High-speed copper line wire drawing machine uncoiling device

A technology of pay-off device and wire drawing machine, which is used in transportation and packaging, transportation of filamentous materials, thin material processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

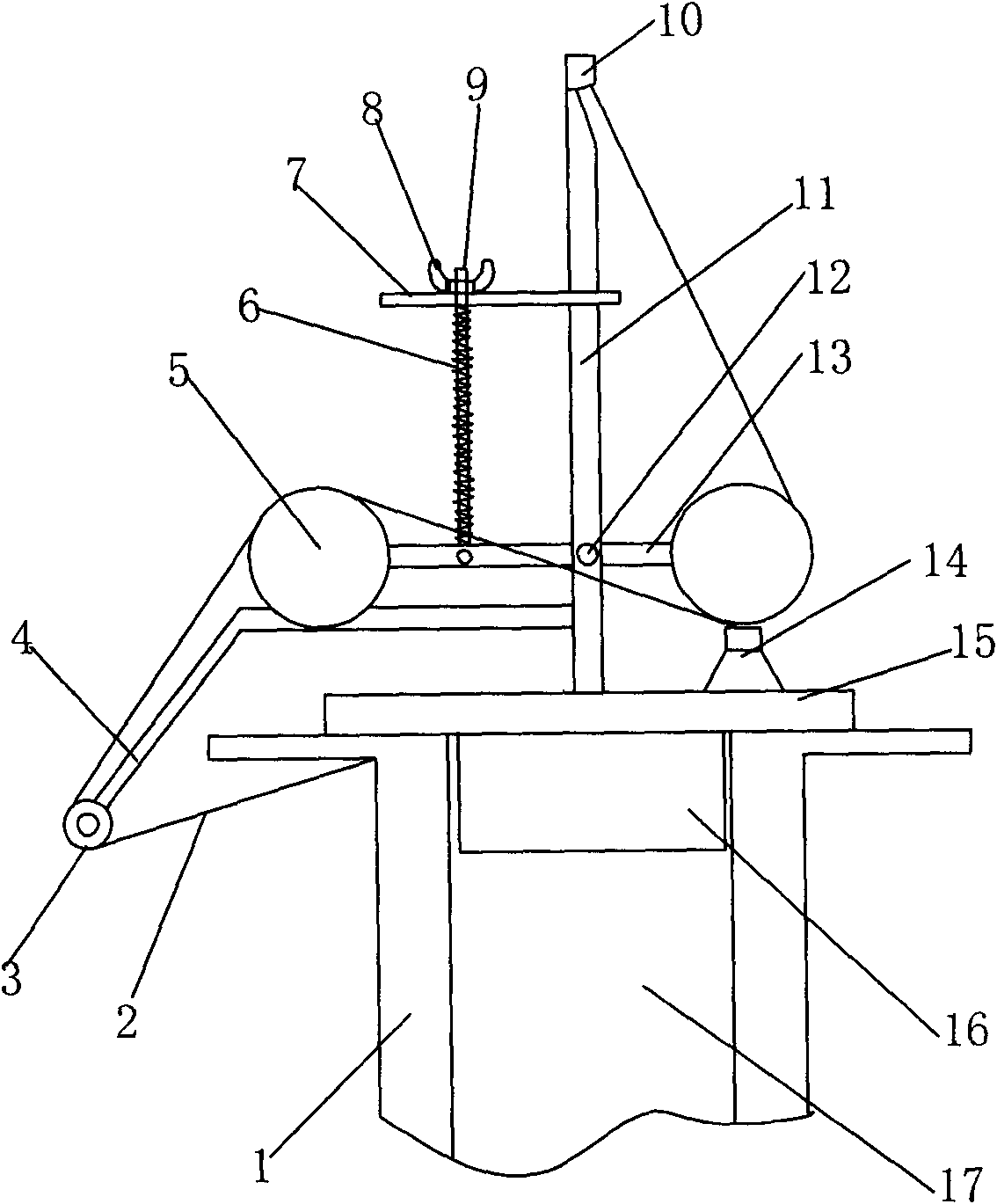

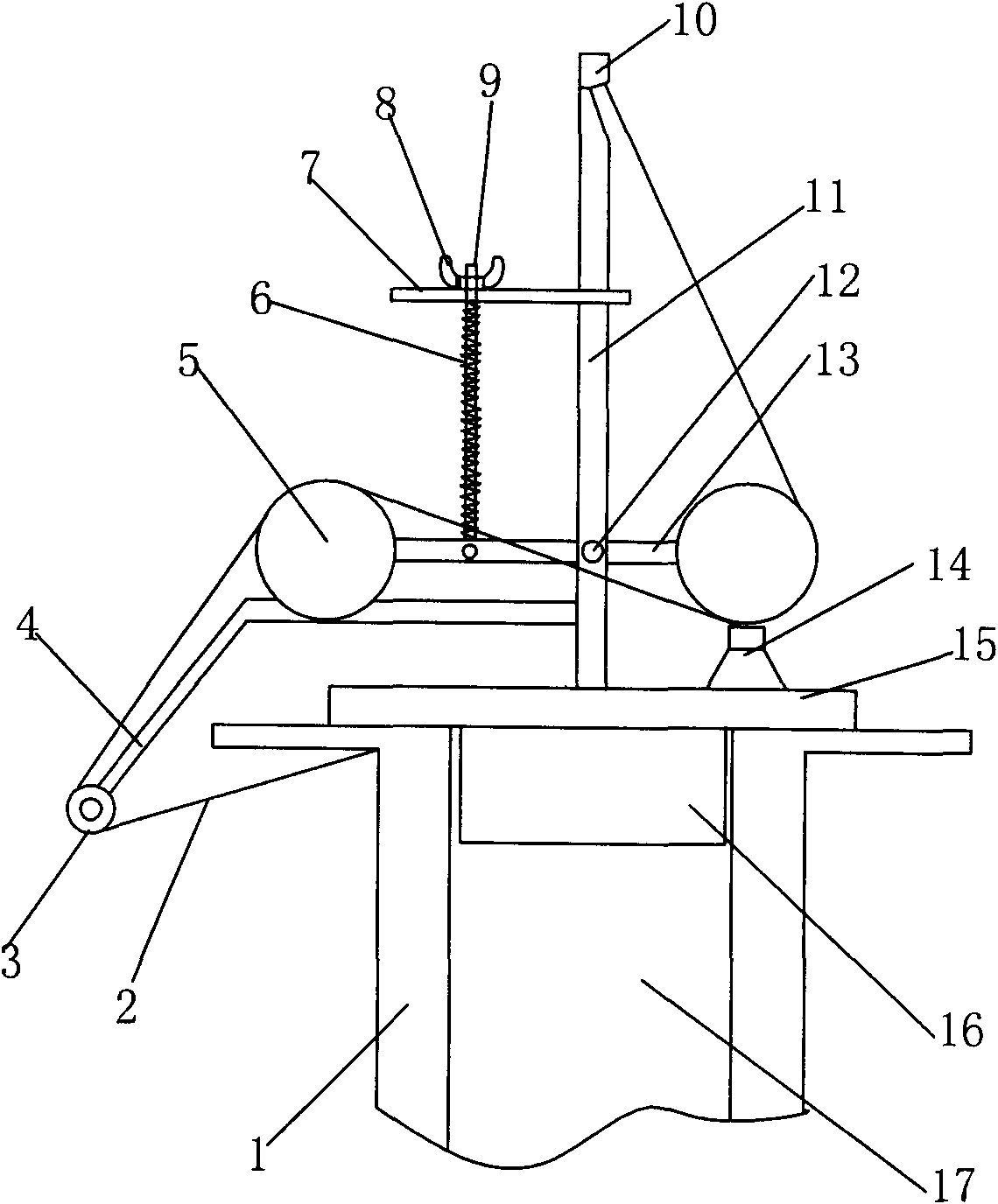

[0009] The high-speed copper wire drawing machine pay-off device of the present invention, such as figure 1 As shown, it includes a base 15, a rotating shaft 11 vertically connected to the base 15 through bearing rotation, a lever 13 and a lead rod 4, and the base 15 is provided with a round platform 16 matching the center hole 17 of the reel 1 below the base 15. The upper end of the rotating shaft 11 is fixed with a ceramic sleeve 10 that is convenient for the copper wire 2 to slide away. The lever 13 is connected to the rotating shaft 11 by the lateral rotation of the pin shaft 12. The two ends of the lever 13 are respectively rotated and connected with two guide wheels 5. 11 is fixedly connected, and the other end is rotatably connected with a guide sleeve 3, and a horizontal shaft 7 is fixedly connected horizontally on the rotating shaft 11. A screw rod 9 is arranged between the horizontal shaft 7 and the lever 13, and the lower end of the screw rod 9 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com