Environment-friendly granular magnesium passivation system

A granular magnesium, environmentally friendly technology, applied in the direction of furnace components, lighting and heating equipment, furnaces, etc., to achieve the effects of good fluidity, suitable flame retardant time, and not easy to pollute the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

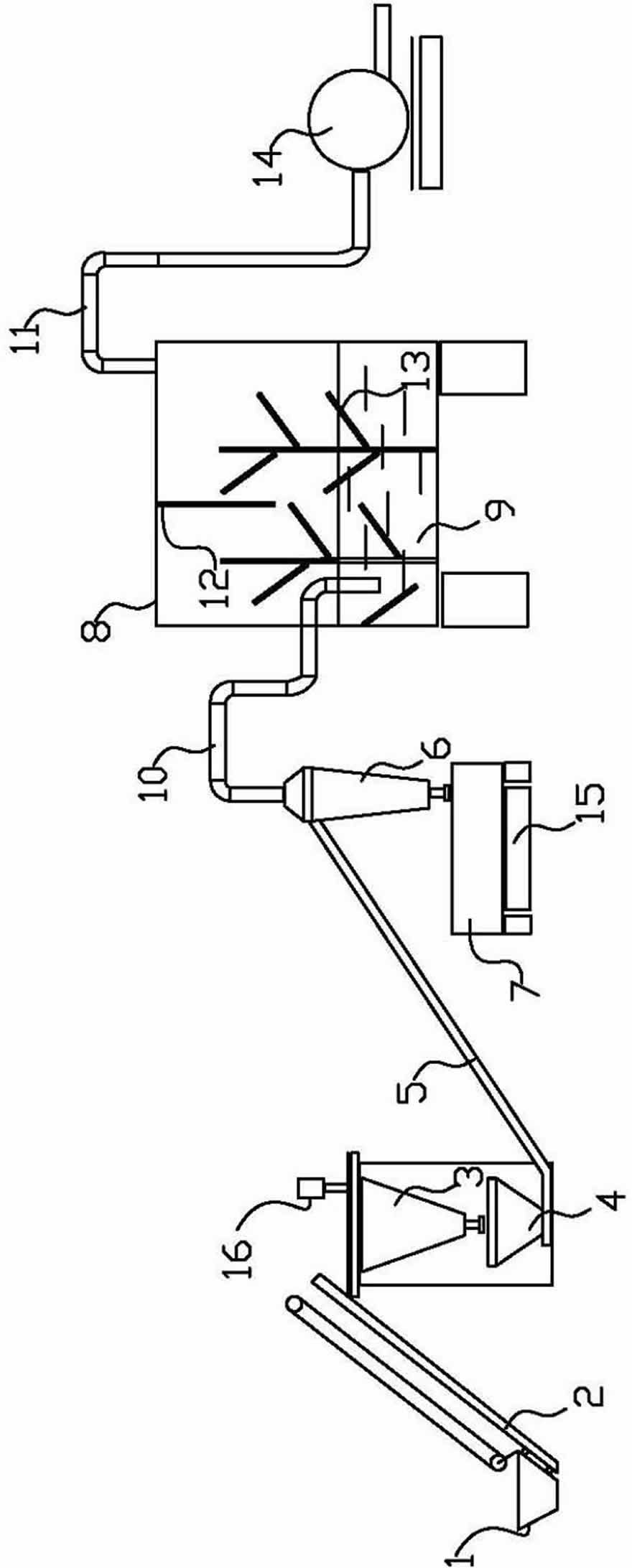

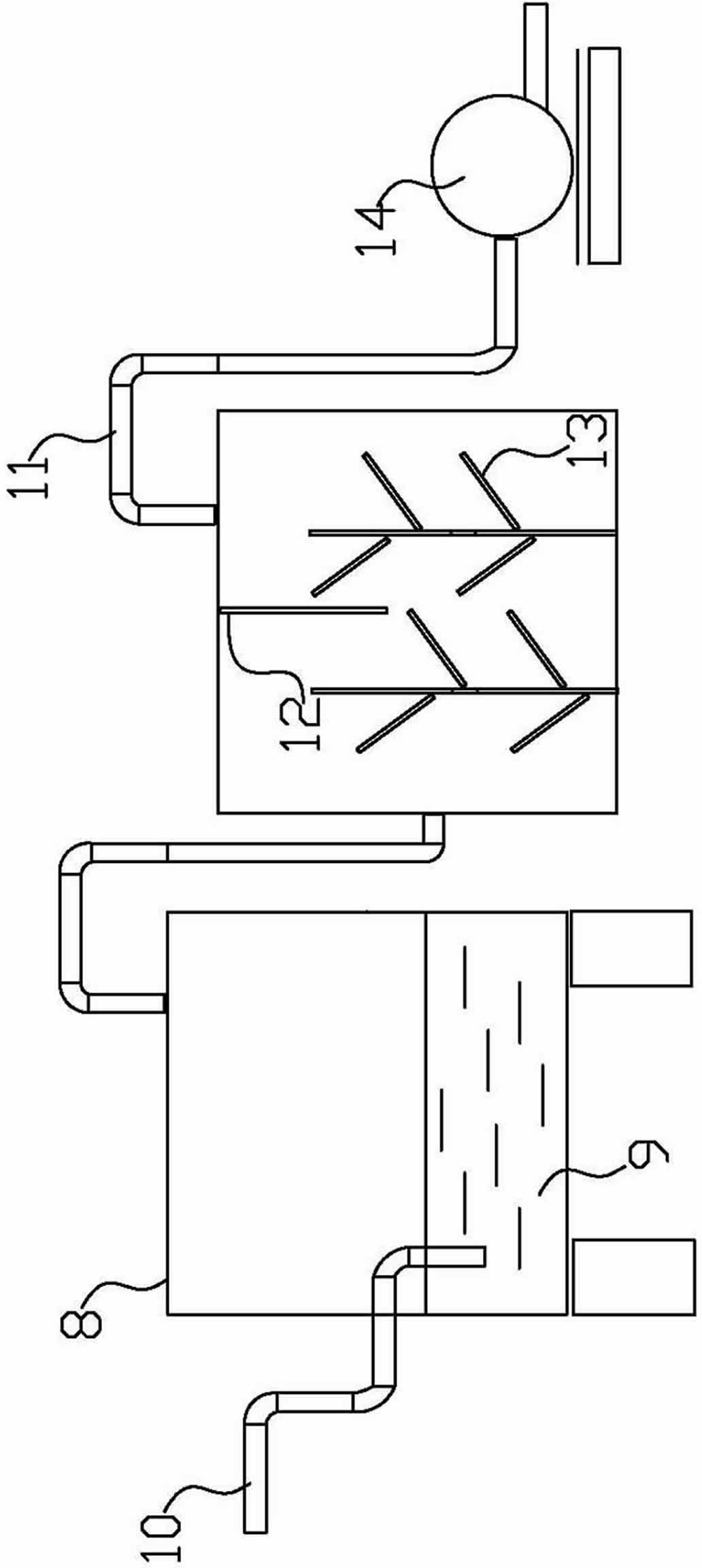

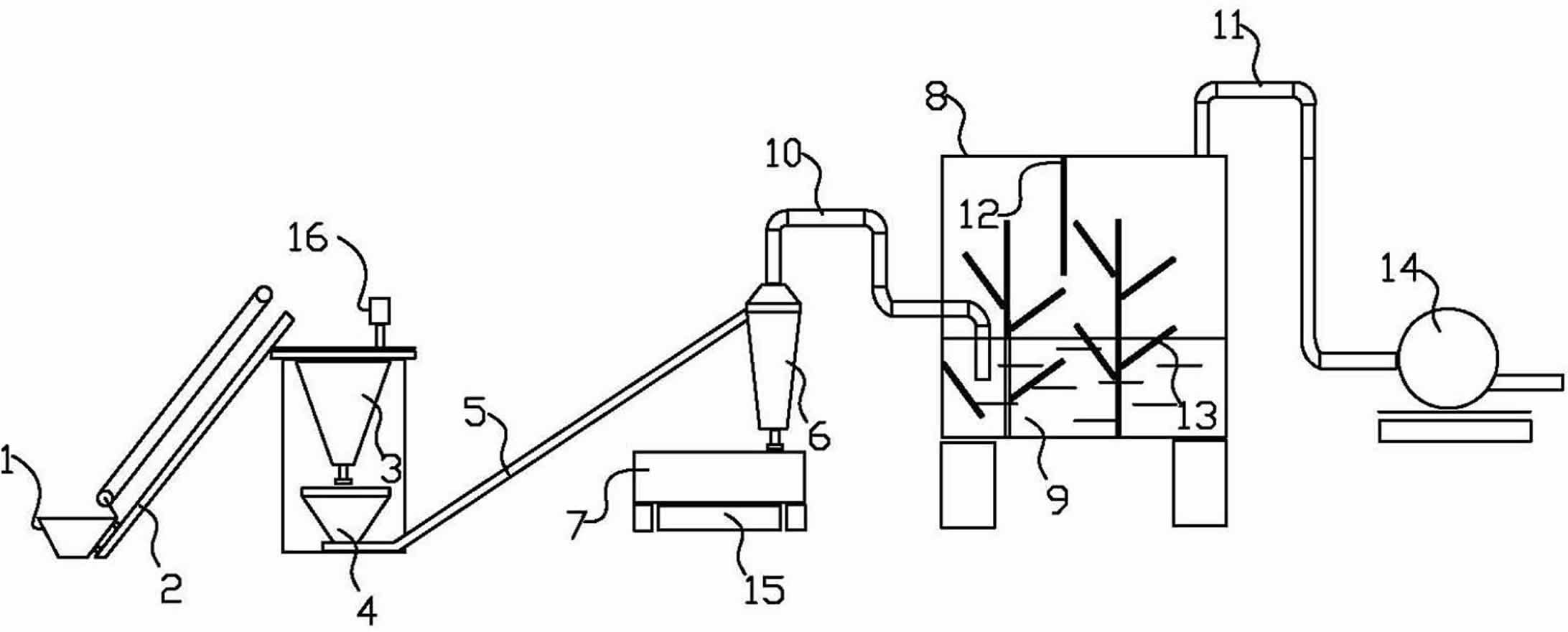

[0018] see figure 1 As shown, the environment-friendly granular magnesium passivation system includes: magnesium silo to be passivated 1, transmission mechanism 2, heating and stirring tank 3, passivated magnesium storage bin 4, separator 6, vibrating screen 7 and dust treatment device; The magnesium storage bin 1 to be passivated is connected with the transmission mechanism 2; the entrance of the heating and stirring tank 3 corresponds to the end of the transmission mechanism 2; The discharge port corresponds; the discharge port of the passivated magnesium storage bin 4 communicates with the feed port of the separator 6 through the heat dissipation conveying mechanism 5; the upper air outlet of the separator 6 communicates with the inlet of the dust treatment device; The outlet of the separator 6 communicates with the inlet of the vibrating screen 7 . In order to improve the separation effect, the separator 6 of the present invention adopts a cyclone separator.

[0019] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com