Hydraulic pulse-assisted reservoir chemical remedial treatment experiment device and method

A technology of hydraulic pulse and experimental equipment, which is applied in measuring equipment, scientific instruments, earthwork drilling and mining, etc., and can solve problems such as poor plugging effect, short action time, and small distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

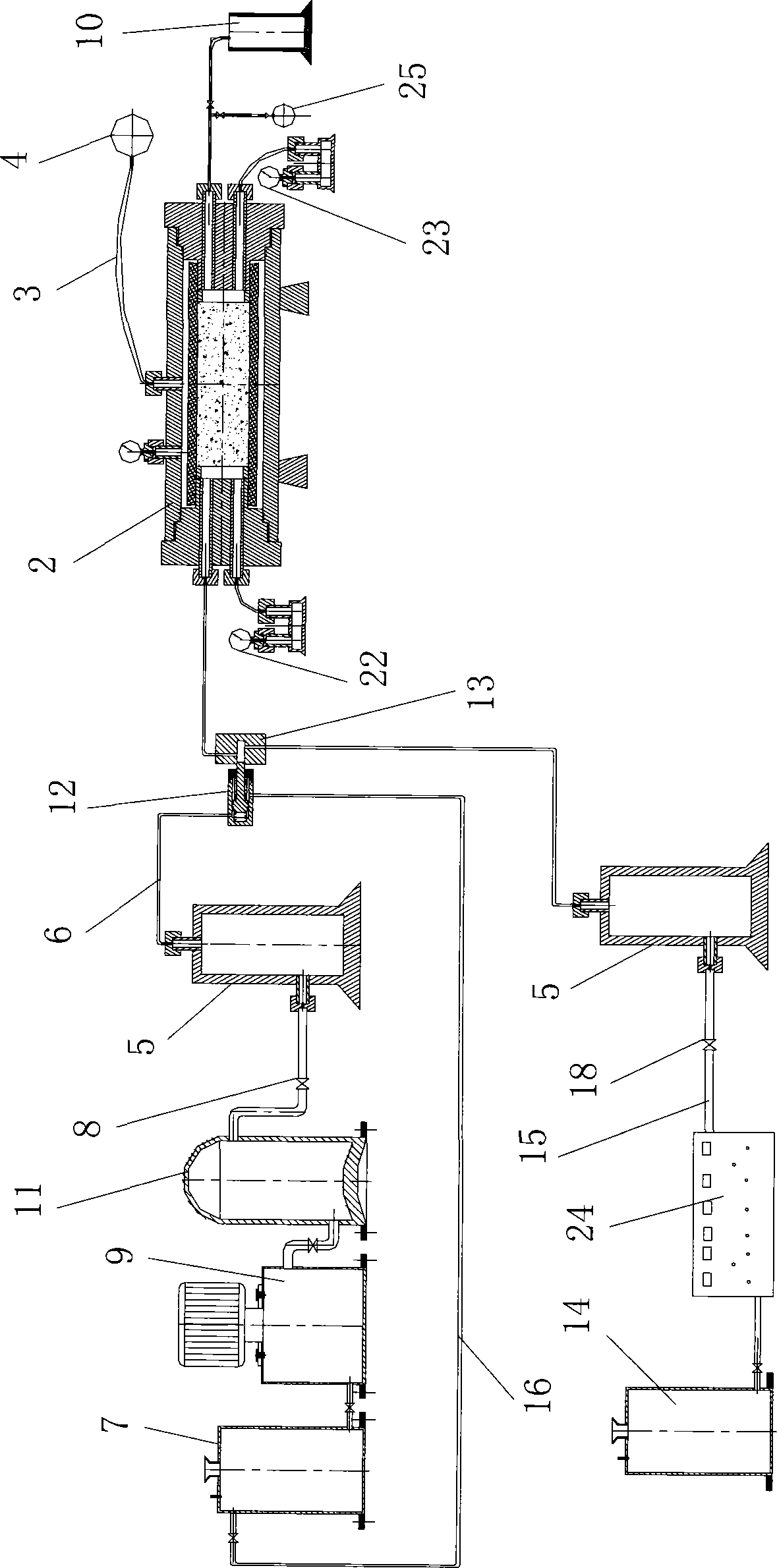

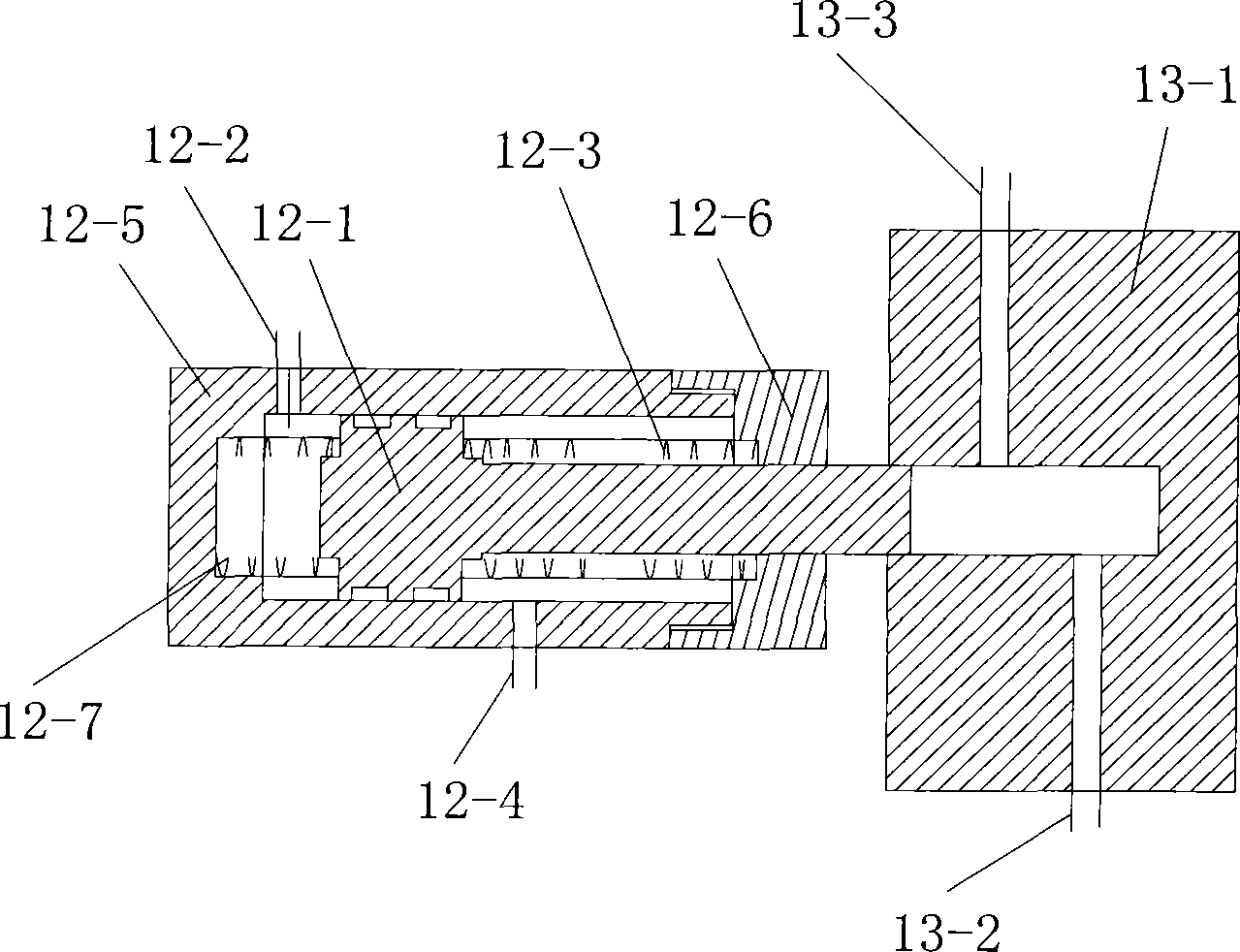

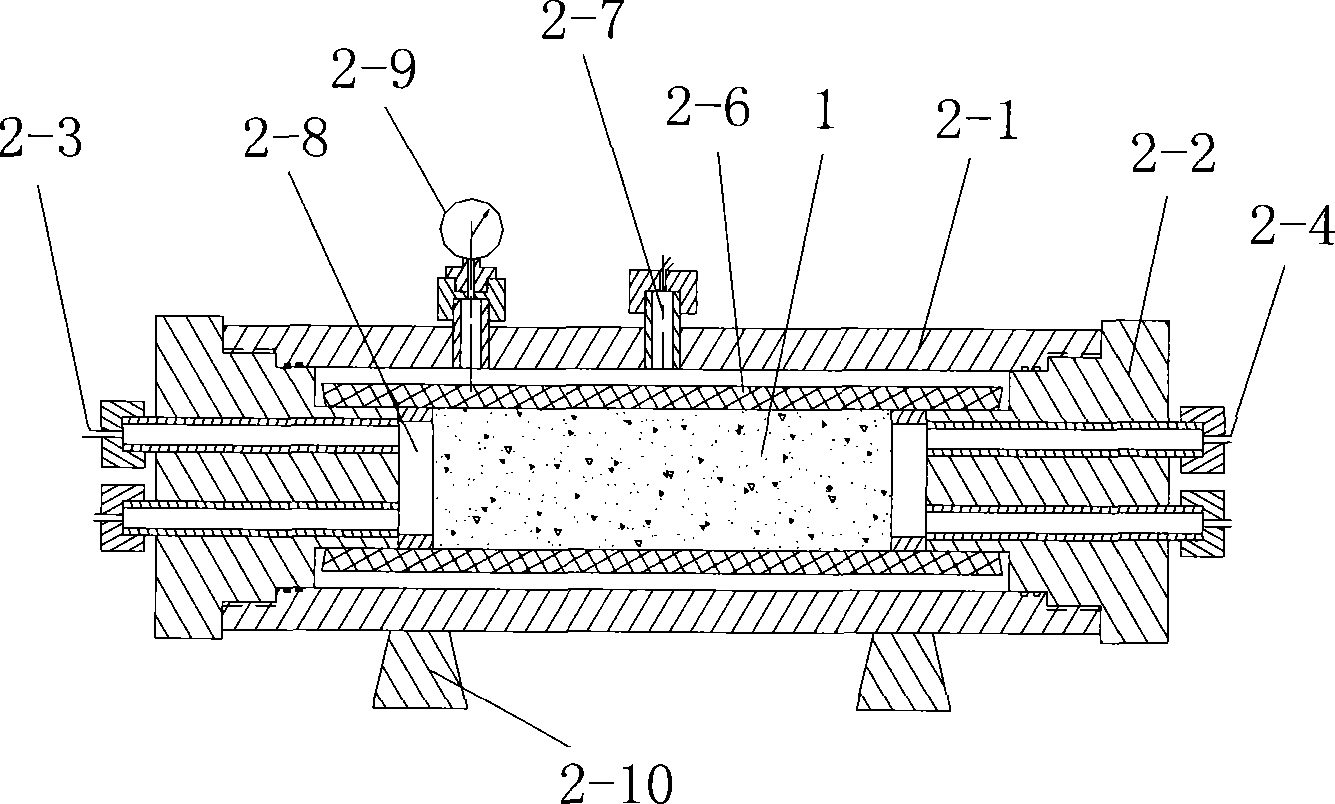

[0069] Such as figure 1 , Figure 4 The shown hydraulic pulse assisted reservoir chemical plugging removal experiment device includes a core holder 2 for holding the tested core 1, a constant temperature box arranged outside the core holder 2, and a hydraulic pipeline 3 Connected with the ring pressure interface of the core holder 2 and apply the ring pressure supply device 4 that applies ring pressure to the tested rock core 1 clamped inside the core holder 2, through the chemical reagent delivery pipeline and the core The chemical reagent storage tank connected to the liquid inlet of the holder 2 is connected to the liquid inlet of the core holder 2 through water pipelines and oil pipelines respectively, and simulated formation water and simulated formation oil are respectively installed inside. A water storage tank, an oil storage tank, and a liquid container connected to the liquid outlet of the core holder 2 through an external pipeline, the liquid container is marked wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com