Reflective LED grille lamp

An LED grille light and reflective technology, applied in the field of grille lights, can solve the problems of high light source cost and large light loss, and achieve the effect of high light output efficiency, small light loss, and improved light output efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

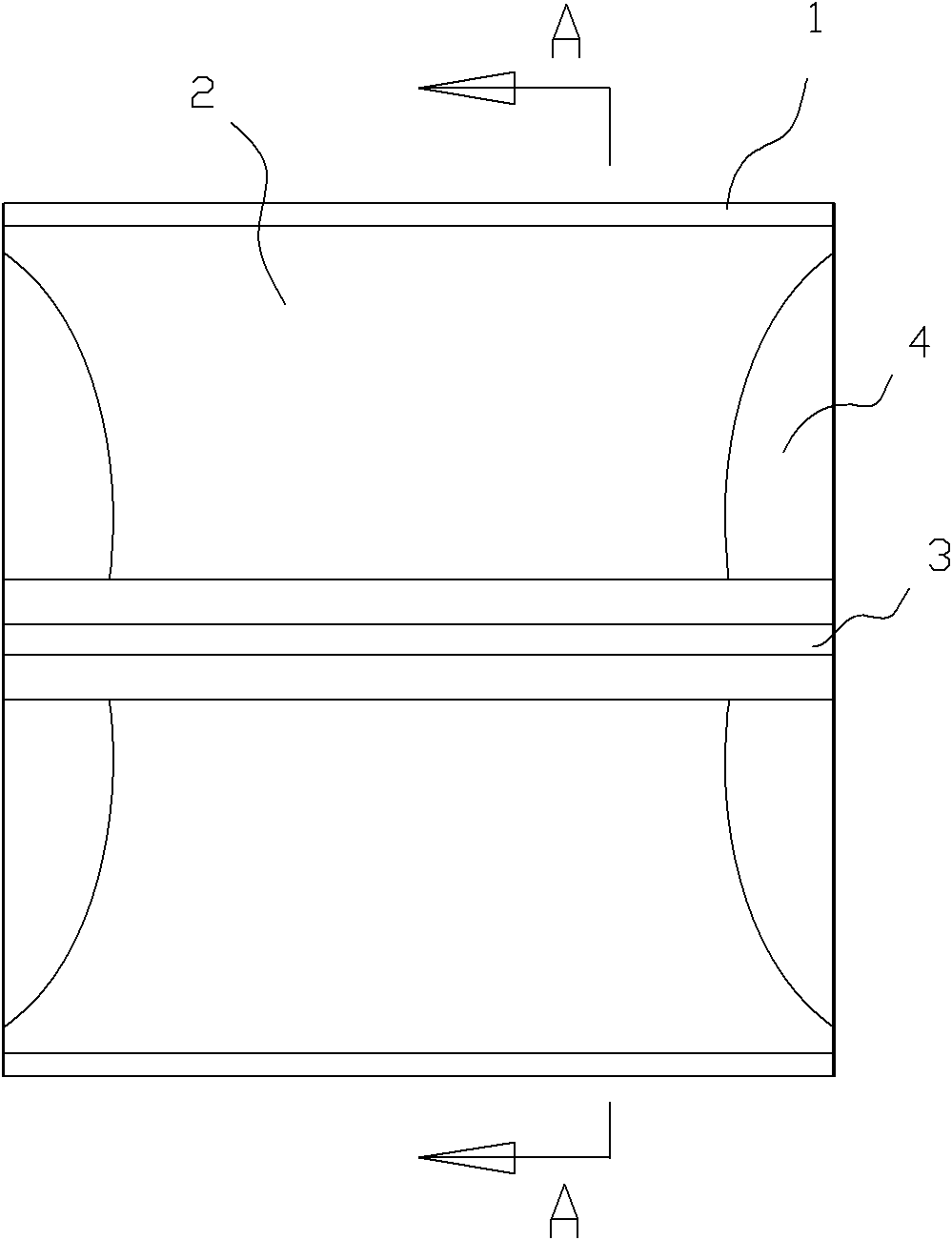

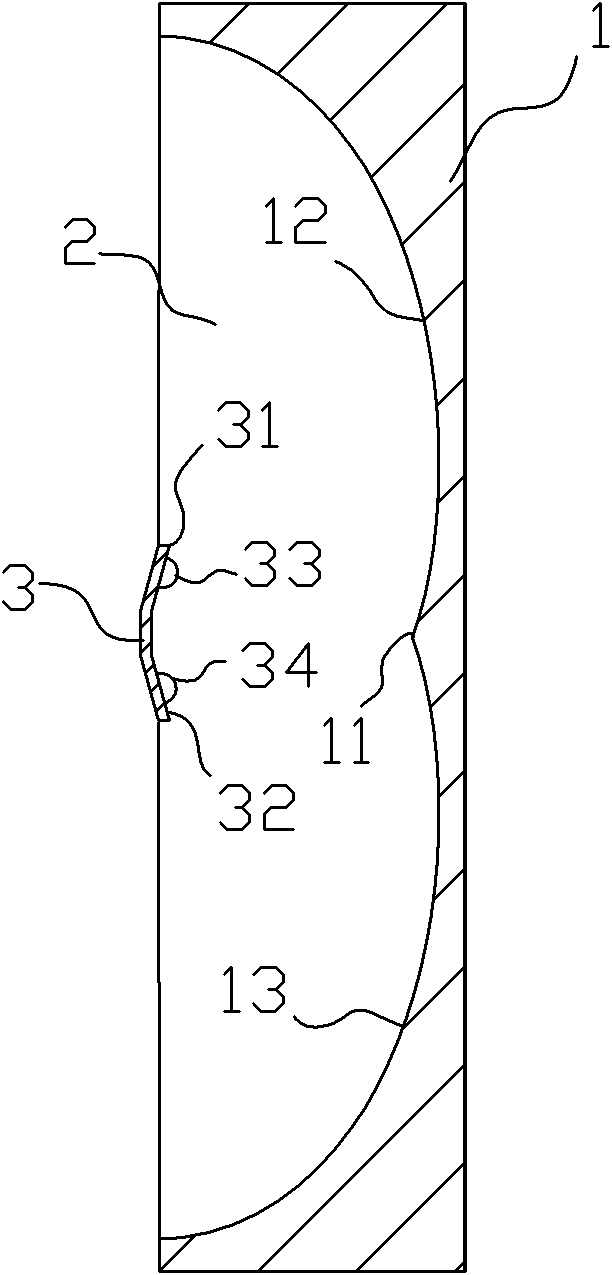

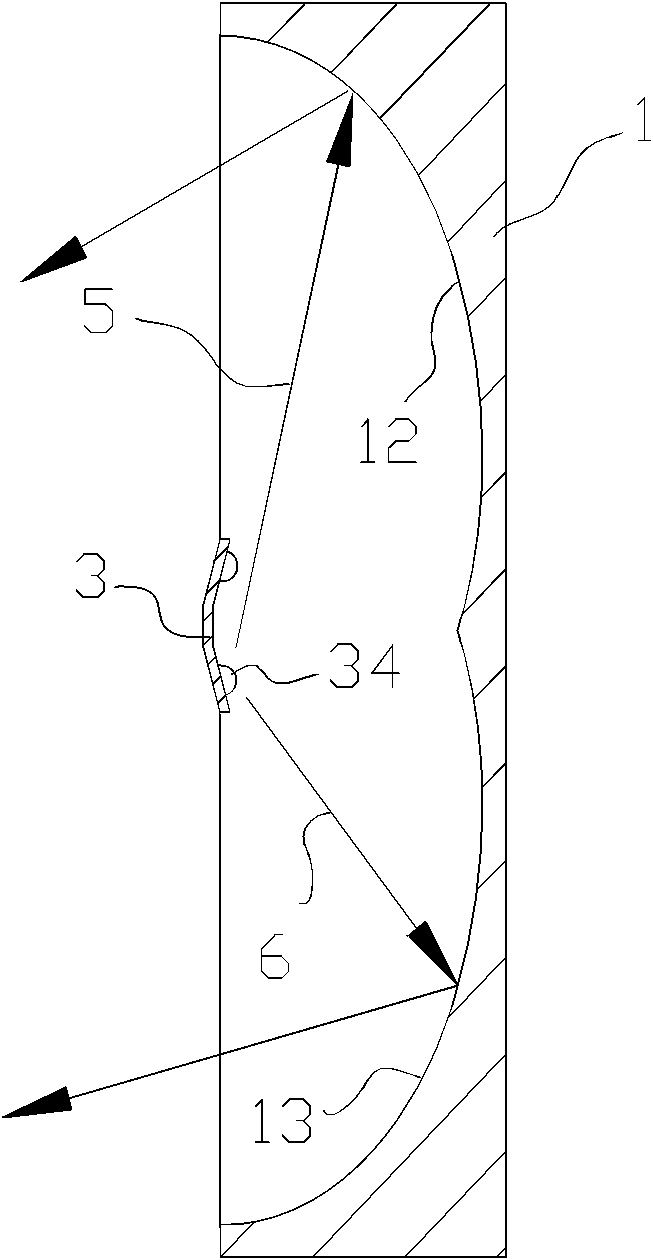

[0015] like figure 1 , figure 2 As shown, the present invention includes a lamp housing 1, LED light sources 33 and 34 and their driving power sources (not shown in the figure), the lamp housing 1 is a square structure, and the inner side of the lamp housing 1 is provided with an inwardly concave shape formed by a free reflective curved surface. Reflective cavity 2, the surface of the reflective cavity 2 is a free reflective curved surface, and the reflective curved surface is coated with a high-reflectivity material, which can increase the light-emitting efficiency of the lamp to more than 0.85. A beam 3 is fixed in the middle of the outlet end of the reflector cavity 2 of the lamp housing. The part corresponding to the center line of the reflector cavity 2 of the lamp housing and the beam 3 has a raised dividing line 11. The vertical distance from the dividing line 11 to the inner side of the beam 3 is 100mm~ 120mm, the cross section of the lamp housing reflection cavity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical distance | aaaaa | aaaaa |

| Beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com