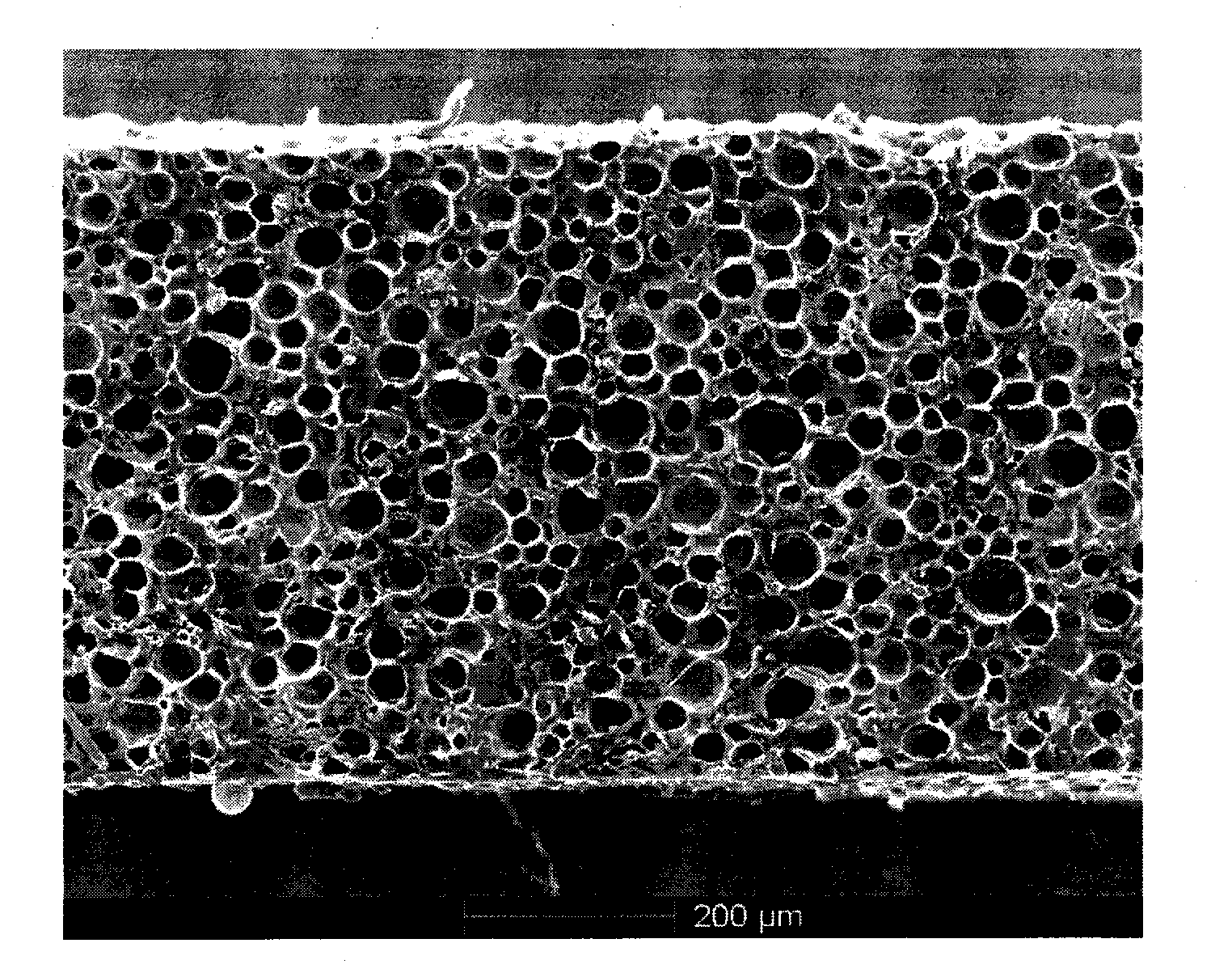

Image

Examples

Embodiment 1

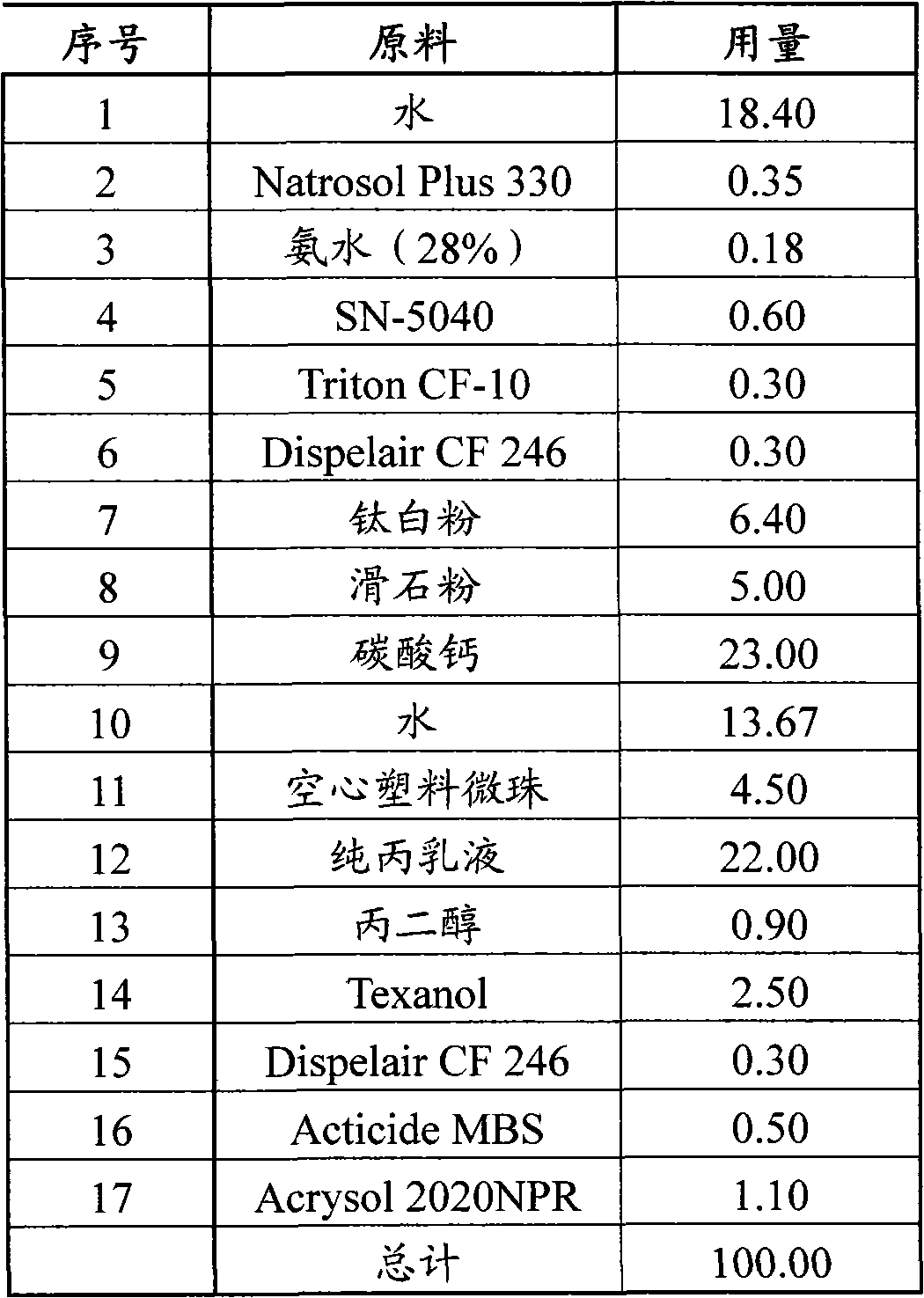

[0028]

[0029] This example is a dark base paint for a new type of high-efficiency heat-insulating coating. The preparation includes the following steps: First, slowly add raw materials 1 to 3, and disperse at a low speed for 5 minutes; slowly add raw materials 4 to 6, and disperse at a low speed for 5 minutes; add raw materials 7 Add ~9 slowly, high speed for 30 minutes; slowly add raw materials 10~11, and disperse at medium speed for 20 minutes; slowly add raw materials 12~17, and disperse at low speed for 30~45 minutes. After stirring evenly like this, promptly make the novel high-efficiency heat-insulating paint of the present invention.

Embodiment 2

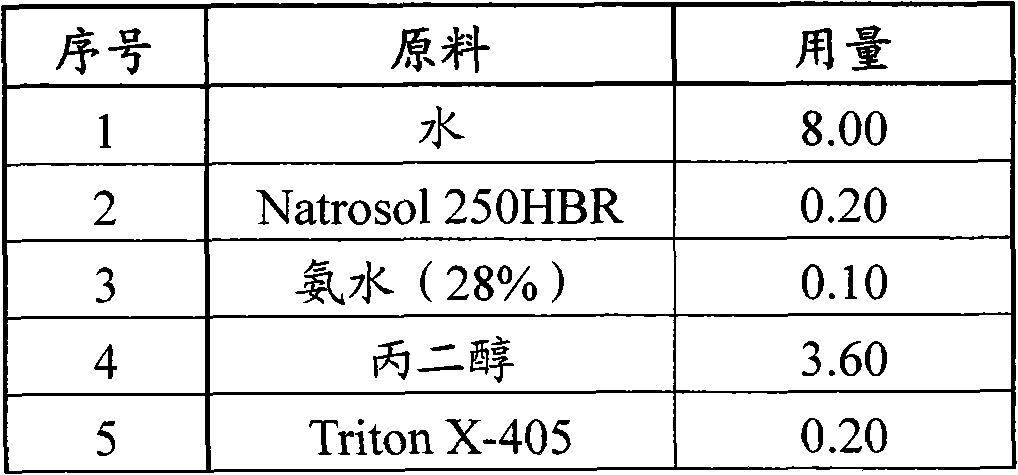

[0031] serial number

[0032] 7

[0033] This example is a matching primer for a novel high-efficiency heat-insulating coating, and its preparation steps refer to Example 1.

Embodiment 3

[0035]

[0036]

[0037] This example is a new type of high-efficiency heat-insulating elastic coating, and its preparation includes the following steps: First, slowly add raw materials 1 to 3, and disperse at a low speed for 5 minutes; slowly add raw materials 4 to 7, and disperse at a low speed for 5 minutes; add raw materials 8 to 9 slowly Add in high speed for 30 minutes; slowly add raw materials 10-11 and disperse at medium speed for 20 minutes; slowly add raw materials 12-15 and disperse at low speed for 30-45 minutes. After stirring evenly, the novel high-efficiency heat-insulating elastic coating of the present invention is obtained.

[0038] The thermal insulation coating in Example 1 is compared with the hollow glass microsphere thermal insulation coating in the market according to JG / T 235-2008 (building industry standard for architectural reflective thermal insulation coatings). It can be seen that the coating prepared by hollow plastic microspheres has good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com